Completion method (I) Non-sand control wells

2024-02-09 10:00Completion method (I) Non-sand control wellscompletion

Well completion refers to the process of connecting the bottom of the well and the oil layer with a certain structure after the open hole well is drilled to the design depth. The quality of completion directly affects the production capacity and economic life of oil wells, and is related to the rational development of oil fields. According to the requirements of drilling procedures and development methods, the completion methods are divided into three categories: non-sand control well completion, sand control completion, and enhanced completion.

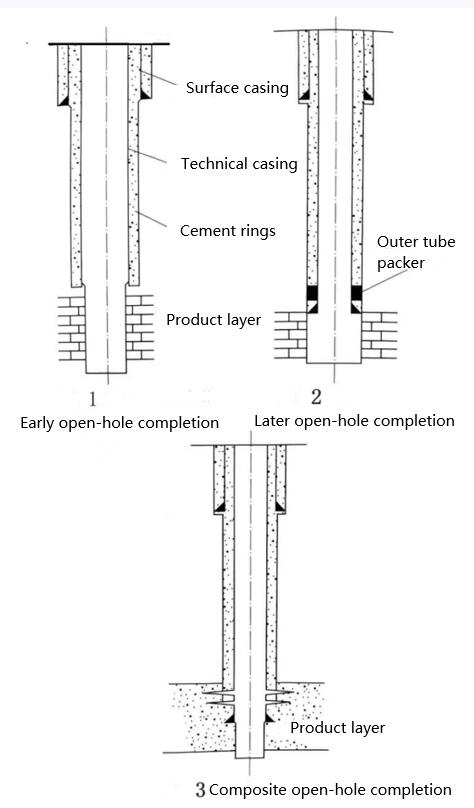

I. Open Hole completion method

(1). Early open-hole completion method

The early open hole completion method is to drill to the top of the oil layer, then inject cement into the casing, and then enter the drill bit with a smaller diameter from the casing after the cement slurry solidifies, and drill through the cement plug and the oil layer, as shown in Figure 1.

(2). Late open-hole completion method

Drill through the oil layer to the design depth, and then go down to the technical casing to inject cement cementing near the top boundary of the oil layer, as shown in Figure 2. In order to prevent the cement slurry from damaging the production layer below the casing shoe, the casing outer packer and water injection joint (or grading hoop) are usually installed at the lower part of the casing, or the drilling fluid with low water loss and high viscosity is substituted and a cement umbrella is used to prevent the cement slurry from sinking.

(3). Composite open-hole completion method

If there is a gas cap in the upper part of the production layer, an aquifer or an unstable interlayer at the top, the technical casing can be sealed through the oil and gas interface, and then the production layer can be opened and the lower open hole can be completed. If necessary, the upper oil-bearing section can be shot away, and this completion method is called composite completion, as shown in Figure 3.

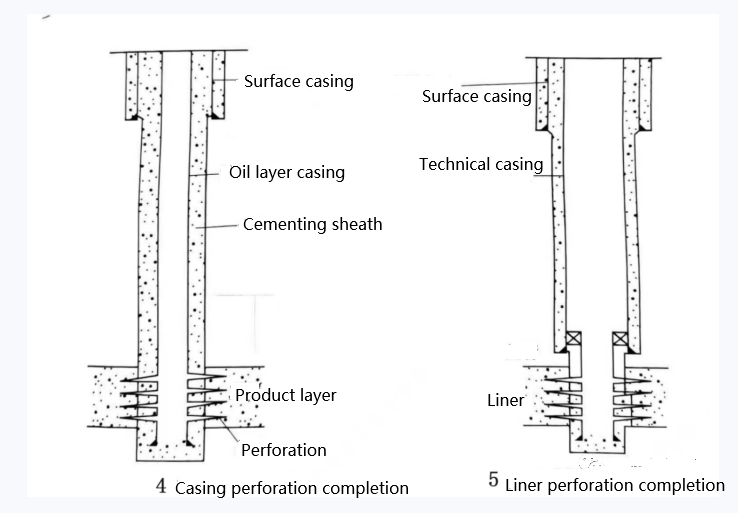

II. Casing cementing perforation completion

Casing cementing perforation completion refers to the completion method of connecting the production layer and the wellbore by using perforating bullets to shoot the casing and cement into the rock of the production layer to form an oil and gas flow channel after entering the casing of the oil layer under the production layer section and sealing the production layer with cement.

(1). Conventional casing cementing perforation completion

Perforation completion includes casing perforation completion and liner perforation completion, as shown in Figures 4 and 5. This completion method can be used for almost all types of reservoir rocks, and is currently the most widely used and widely adapted completion method. Liner perforation completion can reduce the amount of casing and oil well cement, which is conducive to protecting the oil layer, and most of the deep oil and gas wells are completed by this method.

(2). Expansion casing cementing perforation completion

It is a completion method that uses expansion casing as technical casing or completion casing to achieve the maximum completion inner diameter. The expansion casing can be used as the technical casing to optimize the wellbore structure and reduce the downhole complexity. The use of expansion casing as completion casing can effectively increase the inner diameter of the completion casing, and implement a series of measures such as layered mining and mechanical sand control.