Knowledge of drilling equipment---- Basic knowledge of drilling technology

2023-12-20 10:00Basic knowledge of drilling technology

Oil drilling: refers to the use of special equipment and technology, in a pre-selected surface position, drill a hole of a certain diameter downwards or on one side, until the underground oil and gas layer work.

Development of drilling methods:

(1) Artificial digging: before 1521.

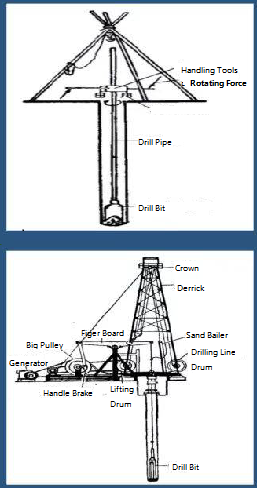

(2) Manpower percussion drill: 1521~1835, it was completed by manpower, sand fishing cylinder, special drill bit, suspension rope, traveling beam, etc.

(3) Mechanical drilling (punching drilling): 1859~1901, relying on mechanical impact to break the rock, rock breaking and clear rock interphase.

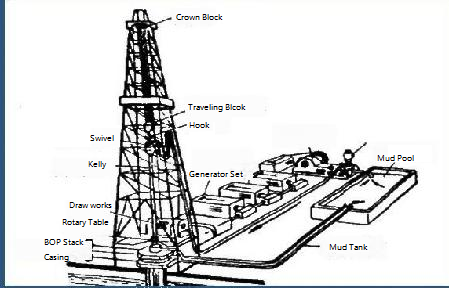

(4) Rotary drilling: developed in 1901, rotary drilling is driven by power to drive the drill bit to rotate. A drilling method that crushes the rock at the bottom of the well while circulating the drilling fluid to clean the bottom of the well during rotation. Rotary drilling is further divided into turntable drilling, downhole power drilling tool drilling, and top-drive rotary drilling.

Drilling construction process

Pre-drilling construction

1. Fix the well position

2. Road survey

3. Foundation construction

4. Moving

5. Installation

Drilling construction

6. First Drill

7. Second drilling

8, Drilling

9. Drilling

10, Change the drill bit

11, Drilling

Completion construction

12. Completion electrical measurement

13. Casing cementing

Drilling is the process of using drilling rig equipment and rock breaking tools to break the formation to form a wellbore, and the purpose is to carry out it

Geological evaluation, discovery of oil and gas reservoirs, and development of oil and gas reservoirs. Construction process: drilling, → washing, → receiving a single root, starting and drilling →, and drilling → completed.

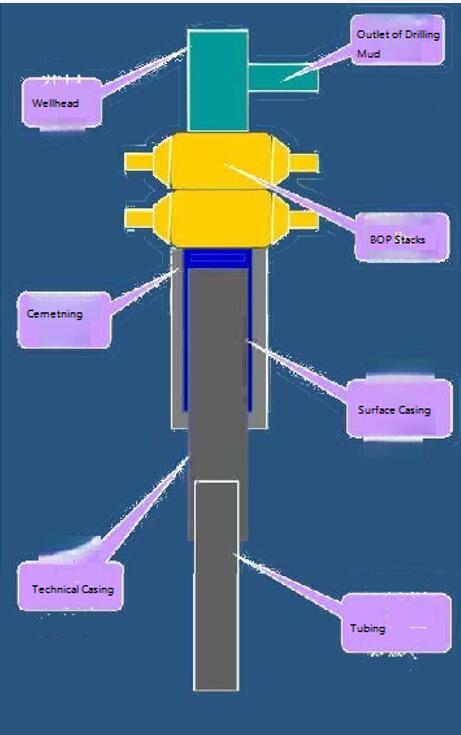

Cementing is to put a casing string of a certain size into the well, and inject cement slurry around it to fix the casing on the wall to avoid the collapse of the wellwall.

Construction process: lower the casing to a predetermined depth

Degree → cement head, circulating mud,

The grounding pipeline → injected with isolation liquid→ cement → top rubber plug→ for the mud → pressurized→ cement injection ended, waiting for solidification.

Conduit: used to lead drilling fluid to solid control equipment, the depth is generally less than 10 meters. It is generally done during pre-drilling preparation.

Surface casing: its function is to seal the easy to collapse and leak formation and water layer of the surface part, install the wellhead device of the second drilling, and control the blowout. The depth of its penetration is determined according to the depth of the soft and easily collapsed and leaky stratum and water layer of the surface part. Generally around 100 meters. Technical casing: used for sealing complex formations that are difficult to control with slurry; Severely leaking layers that cannot be plugged; oil and gas reservoirs that are not in the target layer; The pressure difference is huge, oil, gas, water layer, etc. Oil casing: It is used to separate oil, gas and water layers with different pressures and different properties to establish a channel for oil and gas flow to the surface to ensure long-term production and meet the requirements of reasonable exploitation of oil and gas and production stimulation measures. The depth of the casing in the reservoir depends on the depth of the target layer and the different completion methods.