Knowledge of drilling equipment--Drilling fluid solid control system and tools 2

2024-01-29 10:00Shale shaker

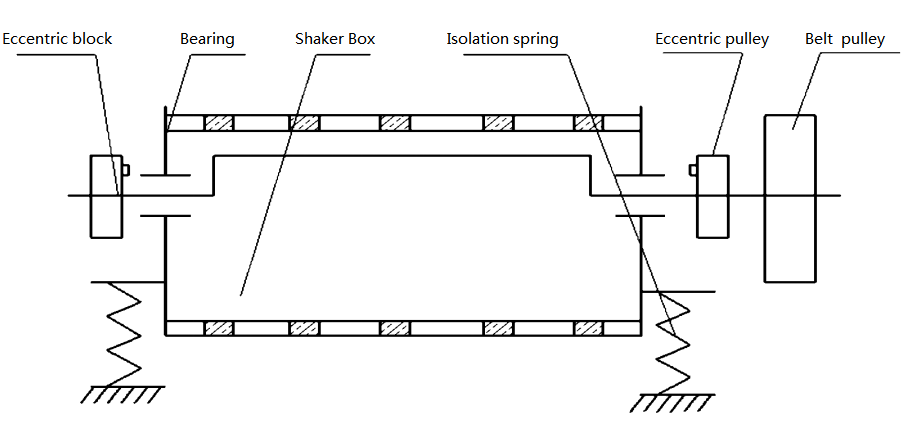

Schematic diagram of the structure of the shale shakerShale shaker

The shale shaker mainly drives the exciter to rotate through the motor, produces the inertial force of periodic change, and the solid particles of the drilling fluid enter the shaker surface, and do a throwing motion on the shaker surface, and the solid particles of different sizes are classified and removed. The separation diameter and processing capacity of the shale shaker are important factors.

Selection of shale shaker

The technical level of the shale shaker is mainly reflected in the processing capacity (processing capacity and separation particle size) and the stability of the operation. The length of life and the flexibility of operation. The processing capacity of the shale shaker is related to the structure of the shale shaker, the movement trajectory, the vibration frequency, the shale intensity, the area of the shaker and the thickness of the shaker. In order to match the shale shaker with the drilling rig, it is necessary to consider the maximum displacement of the drilling pump and the amount of cuttings generated during drilling,

namely:

Q shaker > Q pump + Q chips

Where: Q shaker - shale shaker Capacity, L/s;

Q pump - maximum displacement of drilling pump, L/s;

Q cuttings – the amount of cuttings in drilling, L/s.

Usually, according to the movement trajectory of the shaker frame, the shale shaker is divided into four categories: circular shaker, ordinary elliptical shaker, linear shaker and balanced elliptical shaker.

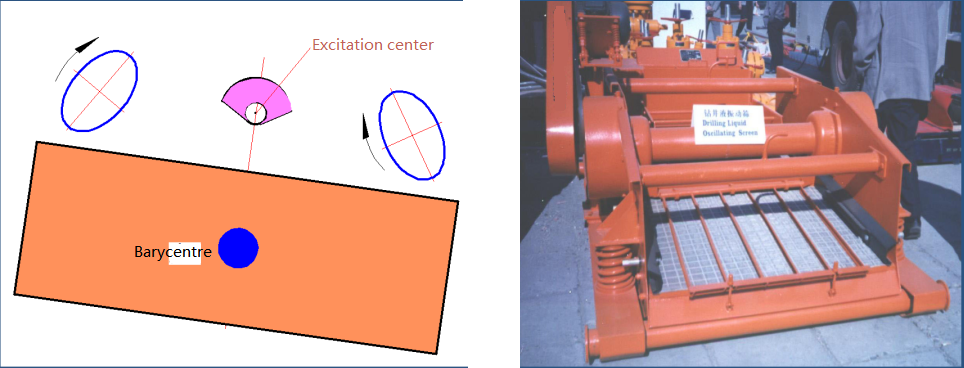

Ordinary elliptical shaker: also known as unbalanced elliptical shaker, is fixed with excitation device directly above the center of mass of the shaker box. It requires the shaker box to be tilted at an angle and the sand is forcibly discharged by gravity, so that the sand particles do not have a tendency to be thrown backwards. As a result, the tilting of the shaker box does improve the movement of the sand particles, but the amount of drilling fluid processed by the vibrating shaker is reduced, which is the main disadvantage of ordinary elliptical shakers.

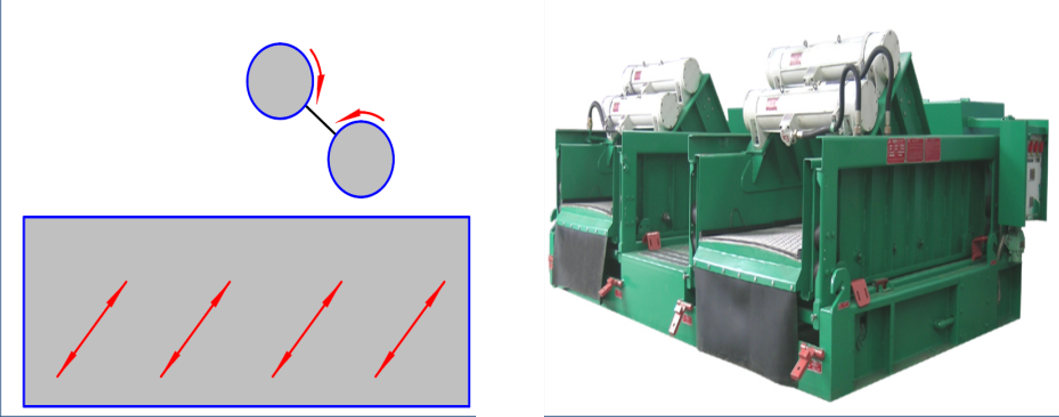

Linear shale shaker: two main shafts with eccentric blocks are synchronously counter-rotated to produce linear vibration, because the shale direction of linear shaker is unchanged, the particles that are stuck in are not easy to fall off, and the phenomenon of "shaker paste" appears, so that the effective flow area of the shaker is reduced, resulting in the decrease of treatment capacity, and when the number of shaker mesh increases, the shaker paste phenomenon will be more serious. Therefore, when the linear shaker uses ultra-fine mesh shaker, it is impossible to meet the requirements of drilling fluid consumption.

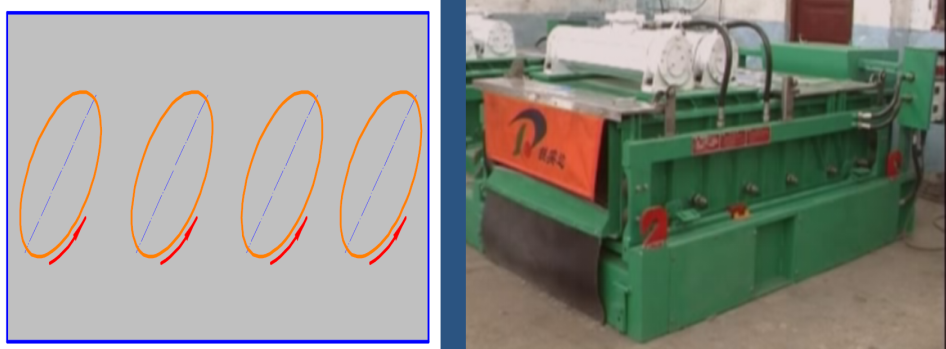

Balanced elliptical shaker: It is a new shaker type developed in recent years, the movement trajectory of each point on the shaker box is shown in the figure, and the long axis and short axis of the movement trajectory of all elliptical are the same.

The magnitude and direction of the throwing angle are exactly the same. Balanced elliptical shaker combines the basic advantages of circular shale shaker and linear shale shaker, the processing capacity of balanced elliptical shaker is 20-30% larger than that of linear shaker, is a relatively advanced drilling fluid shale shaker, representing the development direction of today's drilling fluid shale shaker.