Overview of API 5CT Casing and Tubing Specifications

2024-05-21 10:00Overview of API 5CT Casing and Tubing Specifications

The API 5CT standards are crucial technical guidelines for steel casings and tubing pipes, which are essential components in the drilling and extraction ofCasing oil and gas from wells. These specifications not only cover the dimensions and materials for casings and tubing but also extenTubingd to Casingadditional elements like pup joints, coupling stock, and accessories. The standards delineate three levels of product specifications: PSL-1, PSL-2, and PSL-3, with PSL-1 forming the foundational requirements.

Commonly Used Steel Grades

- J55/K55

- N80/N80Q/L80

- C90

- R95/T95

- P110/C110

- Q125

Connection Types as per API SPEC 5B

- SC: Short round thread casing

- LC: Long round thread casing

- BC: Buttress thread casing

- NU: Non-upset tubing

- EU: External upset tubing

- IJ: Integral tubing connections

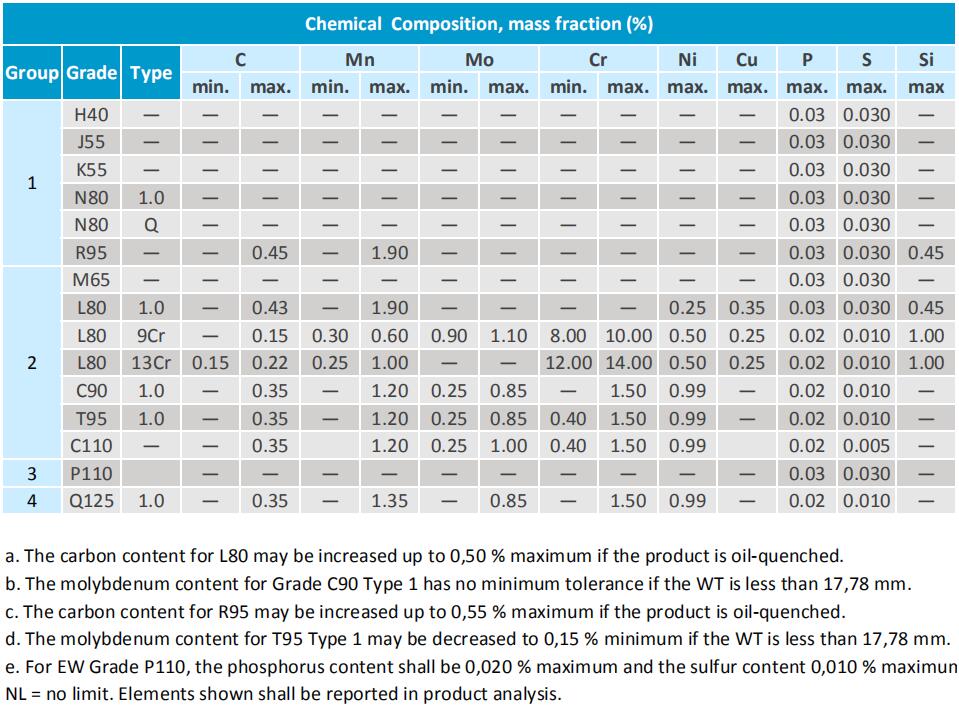

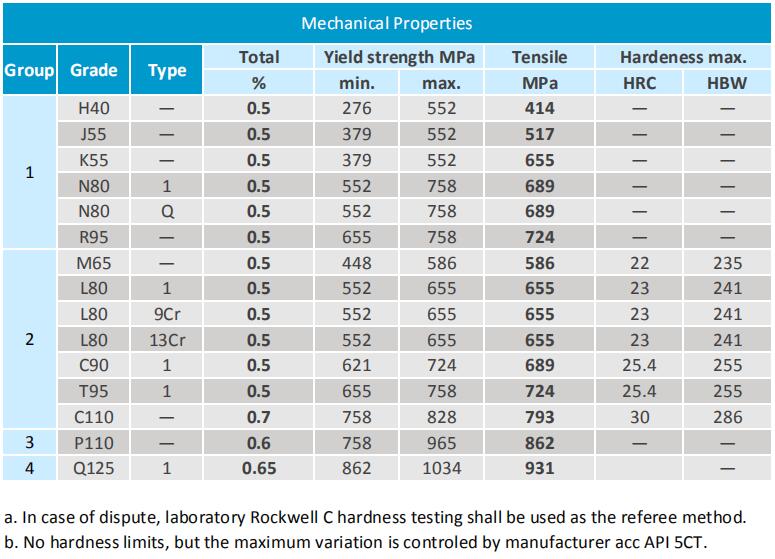

Grade Classifications

- Group 1: Grades H, J, K, N, and R

- Group 2: Grades C, L, M, and T

- Group 3: Grade P

- Group 4: Grade Q

Manufacturing Standards

The API 5CT stipulates that steel used for pipe billets must undergo grain refinement, incorporating elements like aluminum, niobium, vanadium, or titanium to enhance the steel's grain structure.

- Pipes are to be produced as seamless or EW type.

- All couplings and related materials should be seamless.

- Cold-drawn tubing must be heat-treated to meet quality standards.

- Seamless pipes are preferred for casing and tubing attachments unless specified otherwise.

Heat Treatment Practices

Different grades of API 5CT casing and tubing require specific heat treatment methods. Full-body and full-length heat treatments are mandatory for products needing such processes. Upset products must be heat-treated post-upsetting, and coupling blanks can be heat-treated separately.

Grade-Specific Heat Treatment Requirements

- N80 Type 1: Normalized or normalized and tempered (manufacturer's discretion).

- N80Q and R95: Quenched and tempered.

- L80: Risk of embrittlement when tempered below 620℃ (1150°F).

Straightening Procedures

- R95: Limited to normal straightening and minimal compression cold working.

- M65 and L80: Straightening allowed post-heat treatment.

- C90 and T95: Can be straightened with subsequent stress relief heating.

- C110: Requires stress-relief or hot straightening as per specified temperatures.

- Q125: Allows gag-press or hot-rotating straightening with temperature controls.

Chemical Composition and Tensile Properties

Products must adhere to the specified chemical composition and meet the tensile performance criteria outlined in the API 5CT standards. The mechanical properties of the upset regions should match those of the pipe body, with elongation being the exception.

Dimensions, Masses, and Pipe End Specifications

The API 5CT provides detailed charts for casing dimensions, weights, and tubing specifications. Pipes are named according to their outer diameters, with specific tolerances for upset and integral tubing connections.

Quality Assurance Measures

All measuring equipment must be verified regularly to ensure precision. In cases of abnormal conditions, recalibration or re-verification is required.

Wall Thickness and Pipe Ends

- Wall thickness tolerance: -12.5%.

- Flat-end pipe: Must meet the steel grade requirements, with or without upset ends.

- API Threads: Available in short or long threads for certain steel grades.

- Rounded Nose: Optional rounded pipe ends to replace conventional corner breaks.