Precautions For Use Of Non-magnetic Drill Collars

2024-08-21 10:00Precautions For Use Of Non-magnetic Drill Collars

1. After use, remove the mud and dirt, check the safety of each part, then apply anti-rust oil, and store in a dry and ventilated place.

2. During the on-site inspection, if one of the conditions for judging repair or scrapping occurs, the drill collar should be recycled for repair or scrapped.

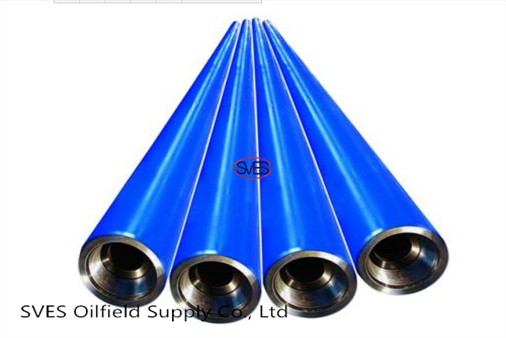

3. In order to ensure the accuracy of the measurement results of the magnetic instrument, the length of the non-magnetic drill collar must be reasonably selected.Drill Collar

Detail 1. Drilling and oil exploration is a very serious matter, so every detail must be as accurate as possible. The requirements for drilling tools such as non-magnetic drill collars are also very strict. In order to ensure the accuracy of the measurement results of magnetic measuring instruments such as non-magnetic drill collars, the length of the non-magnetic drill collarNon-manetic Drill Collar must be reasonably selected. The length of the non-magnetic drill collar should be selected according to the size of the well inclination angle and well inclination azimuth of the measuring section. When the well inclination angle is large, the length of the non-magnetic drill collar should be lengthened.

Detail 2. When a centralizer is needed in the middle of the non-magnetic drill collar, attention must be paid to the influence of the centralizer on the magnetic measuring instrument. The best way is to make the centralizer into a non-magnetic drill collar core plus a steel sleeve, which can reduce the influence on the magnetic measuring instrument and save the price of non-magnetic steel.