Revolutionizing Oilfield Operations: SVES's Cutting-Edge Wireline Downhole Tools and Coiled Tubing Technology

2023-12-14 10:00Revolutionizing Oilfield Operations: SVES's Cutting-Edge Wireline Downhole Tools and Coiled Tubing Technology

In the dynamic world of oilfield operations, efficiency and innovation are paramount. SVES Oilfield Supply Co., Ltd stands at the forefront of this industry, consistently pushing the boundaries of what's possible with its advanced coiled tubing technology and a comprehensive suite of wireline downhole tools. As we delve into the remarkable achievements of SVES, let's explore how their state-of-the-art equipment has been instrumental in setting new standards and enhancing oilfield productivity.

**The Power of Coiled Tubing Technology**

SVES's coiled tubing technology has revolutionized traditional oilfield operations with its rapid deployment capabilities, exceptional efficiency, and minimal environmental footprint. This technology allows for pressurized operations, safeguarding oil and gas reservoirs while ensuring a safer and more eco-friendly approach to well servicing. The South 1st District production block operation is a testament to the prowess of SVES's coiled tubing, where it has not only set new records but also rejuvenated older oilfields with its innovative applications.

**Integrating Advanced Wireline Downhole Tools**

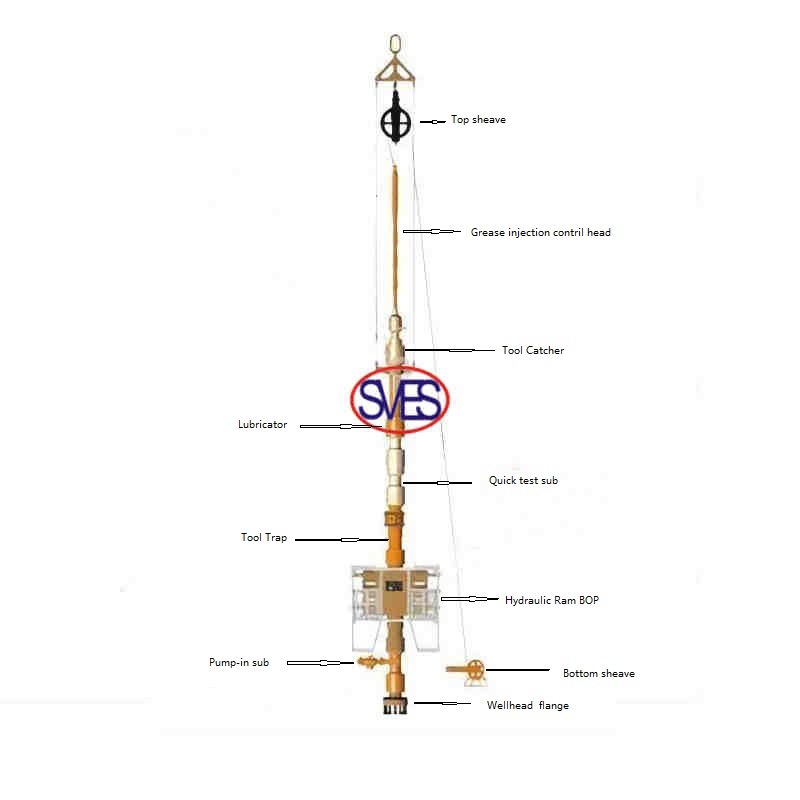

The integration of wireline downhole tools such as the **Lifting Tool**, **Hoisting Tool**, and **Top Sheave** has been pivotal in enhancing the operational capabilities of SVES. These tools, along with the **Grease Injection Seal Head**, **Hand Pump**, and **Hydraulic Tool Catcher**, ensure seamless and efficient well interventions. The **Lubricator** and **Hydraulic Tool Trap** play crucial roles in maintaining tool integrity, while the **Quick Test Sub** and **Diesel Engines Air Compressors** provide reliable power sources for extended operations.

SVES's commitment to excellence is further demonstrated by its **Hydraulic and Grease Control System**, which optimizes tool performance and ensures precise control during complex procedures. The **Pump-in Sub** and **Bottom Sheave** facilitate smooth wireline conveyance, while the **Wellhead Crossover Flange** ensures secure connections between various components.

**Elevating Safety and Performance with Hydraulic BOPs**

Safety is a non-negotiable aspect of oilfield operations, and SVES has addressed this by incorporating the **Hydraulic Double Ram BOP** and **Hydraulic Triple Ram BOP** into thHydraulic Double Ram BOPeir arsenal. These blowout preventers provide multiple layers of security, mitigating risks and enhancing the safety of personnel and the environment.

**Achievements and Future Outlook**

SVES's coiled tubing technology has led to the creation of 27 supporting process technologies across three categories, achieving remarkable feats such as 39 layers of vertical well subdivision fracturing and fracturing 94 sections of pipe string in a single trip. These accomplishments have propelled the Hydraulic Triple Ram BOPoverall operating efficiency by over 30%, setting new benchmarks for the industry.

Despite challenging conditions, such as severe wind and snow, SVES's dedicated employees have diligently implemented "eight precautions" measures, ensuring high-quality construction amidst adverse weather. The Downhole Operations Branch's completion of overhauls on 2,208 wells, 975 large-scale fracturing wells, and 4,242 conventional fracturing wells this year, surpassing all production targets, is a clear indicator of SVES's unwavering commitment to excellence.

As SVES continues to innovate and lead the way in oilfield technical services,Wireline Lifting Tool its coiled tubing technology and wireline downhole tools will undoubtedly remain essential components in the quest for enhanced oil recovery and sustainable energy production.