SVES Oilfield Supply Co., Ltd Double Acting Sucker Rod Pump

2024-01-07 10:00Double Acting Sucker Rod PumpSucker Rod PumpSVES Oilfield Supply Co., Ltd Double Acting Sucker Rod Pump

Application:

1)The oil wells with high fluid production.

2)The oil wells with ordinary oil pumps.

3)The oil wells can realize double-layer recovery.

Characteristics:

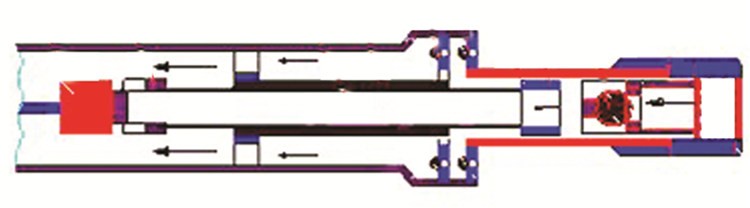

It is divided into two working chambers by sealing device which can completes two oil suction and two oil discharge actions in a reciprocating stroke.

1)Compared with ordinary single-acting pumps with the same diameter, the theoretical displacement is increased.

2)It can realize double-layer recovery.

Description:

Double-acting sucker rod pump

A special structure is used to complete the two oil suction and two oil discharge actions in a reciprocating stroke, which can realize a double-layer recovery.

double acting sucker rod pump

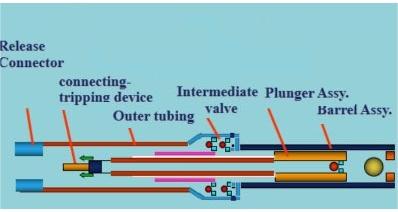

The reciprocating double-acting oil pump, including a small pump barrel, a small plunger, a large pump barrel, a large plunger, a fixed valve, a traveling valve and an upper oil outlet valve cover, is characterized in that:

Double acting rod pump

The lower end of the outer pipe passes through a The number coupling is connected and fixed with the upper end of the three-button joint,

The lower end of the small pump barrel is fixedly connected with the inner wall of the upper port of the three-button joint,

The lower end of the three-button joint is fixedly connected with the upper end of the upper short tube,

and the lower end of the upper short tube passes through No. 2 The coupling is connected and fixed with the upper end of the large pump barrel,

The lower end of the large pump barrel is connected and fixed with the upper end of the lower short pipe through the third coupling,

The lower end of the lower short pipe is connected and fixed with the fixed valve through the lower coupling,

and the lower end of the small plunger The two-way core assembly is connected and fixed with the upper end of the large plunger,

The lower end of the large plunger is fixed with a traveling valve, the side wall of the large pump barrel is provided with an oil inlet, and the two-way core assembly is located in the upper short pipe.

In the cavity, the utility model has a simple and reliable structure, a more stable working performance, and improves the efficiency of oil extraction.