SVES Oilfield Supply Co., Ltd THD Tubing Pump

2023-12-30 10:00SVES Oilfield Supply Co., Ltd THC Tubing Pump

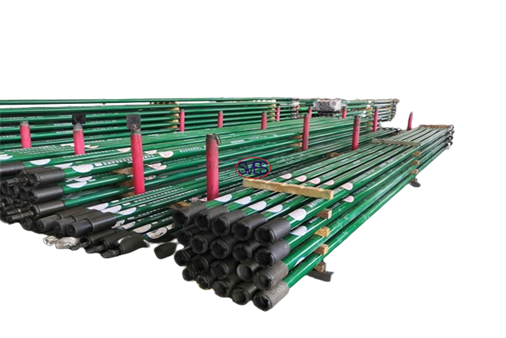

THD Tubing Pump

The outer cylinder, bushing, and suction valve of the tubing pump are assembled on the ground and enter the well at the lower part of the tubing.

The plunger, fixed valve, and sucker rod are then pumped through the tubing into the pump.

The bushing is machined into sections and lined into the outer barrel.

The plungers are hollow cylinders made of seamleTHD Tubing Pumpss steel tubes with smooth circular grooves on the outside surface to allow sand particles to enter the circular grooves between the plungers to prevent sand particles from wearing away the plunger and bushing, and to store oil in the circular grooves as a lubricant.

THD tubing pump is equipped with oil drainers, which are used to drain the oil from the pipe.

The pump structure is simple, low cost, so suitable for low depth, high production Wells.

THD Tubing Pump

The outer cylinder, bushing, and suction valve of the tubing pump are assembled on the ground and enter the well at the lower part of the tubing.

The plunger, fixed valve, and sucker rod are then pumped through the tubing into the pump.

The bushing is machined into sections and lined into the outer barrel.

The plungers are hollow cylinders made of seamless steel tubes with smooth circular grooves on the outside surface to allow sand particles to enter the circular grooves between the plungers to prevent sand particles from wearing away the plunger and bushing, and to store oil in the circular grooves as a lubricant.

THD tubing pump is equipped with oil drainers, which are used to drain the oil from the pipe.

API standard sucker rod pump painting and marking

The pump structure is simple, low cost, so suitable for low depth, high production Wells.

The TH tubing pumps feature heavy-walls and full-barrels.

These pumps can be assembled with:

•Box-end and pin-end plungers;

•mechanical seating assemblies;

•Tap-type or lock-type, standing-valve pullers;

All-metal, heavy-wall-barrel tubing pumps combine heavy-duty construction and a stroke-through design with the largest bore possible for any given tubing size to maximize production.

The one-piece barrel eliminates joints susceptible to failure under working loads and is precision honed from end to end to ensure a perfect bore for the plunger and increase pumping efficiency.

APPLICATION:

These pumps are recommended for the following applications:

• Wells where greater capacity is needed in a given tubing size

• Wells of any depth with severe pumping conditions

• Wells with scale problems

• Deep wells

Data Speicification:

| Pump code | 25-106TH | 25-125TH | 25-150TH | 25-175TH | 25-200TH | 25-225TH | 30-250TH | 30-275TH | 40-325TH | 40-375TH |

| Basic pump diameter | 1 1/16 | 1 1/4 | 1 1/2 | 1 3/4 | 2 | 2 1/4 | 2 1/2 | 2 3/4 | 3 1/4 | 3 3/4 |

| -27 | -31.8 | -31.8 | -44.5 | -50.8 | -57.2 | -63.5 | -69.9 | -82.6 | -95.3 | |

| Plunger length | ≤26(7925) | |||||||||

| Pump barrel length | ≤34(10363) | |||||||||

| Stroke ft (mm) | ≤32(9754) | |||||||||

| Connecting tubing thread | 2 7/8 NU(EU) | 3 1/2 NU(EU) | 4NU | 4EU | ||||||

| Connecting sucker rod thread | 3/4 in | 7/8 in | 1 in | |||||||

| Theoretical displacement | 0.824 sn | 1.140 sn | 1.642 sn | 2.235 sn | 2.918 sn | 3.694sn | 4.560 sn | 5.518 sn | 7.707 sn | 10.261 sn |

| Maximum outer diameter (mm) | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4.25 | 4.25 | 4.5 | 4.6 |

| -88.9 | -88.9 | -88.9 | -88.9 | -88.9 | -88.9 | -108 | -108 | -114.3 | -117 | |