Tubing Anti-eccentric Wear Rotator

2024-09-11 10:00Tubing Anti-eccentric Wear RotatorTubing Anti-eccentric Wear Rotator

With the increasing number of horizontal and deviated wells in oilfields, the eccentric wear between sucker rods and tubing in deviated well sections emerges. The tubing wears out rapidly at the eccentric wear position, leading to tubing perforation damages and well production halt. This causes considerable economic losses to the oilfield production. The FPM-25 Tubing Anti-eccentric Wear Rotator is a newly developed manual-driven tubing anti-eccentric wear device to improve the tubing worn out.

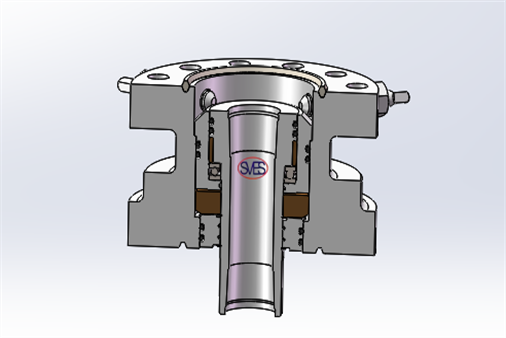

This device consists of a driving mechanism: worm gear, worm, rotating tube and flange housing, and a suspension mechanism: suspender, thrust bearing, etc.

Specifications of Wellhead Tubing RotatorWellhead Tubing Rotator | |

Size and Model | FPM-25 |

Working pressure | Not more than 25MPa |

Applicable oil tubing | Φ73mm |

Applicable pump hanging depth | ≦2800m |

Operating torque of the handle | ≦30Nm(20MPa) |

Transmission ratio for the worm wheel and the worm | 1:52 |

Maxi. workload | ≦367kN |

Net weight | 180kg |

Features:

It features a simple structure, light weight, reliable performance and accuracy. No special maintenance is required during the operation. It is a product integrating the advantages of numerous tubing rotators domestic and oversea market.

When the operating handle is manually operated, the worm rotates clockwise, thereby driving the worm gear and the rotating tube to rotate together, and the rotating tube drives the downhole tubing to rotate by a certain angle in the clockwise direction. This changes the original friction and wear from wear at a certain fixed position and fixed angle to relatively uniform wear along the inner circumference of the tubing, distributing the wear area from one point to the entire inner circumferential surface. Thus, eccentric wear is effectively prevented, and the service life and workover period of the tubing are prolonged.