What Are the Hazards of Wax Deposition in Oil Wells?

2024-09-12 10:00What Are the Hazards of Wax Deposition in Oil Wells?

Before discussing the hazards of wax deposition in oil wells, let's first understand what paraffin wax is. Paraffin wax (CnH2n+2) mainly consists of straight-chain alkanes (about 80%–95%), with small amounts of branched alkanes and monocyclic naphthenes with long side chains (both combined less than 20%). The primary components range from C16 to C64 alkanes (C16H34 to C64H130). Pure paraffin wax appears as a white, slightly translucent crystalline solid with a density of 880–905 kg/m³ and a melting point of 49–60°C. It is insoluble in water but can dissolve in ether, benzene, and certain esters.

Paraffin wax is a significant component of crude oil. During the extraction process, when crude oil containing a certain amount of dissolved paraffin wax undergoes a reduction in temperature and pressure, along with gas release, the dissolved wax tends to crystallize, grow, aggregate, and deposit on solid surfaces like the walls of pipes, causing what is known as the wax deposition phenomenon.

Hazards of Wax Deposition in Oil Wells:

1. Wax Deposition in Wellhead and Surface Pipelines: Wax deposition increases the backpressure at the wellhead and increases the head pressure of deep well pumps.

2. Wax Deposition at the Outlet of Deep Well Pumps: This leads to increased friction loss along the oil tubing and increases the load on the surface drive system.

3. Wax Deposition at the Lower Pump Position: The suction conditions of the pump deteriorate due to wax deposition.

4. Wax Deposition Below the Pump Intake: This reduces pump efficiency and can easily cause pump burnout.

5. Impact on Production: Wax deposition reduces the diameter of oil pipes and increases the external diameter of the sucker rod, leading to increased flow resistance. This reduces oil production, and in severe cases, can block the well completely, causing a stuck pump. Wax deposition in deep well pumps can cause pump leakage, reducing the pump filling coefficient and the production capacity of the oil well.

6. Impact on Suspended Load: In the production process of beam pumping wells, severe wax deposition in the oil pipe increases frictional resistance in the waxed section. This increases the suspended load during the upstroke and decreases it during the downstroke, resulting in increased alternating load due to waxing, affecting the service life of the sucker rod.

7. Erosion and Wear of Rods and Tubing: Wax deposition can lead to eccentric wear between the rods and tubing, increasing the workload of maintenance operations.

In summary, wax deposition in oil wells can cause significant operational challenges and impact the overall efficiency and productivity of oil extraction processes.

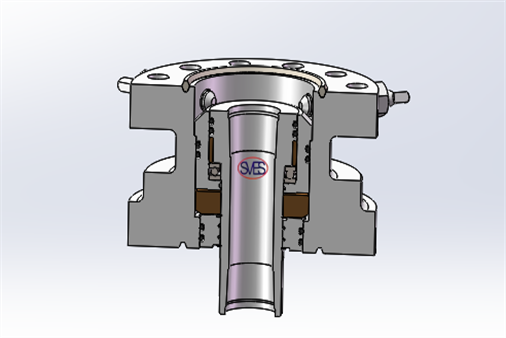

SVES Oilfield Supply Co., Ltd could provide Wellhead Tubing Anti-Eccentric Wear RotatorTubing Anti-Eccentric Wear Rotator could provent tubing worn out to protect the tubing and increasing the tubing production life.