Pigging Valve (Trunnion Block-Mounted Ball Valve)

Pipeline pigging Valve

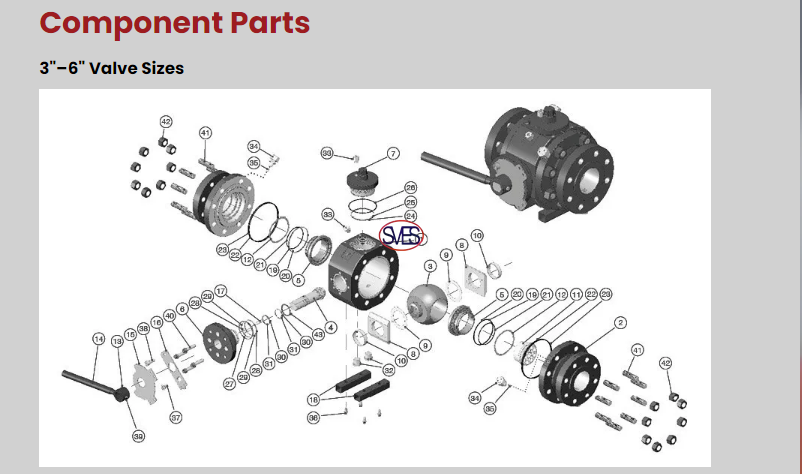

1. Specification

The petroleum pipeline pigging Valve is a special valve used for cleaning petroleum pipelines. It has the following characteristics:

1.1 Reliable sealing performance to prevent oil leakage during the cleaning process.

1.2 High corrosion resistance to withstand the corrosive medium in the petroleum pipeline.

1.3Simple structure, easy to maintain and operate.

2. Designed Engineered, manufactured and tested to API 6D

2.1 Industry Standards: API 6D, ASME B16.34 and API 598

2.2 Meets NACE MR0175-03

2.3 Positive Shut Off

2.4 Trunnion Block mounted Ball for reduced torque and stem loading

2.5 Large Bearings for smooth robust operation

2.6 Up Stream sealing with automatic downstream cavity relief

2.7 Double Block and Bleed with vent and drain capabilities

2.8 Large button head grease fittings with buried checks

2.9 Emergency seat sealant injection

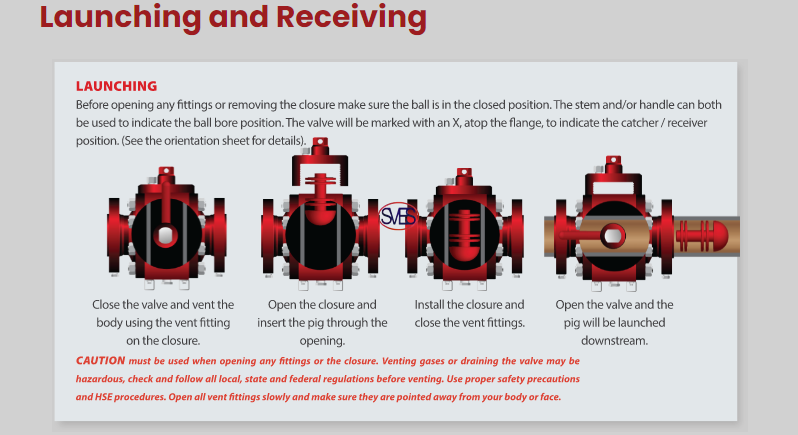

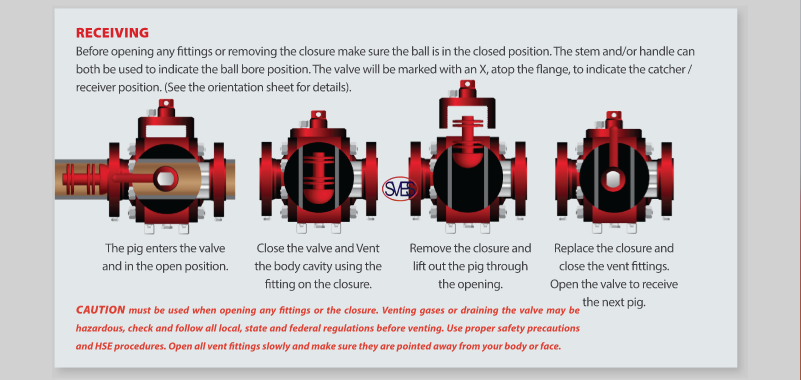

2.10 Pig Entry Cap with vent

2.11 Pig Entry Cap with hex drive and spanner drive options

2.12 Open and Closed lockable stop plates 2”- 6”

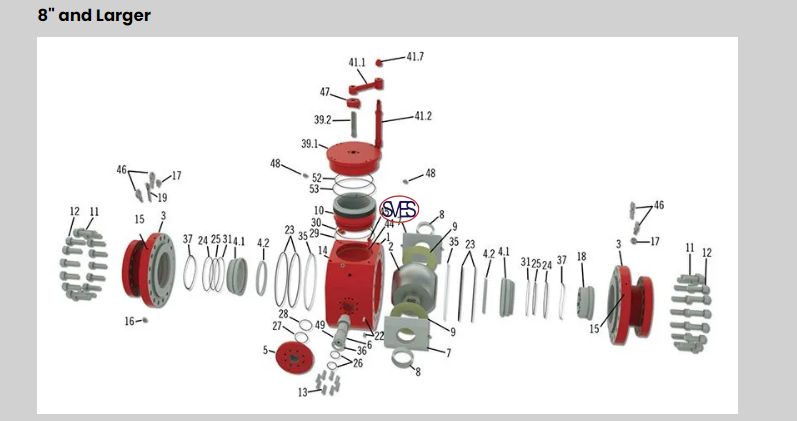

2.13 6” and larger utilize a body cavity equalization valve

2.14 Large Actuator Mounting Pads and Stems

2.15 Accepts Bullet, Spherical, and Double-Dish pigs

2.16 Suitable pigs are fabricated to fit all SVES pig valves.

3. Parameter specifications

The parameter specifications of the petroleum pipeline pigging Valve include the following aspects:

3.1 Valve model: different models are available for selection based on the pipe diameter and pressure level.

3.2 Valve material: usually made of corrosion-resistant stainless steel or alloy material.

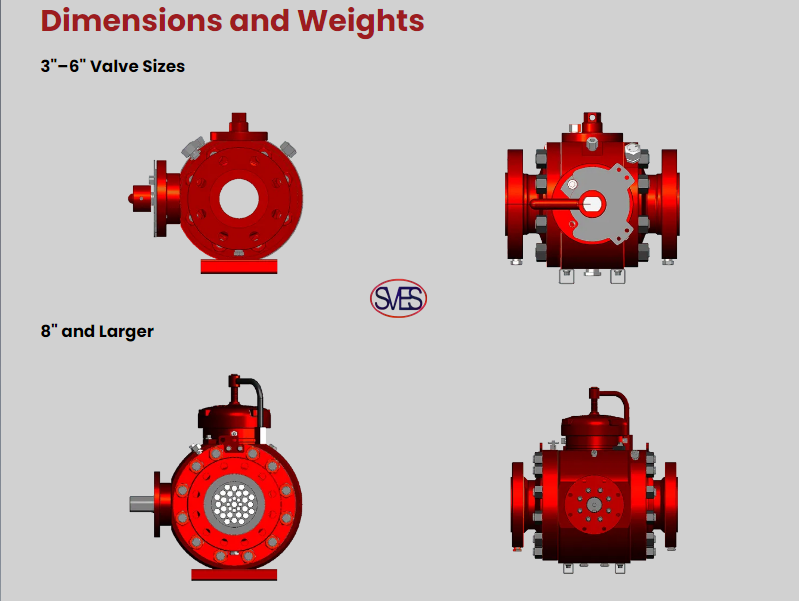

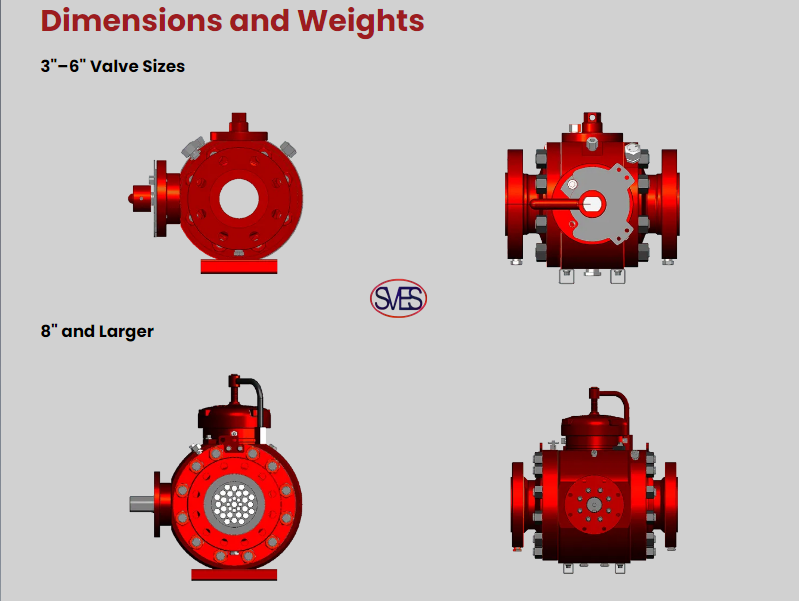

3.3 Size range: 2”-16”

3.4 Pressure Classes: ANSI Classes 150 to 1500

3.5 Standard temperature range: -20 to 300 deg. Fahrenheit

3.6 Special Order range: -50 to 400 deg. Fahrenheit

3.7 Materials: LF2, 316 SS, and Exotic Alloys as required

3.8 Seals: HSN, HNBR, James Walker, Viton, Teflon, Devlon Peek or as required

4. Application scenarios

The petroleum pipeline pigging Valve is suitable for the following scenarios:

4.1 Petroleum pipeline cleaning: the cleaning medium such as high-pressure water, chemicals, etc., can be introduced into the pipeline through the pigging Valve for cleaning.

4.2 Petroleum pipeline maintenance: during the pipeline maintenance process, the maintenance material such as lubricating oil, sealant, etc., can be introduced into the pipeline through the pigging Valve.

4.3 Petroleum pipeline renovation: during the pipeline renovation process, the new pipeline can be connected to the existing pipeline through the pigging Valve.

5. Benefits:

5.1 Trunnion Block design offers reduced torque and robustness

5.2 Complete Range of Fluid flexibility and compatibility

5.3 Cost savings over conventional pigging systems and skids

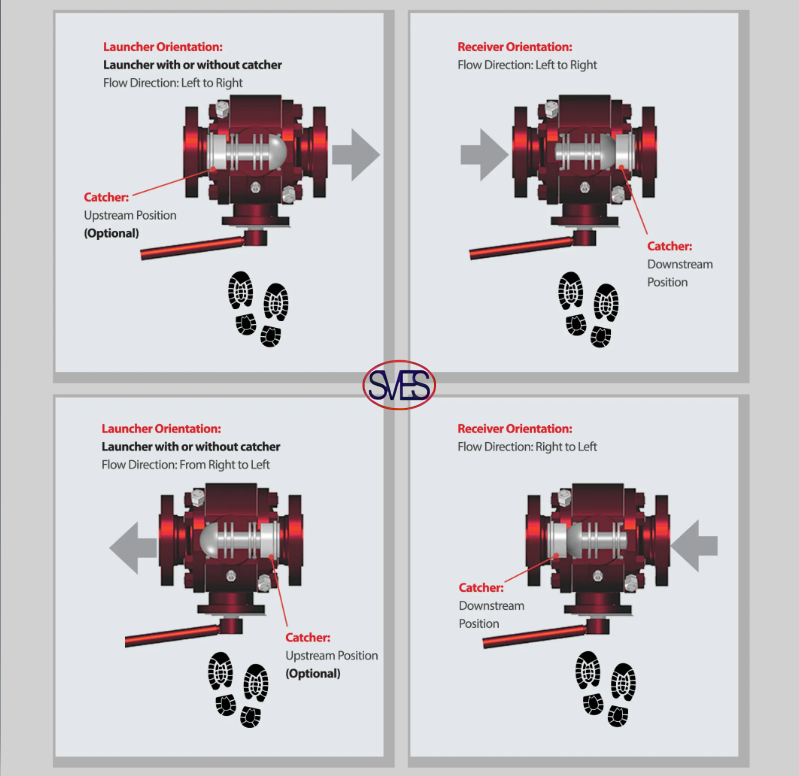

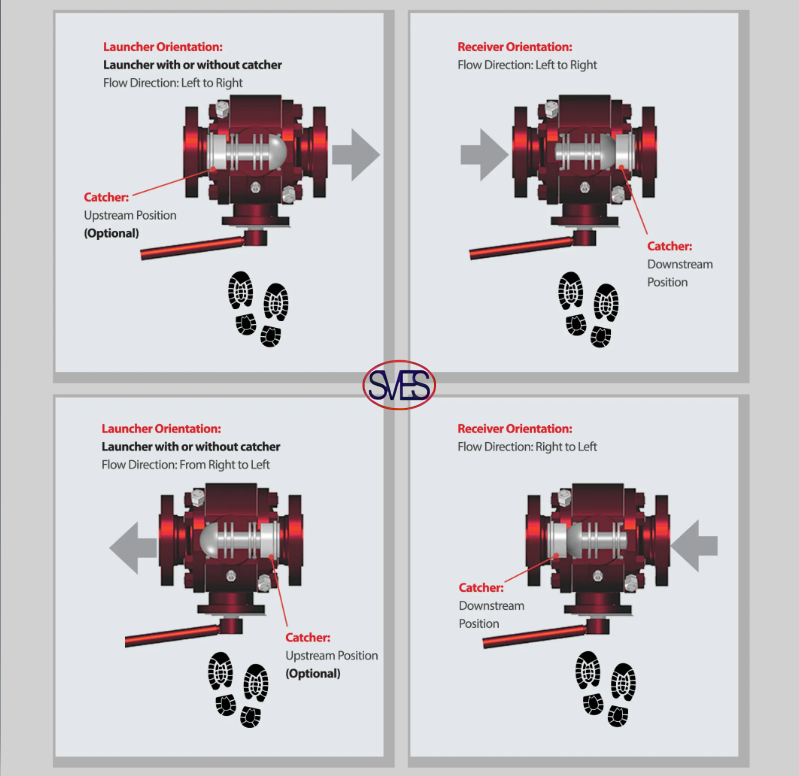

5.4 Available as a Launcher, Receiver, or Catcher.

5.5 Forged construction reduces NDE requirements

Pipeline pigging Valve

1. Specification

The petroleum pipeline pigging Valve is a special valve used for cleaning petroleum pipelines. It has the following characteristics:

1.1 Reliable sealing performance to prevent oil leakage during the cleaning process.

1.2 High corrosion resistance to withstand the corrosive medium in the petroleum pipeline.

1.3Simple structure, easy to maintain and operate.

2. Designed Engineered, manufactured and tested to API 6D

2.1 Industry Standards: API 6D, ASME B16.34 and API 598

2.2 Meets NACE MR0175-03

2.3 Positive Shut Off

2.4 Trunnion Block mounted Ball for reduced torque and stem loading

2.5 Large Bearings for smooth robust operation

2.6 Up Stream sealing with automatic downstream cavity relief

2.7 Double Block and Bleed with vent and drain capabilities

2.8 Large button head grease fittings with buried checks

2.9 Emergency seat sealant injection

2.10 Pig Entry Cap with vent

2.11 Pig Entry Cap with hex drive and spanner drive options

2.12 Open and Closed lockable stop plates 2”- 6”

2.13 6” and larger utilize a body cavity equalization valve

2.14 Large Actuator Mounting Pads and Stems

2.15 Accepts Bullet, Spherical, and Double-Dish pigs

2.16 Suitable pigs are fabricated to fit all SVES pig valves.

3. Parameter specifications

The parameter specifications of the petroleum pipeline pigging Valve include the following aspects:

3.1 Valve model: different models are available for selection based on the pipe diameter and pressure level.

3.2 Valve material: usually made of corrosion-resistant stainless steel or alloy material.

3.3 Size range: 2”-16”

3.4 Pressure Classes: ANSI Classes 150 to 1500

3.5 Standard temperature range: -20 to 300 deg. Fahrenheit

3.6 Special Order range: -50 to 400 deg. Fahrenheit

3.7 Materials: LF2, 316 SS, and Exotic Alloys as required

3.8 Seals: HSN, HNBR, James Walker, Viton, Teflon, Devlon Peek or as required

4. Application scenarios

The petroleum pipeline pigging Valve is suitable for the following scenarios:

4.1 Petroleum pipeline cleaning: the cleaning medium such as high-pressure water, chemicals, etc., can be introduced into the pipeline through the pigging Valve for cleaning.

4.2 Petroleum pipeline maintenance: during the pipeline maintenance process, the maintenance material such as lubricating oil, sealant, etc., can be introduced into the pipeline through the pigging Valve.

4.3 Petroleum pipeline renovation: during the pipeline renovation process, the new pipeline can be connected to the existing pipeline through the pigging Valve.

5. Benefits:

5.1 Trunnion Block design offers reduced torque and robustness

5.2 Complete Range of Fluid flexibility and compatibility

5.3 Cost savings over conventional pigging systems and skids

5.4 Available as a Launcher, Receiver, or Catcher.

5.5 Forged construction reduces NDE requirements