Classification Of Petroleum Machinery And Maintenance Precautions

2024-08-19 10:00Classification Of Petroleum Machinery And Maintenance Precautions

Petroleum machinery basically covers the mechanical equipment used in the entire process of oil exploration, oil drilling, oil production, and oil transportation.

Heat treatment technology of petroleum machinery The development of heat treatment technology of petroleum machinery basically represents the development process of heat treatment technology in the process of machinery manufacturing.

Let's take a look at the classification of petroleum machinery first:

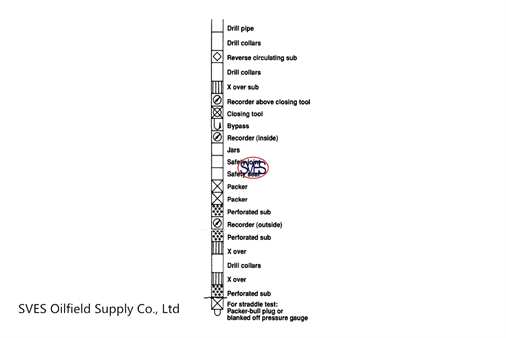

The categories of heat-treated parts in petroleum machinery products can be divided into: oil drill bits, drilling gears, rotary table gears, drill pipe tool joints, drilling winches, drilling chains, mud pump partsMud Pump Parts, drilling tools include elevatorsElevators, lifting clamps, lifting rings, box tap, milling shoe, oil tubing pumps, sucker rodsSucker Rods, perforating guns, drill stem testing toolsDrill Stem Testing Tools, engineering vehicles,Vehicle gearboxes, well headWell Head equipment parts, etc.

The equipment conditions of heat treatment of petroleum machinery are mainly electric heating cycle furnaces, continuous furnaces and conventional box furnaces, high-power trolley furnaces, deep well furnaces, vacuum heat treatment furnaces, ion nitriding furnaces, carburizing and carbonitriding furnaces, high-power high-frequency and medium-frequency induction heating equipment and high, medium and low temperature salt bath furnaces. At present, these heat treatment equipment are in good operating condition and meet the different heat treatment technical requirements of various workpieces.

How should machinery be maintained?

(1) Clean the inside and outside of the petroleum machinery. There is no oil stain on the sliding surfaces, screws, racks, oil holes, etc., and there is no oil leakage or air leakage in all parts. The chips, debris and dirt around the petroleum machinery should be cleaned up;

(2) Good lubrication. Refuel or change oil on time, keep oiling, no dry friction, normal oil pressure, bright oil mark, unobstructed oil path, oil quality meets the requirements, oil gun, oil cup, and oil felt are clean;

(3) Safety. Comply with safety operating procedures, do not overload the petroleum machinery, the safety protection devices of the petroleum machinery are complete and reliable, and unsafe factors are eliminated in time.

Daily maintenance of petroleum machinery is the basic work of petroleum machinery maintenance, which must be institutionalized and standardized. For the regular maintenance of petroleum machinery, work quotas and material consumption quotas must be formulated, and assessments must be conducted according to the quotas. Regular maintenance of petroleum machinery should be included in the assessment content of the workshop contract responsibility system. Regular inspection of petroleum machinery is a planned preventive inspection. In addition to human senses, the inspection means must also have certain inspection tools and instruments. It is carried out according to the regular inspection card. Regular inspection is also called regular inspection. Mechanical petroleum machinery should also be inspected for accuracy to determine the actual accuracy of the petroleum machinery.