Knowledge of drilling equipment--Drilling fluid solid control system and tools 3

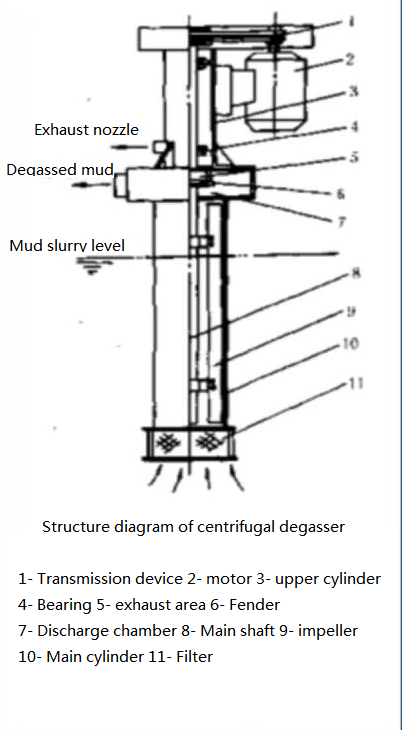

2024-01-30 10:00Degasser working principle

The degasser is used to remove the gas in the gas intrusion drilling fluid, ensure that the performance of the drilling fluid is relatively stable, and ensure that the cyclone can work normally.

There are two main types of degassers: atmospheric pressure type and vacuum type. The atmospheric pressure degasser uses a centrifuge to suction gas to infiltrate the mud, and with the help of centrifugal force, the slurry is sprayed in its spray tank and hits the inner wall, so that the gas is released. Vacuum degasser utilizes the suction effect of vacuum pudrilling fluidmp, forms negative pressure in the vacuum tank, drilling fluid enters the hollow shaft through the suction pipe under the action of atmospheric pressure, and then by the umbrella assembly around the hollow shaft, throws to the tank wall in the form of a jet, in the role of collision, vacuum and bubble separator, the bubble immersed in the drilling fluid is broken, and the gas escapes. It is pumped out by a vacuum pump and discharged to a safe place.

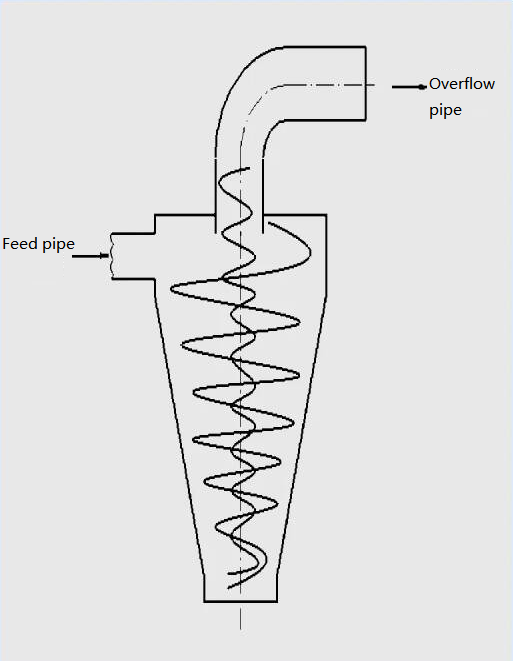

Schematic diagram of the structure of the desander and desilter

The sand and sludge removal device is composed of a set of hydrocyclones and a small ultra-fine mesh vibrating screen that treats the underflow of the cyclone and recovers the drilling fluid. After the liquid flow enters tangentially from the inlet, due to the effect of centrifugal force, the particles with large density are thrown to the outer wall, spirally flow down to the bottom flow port along the inner wall of the cyclone, and the liquid with small density flows out of the overflow port through the vortex conduit in the reverse spiral, the larger the nominal size of the cyclone, the coarser the solid particles removed, the smaller the working pressure required, and the greater the processing capacity of drilling fluid. The particle size of the separated solid particles of different diameters of cyclones is not the same. The solid-phase particle separation particle size of the desander is 44~74μm, so the 300mm cyclone can meet the design requirements. The particle size of the solid phase particle separation of the sludge remover is 8~44 μm, so the 100mm cyclone can meet the design requirements.

Selection of desander and desilting device

When selecting desander and desilter, the maximum displacement of the drilling pump must be referred to, in order to achieve a reasonable match. Whether it is a desander or a desilter, it is necessary to ensure that it can fully handle the maximum drilling fluid discharge during the drilling process. The drilling fluid treatment of desander and desilter is as follows

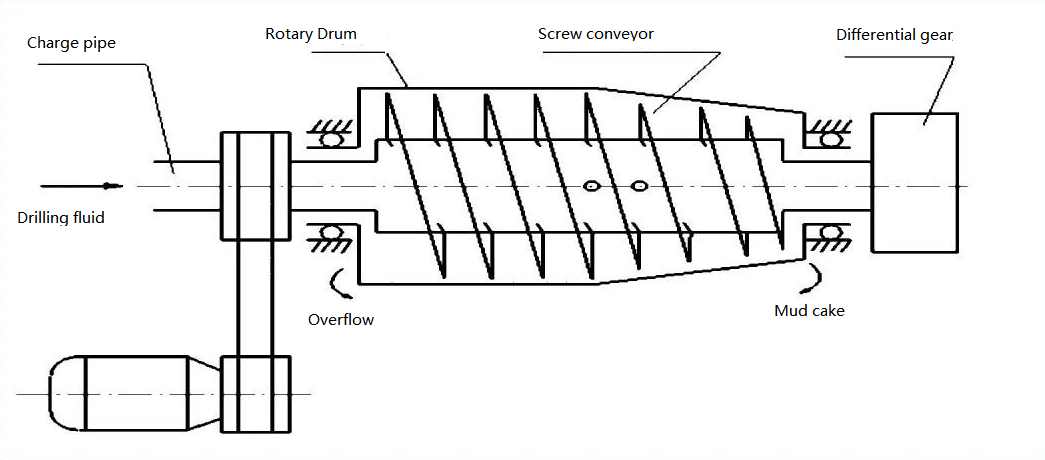

Schematic diagram of the structure of a centrifuge

The drilling fluid enters the hollow shaft in the auger from the feeding pipe and then flows into the bowl. Because the drum is rotating at high speed, the incoming drilling fluid is driven to rotate together, and the solid phase in the drilling fluid is thrown onto the drum wall, which is discharged by the screw output device to the discharge hole at the small end, and the clean drilling fluid is discharged from the overflow port at the large end of the drum as overflow

Centrifuge selection

The choice of centrifuge is affected by the particle size of the solid particles to be separated, the diameter of the drum of the centrifuge, the maximum speed and the separation factor, and the sedimentation centrifuge commonly used in the drilling site is based on the solid-liquid density difference, which is mainly used to remove 2-10μm solid phase substances in the drilling fluid, and is the last stage of drilling fluid solid control equipment.

Solid control auxiliary equipment