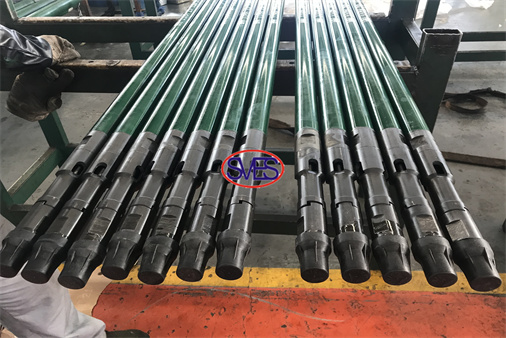

SVES Rod Pump delivered to oversea client

2024-01-25 10:00SVES Rod Pump delivered to oversea client

Sucker RodSucker Rod PumpOil Field Sucker RodOil Well Rod Pump

The Rod Pump type pump is also known as the insertion pump, wherein the fixed cylinder type top fixed rod type pump is characterized by a working barrel with two internal and external rod type pump, and the upper end of the outer working barrel is equipped with a vertebral base and a circlip (the position of the circlip is the depth of the pump), and the outer working barrel is first lowered into the well with the oil pipe when the pump is pumped. Then the inner working barrel equipped with a bushing and a piston is connected to the lower end of the rod into the outer working barrel and fixed by the circlip. In addition, there is a fixed point at the bottom of the pump barrel, and the piston is fixed at the bottom, and the pump barrel is driven by the rod to move up and down the pump barrel.

When checking the pump, it is not necessary to lift the flowline, but to pull out the inner working barrel through the sucker rod. The rod pump is convenient to check the pump, but the structure is complex and the manufacturing cost is high. The pump diameter allowed under the same pipe diameter is small, and it is suitable for the oil Wells with larger pump depth and smaller output.

After the rod pump is assembled on the ground, it is connected to the lower end of the rod, and the whole is lowered into the well through the tubing. It is convenient for operation and suitable for deep well without lifting tubing when inspecting pump. Because the operation time is shortened and the number of shackles on the tubing is reduced, the service life of the tubing is extended. Rod type pump can be divided into mechanical type and leather bowl type according to the type of support assembly, according to the support position is divided into fixed cylinder type top fixed, fixed cylinder type bottom fixed and moving cylinder type bottom fixed three.

At present, the conventional pump has the disadvantages of high processing requirements, inconvenient manufacturing and easy wear of metal piston and bushing.

In the process of pump operation, the piston is the active part, the role is to change the working principle of the pump by changing the pressure pump force. The pump valve is a follower and only opens when the pressure under the valve ball is greater than the pressure above it, allowing the liquid to flow upward through the seat hole, otherwise the valve is closed to prevent the liquid from flowing downward.

Rod Pump already delivered to oversea client and they are satisfied with the cargo.