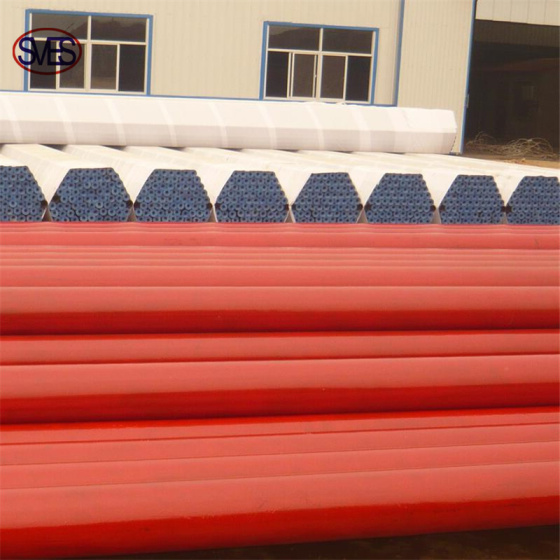

Aluminium Aloy Drill Pipe

With the development of technologies such as deep wells, ultra-deep wells, and air drilling, the requirements for the dynamic safety of drill strings are getting higher and higher. Aluminum alloy drill pipes have the advantages of light weight and low friction, and are widely used in the oil drilling industry. aspects:

1. The drilling capability for horizontal wells and horizontal sections is greatly enhanced;

2. Used in deep wells to reduce the load on drilling rigs and increase the drilling depth of existing drilling rigs;

3. Used in oil wells containing hydrogen sulfide corrosive media.

It is precisely because of these advantages that alloy drill pipes were successfully used in the SG-3 ultra-deep well on the Kola Peninsula.

The comprehensive cost savings of using aluminum alloy drill pipes is far greater than the purchase cost of higher gas output. Compared with steel drill pipes in applications, aluminum alloy drill pipes show better advantages:

1. The wet weight of aluminum alloy is reduced by 50%, and the weight of drill pipe is reduced by 30%, which improves the drilling capacity during mining;

2. Provides superior horizontal directional drilling performance, is more suitable for directional wells and large horizontal displacement wells, and reduces drag force;

3. Reduce 20%-30% of torque, resistance, smaller hydraulic loss, and significantly reduce mining costs;

4. Aluminum alloy can effectively prevent hydrogen sulfide and carbon dioxide corrosion and improve operational safety performance;

5. Aluminum alloy is non-magnetic and does not wear easily, making the casing easier to operate.