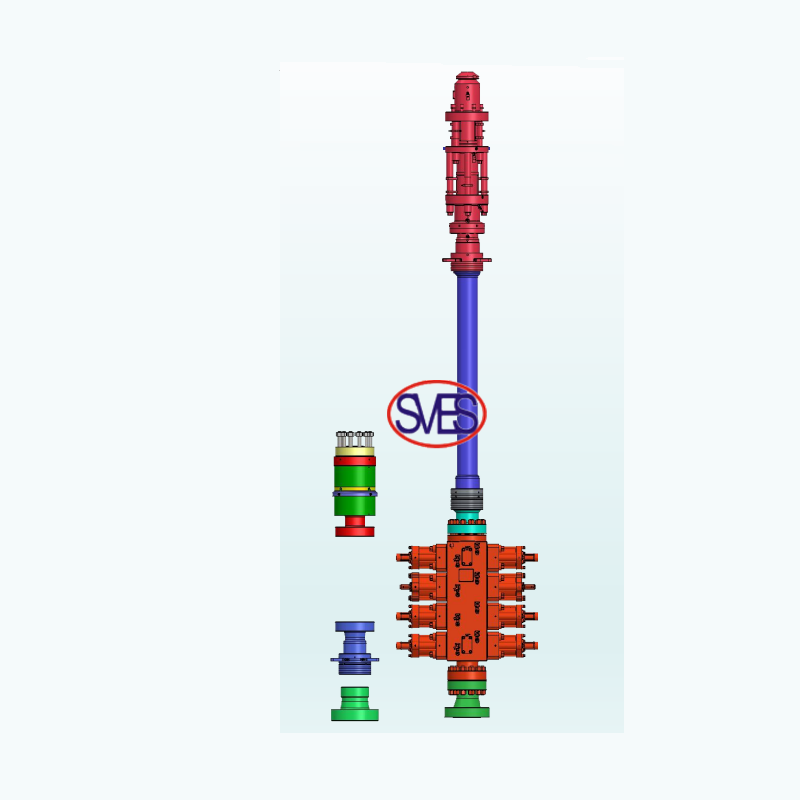

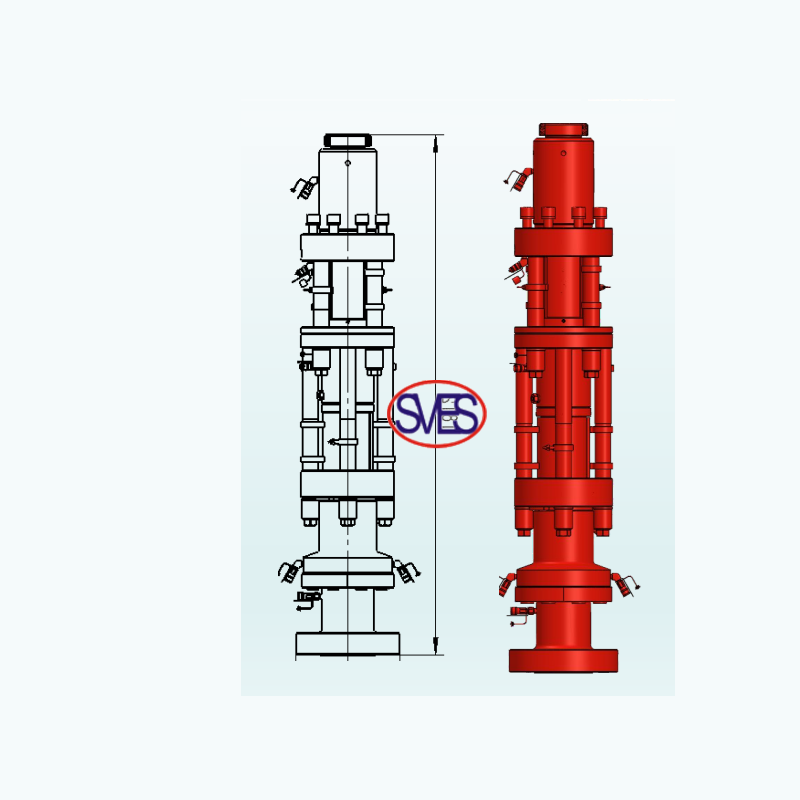

Coiled Tubing Blowout Preventer

Coiled Tubing Blowout Preventer Equipment

Name | Function | Configuration |

(Dual)Side Door Stripper Packer | Dynamic seal coiled tubing | Must |

Lubricator | Operating tools buffer zones | Must |

Upconversion Flange | Connect the lubricator to BOP | Must |

Quick Latch Equipment | Remote hydraulic connection | Optional |

Quad Ram BOP | Control wellhead pressure to prevent blowout accidents. There are four sets of rams: blind ram, shear ram, slip ram, pipe ram. |

Must |

Wellhead Adapter Flange | Connect the BOP to the wellhead | Optional |

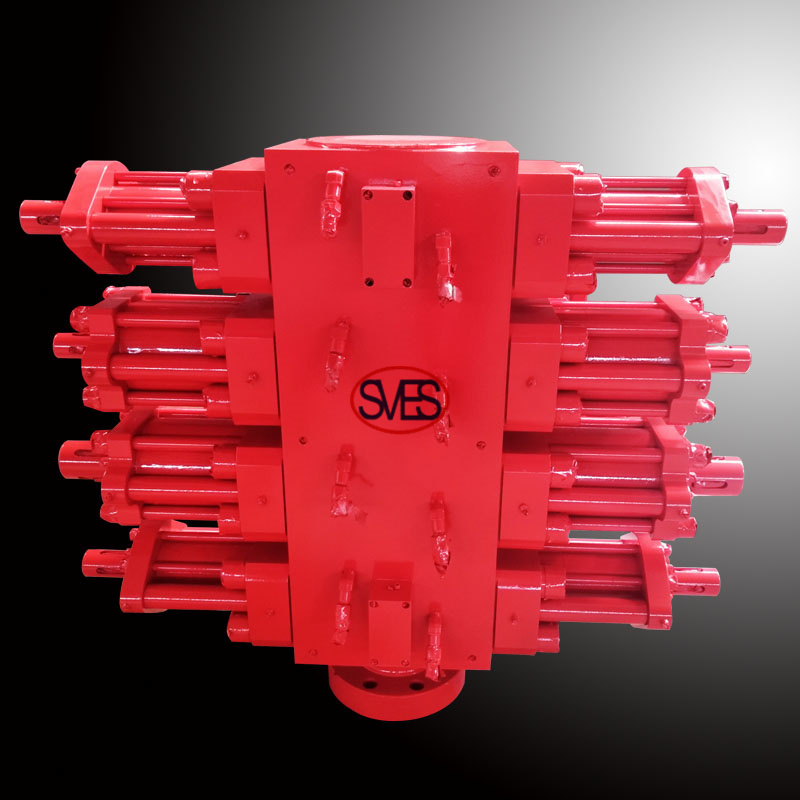

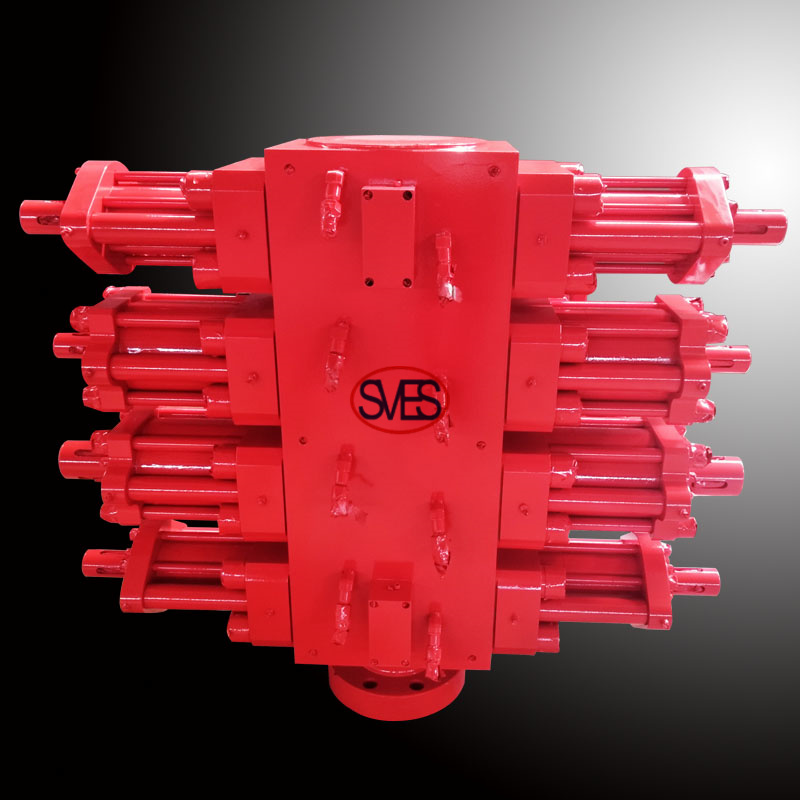

Hydraulic Quad Ram BOP

Functions:

It is a well control equipment in the process of coiled tubing operation. Its function is to quickly close the ram by hydraulic pressure to control wellhead pressure and prevent blowout.

Main functions:

Ø When there is no coiled tubing in the well, the well can be sealed with blind ram.

Ø When coiled tubing is operating in the well, abnormal well pressure and other special circumstances occur, and when the tubing needs to be cut, the tubing can be cut with shear ram, and at the same time, the well is sealed with blind ram, and the manifold connected by the side flange is pumped into the liquid kill well.

Ø When the coiled tubing is operating in a well, the tubing needs to be suspended, and the coiled tubing can be suspended with corresponding slips.

Ø When the coiled tubing is operating in the well, the well can be sealed with pipe ram of the corresponding specification.

The characteristic is that the whole device adopts the anti-hydrogen sulfide design; the opening and closing of ram are hydraulically driven and equipped with manual locking (The shearing ram is not equipped with manual locking).maintenance depends on hydraulic drive to disassemble the end cover and replace the ram accessories, which is convenient and quick.

Product Features: Anti-sulfur design, hydraulic removal of the end cover to replace the ram,low-torque end cover bolts, double-sealed balance valve, inner oil passage, ram stroke indication, manual locking.

Specification:

Size | ID | WP | Applicable Tubing | Upper and Lower Connection Manner | Working Temperature | Service Environment |

SV4FZ6-70 | 65 | 70 | 1″-1.5″ | 6BX 2.56″-10Kpsi/BX153 |

T-20(-29℃~ +121℃)Hydraulic oil select L-HM46/HV46

T-50(-46℃~ +80℃)Hydraulic oil select L-HS32 |

Crude oil, natural gas and water containing H2S(EE/HH) |

SV4FZ7-70 | 78 | 70 | 1″-2.0″ | 6BX 3.06″-10Kpsi/BX154 | ||

SV4FZ10-70 | 103 | 70 | 1″-2.375″ | 6BX 4.06″-10Kpsi/BX155 | ||

SV4FZ10-105 | 103 | 105 | 6BX 4.06″-15Kpsi/BX155 | |||

SV4FZ13-70 | 130 | 70 | 6BX 5.12″-10Kpsi/BX169 | |||

SV4FZ13-105 | 130 | 105 | 1.5″-2.875″ | 6BX 5.12″-15Kpsi/BX169 | ||

SV4FZ13-140 | 130 | 140 | 6BX 5.12″-20Kpsi/BX169 | |||

SV4FZ18-70 | 180 | 70 | 1.5″-3.5 ″ | 6BX 7.06″-10Kpsi/BX156 | ||

| SV4FZ18-105 | 180 | 105 | 6BX 7.06″-15Kpsi/BX156 |

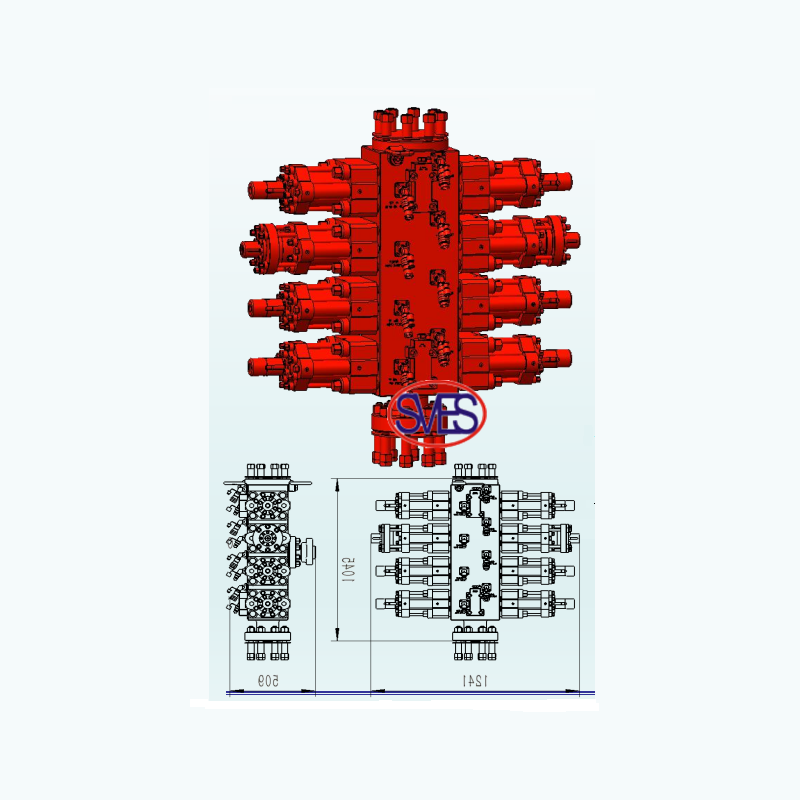

3.06″-10000psi Quad Ram BOP

Technical Parameter

Size:4FZ7-70

Applicable Tubing:1.0’’-2.0’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:6BX 3.06”-10K Studded Flange

Lower Connection:6BX 3.06”-10K Integral Flange

Blind Sealed Hydraulic Cylinder Open/Close Volume:1.04L/1.04L

Shear Hydraulic Cylinder Open/Close Volume:1.04L/1.55L

Suspension Hydraulic Cylinder Open/Close Volume:1.04L/1.04L

Semi-sealed Hydraulic Cylinder Open/Close Volume:1.04L/1.04L

Total Weight :1100kg

4.06″-10000psi Quad Ram BOP

Technical Parameter

Size:4FZ10-70

Sealing Tubing:1.0’’-2 3/8’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:6BX 4.06’’-10K Studded Flange

Lower Connection:6BX 4.06’’-10K Integral Flange

Blind Sealed Hydraulic Cylinder Open/Close Volume:1.9L/2.0L

Shear Hydraulic Cylinder Open/Close Volume:1.9L/3.2L

Suspension Hydraulic Cylinder Open/Close Volume:1.9L/2.0L

Semi-sealed Hydraulic Cylinder Open/Close Volume:1.9L/2.0L

Total Weight :1710kg

4.06″-15000psi Quad Ram BOP

Technical Parameter

Size:4FZ10-105

Sealing Tubing:1.0’’-2 3/8’’

Working Pressure:105MPa

Strength Test Pressure:158MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:6BX 4.06’’-15K Studded Flange

Lower Connection:6BX 4.06’’-15K Integral Flange

Blind Sealed Hydraulic Cylinder Open/Close Volume:2.9L/2.8L

Shear Hydraulic Cylinder Open/Close Volume:2.9L/4.3L

Suspension Hydraulic Cylinder Open/Close Volume:2.9L/2.8L

Semi-sealed Hydraulic Cylinder Open/Close Volume:2.9L/2.8L

Total Weight :2270kg

5.12″-10000psi Quad Ram BOP

Technical Parameter

Size:4FZ13-70

Sealing Tubing:1.0’’-2 7/8’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:6BX 5.12’’-10K Studded Flange

Lower Connection:6BX 5.12’’-10K Integral Flange

Blind Sealed Hydraulic Cylinder Open/Close Volume:3.0L/3.2L

Shear Hydraulic Cylinder Open/Close Volume:5.6L/5.7L

Suspension Hydraulic Cylinder Open/Close Volume:3.0L/3.2L

Semi-sealed Hydraulic Cylinder Open/Close Volume:3.0L/3.2L

Total Weight :2820kg

5.12″-15000psi Quad Ram BOP

Technical Parameter

Size:4FZ13-105

Sealing Tubing:1.0’’-2 7/8’’

Working Pressure:105MPa

Strength Test Pressure:158MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:6BX 5.12’’-15K Studded Flange

Lower Connection:6BX 5.12’’-15K Integral Flange

Blind Sealed Hydraulic Cylinder Open/Close Volume:4.2L/3.9L

Shear Hydraulic Cylinder Open/Close Volume:4.2L/6.3L

Suspension Hydraulic Cylinder Open/Close Volume:4.2L/3.9L

Semi-sealed Hydraulic Cylinder Open/Close Volume:4.2L/3.9L

Total Weight :3150kg

Size |

WP | Applicable Tubing | Upper and Lower Connection Manner |

Working Temperature | Service Environment |

SVFPH6-70 |

35 |

1″~1.5″ |

CB24 | T-20(-29℃~+121℃)Hydraulic oil selectL-HM46/HV46 |

Crude oil, natural gas and water containing H2S(EE/HH) |

SVFPH7-70 | 70 |

1″~2.0″ | CB34 | ||

SV4FZ7-105 | 70 | 6BX 3.06″-10Kpsi/BX154 | |||

SVFPH10-70 | 70 | 1.5″~2.875″ | CB44 | ||

SVFPH10-105 | 105 | 6BX 4.06″-15Kpsi/BX155 | T-50(-46℃~+80℃)Hydraulic oil selectL-HS32 | ||

SVFPH13-70 | 70 | CB54 | |||

SV2FPH13-105 | 105 | CB56 | |||

SV2FPH13-105 | 105 | 6BX 5.12″-15Kpsi/BX169 |

3.06″-10000psi Side Door Stripper Packer

Technical Parameter

Size:FPH7-70

Sealing Tubing:1.0’’-2.0’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M20×φ235

Lower Connection:CB34.B

Upper Hydraulic Cylinder Open Volume:0.8L

Upper Hydraulic Cylinder Close Volume:2.4L

Lower Hydraulic Cylinder Open Volume:0.2L

Lower Hydraulic Cylinder Close Volume:0.2L

Total Weight :205kg

3.06″-15000psi Side Door Stripper Packer

Technical Parameter

Size:FPH7-105

Sealing Tubing:1.0’’-2.0’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ260.35

Lower Connection:6BX 3.06”-15K Flange

Side Door Open/Close Volume: 0.5L /2.5L

Piston Open/Close Volume: 0.3L /0.3L

Total Weight :303kg

4.06″-10000psi Side Door Stripper Packer

Technical Parameter

Size:FPH10-70

Sealing Tubing:1.5”-2 7/8”

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ330

Lower Connection:CB44.B

Side Door Open/Close Volume: 1.6L /5.2L

Piston Open/Close Volume: 0.6L /0.6L

Total Weight :438kg

4.06″-15000psi Side Door Stripper Packer

Technical Parameter

Size:FPH10-105

Sealing Tubing:1.5’’-2 7/8’’

Working Pressure:70MPa

Strength Test Pressure:105MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ330

Lower Connection:6BX 4.06’’-15K Flange

Side Door Open/Close Volume: 1.6L /5.4L

Piston Open/Close Volume: 0.6L /0.6L

Total Weight :615kg

3.06″-15000psi Dual Side Door Stripper Packer

Technical Parameter

Size:2FPH10-105

Sealing Tubing:1.0”-2.0”

Working Pressure:103.5MPa

Strength Test Pressure:155MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ260.35

Lower Connection:6BX 4.06”-15K Integral Flange

Upper Side Door Open/Close Volume:0.5L /2.5L

Upper Piston Open/Close Volume:0.3L /0.3L

Lower Side Door Open/Close Volume:0.5L /2.5L

Lower Piston Open/Close Volume: 0.3L /0.3L

Total Weight :580kg

4.06″-15000psi Dual Side Door Stripper Packer

Technical Parameter

Size:2FPH13-105

Sealing Tubing:1.5”-2 7/8”

Working Pressure:103.5MPa

Strength Test Pressure:155MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ330

Lower Connection:6BX 5.12”-15K Flange

Upper Side Door Open/Close Volume:1.6L /5.4L

Upper Piston Open/Close Volume:0.6L /0.6L

Lower Side Door Open/Close Volume:1.6L /5.4L

Lower Piston Open/Close Volume: 0.6L /0.6L

Total Weight: 1040kg

4.06″-15000psi Dual Side Door Stripper Packer

Technical Parameter

Size:2FPH13-105

Sealing Tubing:1.5”-2 7/8”

Working Pressure:103.5MPa

Strength Test Pressure:155MPa

Maximum Hydraulic Pressure:21MPa

Upper Connection:8-M30×φ330

Lower Connection:CB56

Upper Side Door Open/Close Volume:1.6L /5.4L

Upper Piston Open/Close Volume:0.6L /0.6L

Lower Side Door Open/Close Volume:1.6L /5.4L

Lower Piston Open/Close Volume: 0.6L /0.6L

Total Weight: 1025kg

4.06″-15000psi Inner Dual Door Stripper Packer

Technical Parameter

Size:2FPH13-105

Sealing Tubing:1.5’’-2 7/8’’

Working Pressure:103.5MPa

Strength Test Pressure:155MPa

Maximum Hydraulic Pressure:35MPa

Upper Connection:8-M30×φ330

Lower Connection:CB56

Upper Piston Open/Close Volume:0.5L /0.5L

Lower Side Door Open/Close Volume:1.6L /5.3L

Lower Piston Open/Close Volume: 0.5L /0.5L

Total Weight :784kg

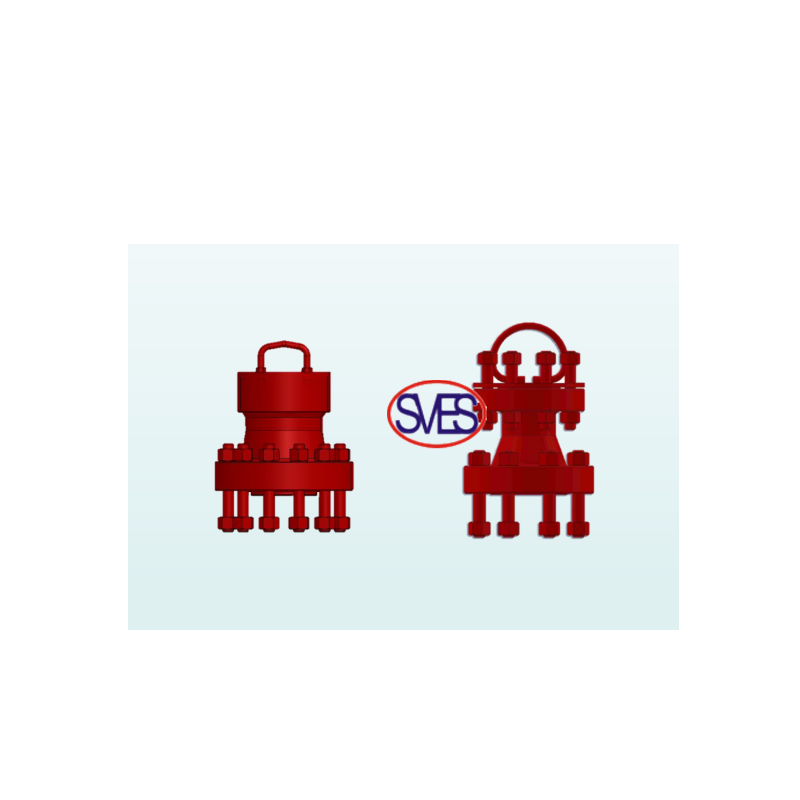

Quick Latch Equipment is installed on the upper end of the blowout preventer, and the injection head and lubricator are hoisted by a crane to connect with the quick latch equipment, and it is hydraulically locked.

Size | ID | WP | Upper Connection | Lower Connection |

SVCBQ7-70 | 78 | 70 | CB34 | 6BX 3.06″-10Kpsi |

SVCBQ10-70 | 103 | 70 | CB44 | 6BX 4.06″-10Kpsi |

SVCBQ10-105 | 103 | 105 | CB46 | 6BX 4.06″-15Kpsi |

SVCBQ13-70 | 130 | 70 | CB54 | 6BX 5.12″-10Kpsi |

SVCBQ13-105 | 130 | 105 | CB56 | 6BX 5.12″-15Kpsi |

SVCBQ18-70 | 180 | 70 | CB74 | 6BX 7.06″-10Kpsi |

SVCBQ18-105 | 180 | 105 | CB76 | 6BX 7.06″-15Kpsi |

The lubricator can be used in multiple connections, the top end is connected tothe stuffing box, and the bottom end is connected to the blowout preventer.The total connection length of the lubricator is greater than the total length of the downhole tool string, and the lubricator can be used to accommodate the running tool string.

Size | ID | WP | Length | Length | Clasp Type |

SVFPG6-70 | 65 | 70MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CQ24 |

SVFPG7-70 | 78 | 70MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CB34 |

SVFPG10-70 | 103 | 70MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CB44 |

SVFPG10-105 | 103 | 103.5MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CB46 |

SVFPG13-70 | 130 | 70MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CB54 |

SVFPG13-105 | 130 | 103.5MPa | 0.5m、1m、1.5m、2m、2.5m | 2ft、4ft、8ft | CB56 |

The wellhead adapter flange is connected to the lower end of the quad ram blowout preventer, which is used to connect the whole set of blowout preventer to the wellhead; or to connect the blowout preventer with different clasp types or flanges.

Size | ID | WP | Upper Connection | Lower Connection |

SVFL6-70×7-70 | 65 | 70MPa | 6BX 2.56-10K | 6BX 3 .06-10K |

SVFL7-70×10-70 | 78 | 70MPa | 6BX 3 .06-10K | 6BX 4 .06-10K |

SVFL10-70×13-70 | 103 | 70MPa | 6BX 4 .06-10K | 6BX 5.12-10K |

SVFL6-70×CQ24.P | 65 | 70MPa | CQ24.P | 6BX 2.56-10K |

SVFL7-70×CB34.P | 78 | 70MPa | CB34.P | 6BX 3 .06-10K |

SVFL10-70×CB44.P | 103 | 70MPa | CB44.P | 6BX 4 .06-10K |

SVFL13-70×CB54.P | 130 | 70MPa | CB54.P | 6BX 5.12-10K |

SVFL13-105×CB56.P | 130 | 105MPa | CB56.P | 6BX 5.12-15K |