- Home

- >

- Products

- >

- Liner Hanger

- >

Liner Hanger

SVDYX-A Hydraulic Liner Hanger (Single Cone and Single Row Slips Structure)

Liner Hanger Hydraulic , designed with single/double cone and single/double row slips structure, is hydraulically set by applying pressure through the run-in string. After brass ball is dropped to ball at in landing collar, high pressure fluid acts on piston inside cylinder and move slips upward to set position.

DYX-A Liner Hanger, designed with single cone and single row slips structure, is hydraulically set by applying pressure through the run-in string. After brass ball is dropped to ball at in landing collar, high pressure fluid acts on piston inside cylinder and move slips upward to set position.

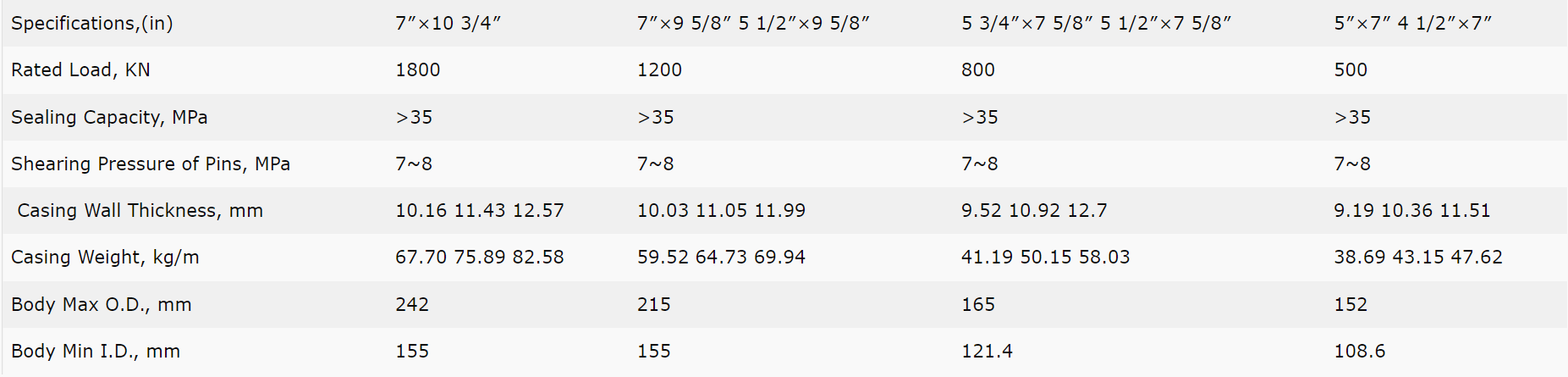

Technical Specification:

Features:

1.Working with ball-setting carrier, suitable for horizontal and highly-deviated wells.

2.Be set hydraulically suitable for shallow and medium-depth wells.

3.Retrievable pack-off bushing can be retrieved with setting tool, avoid drill-out.

4.Sealing element is made from nitrile/fluorine rubber, rating temperature 120 ℃ to 200 ℃

5.Setting tool can be easily released just by slacking off certain weight and using right hand rotation.

6.Main parts are made with high-strength alloy steel providing high burst/collapse resistance.

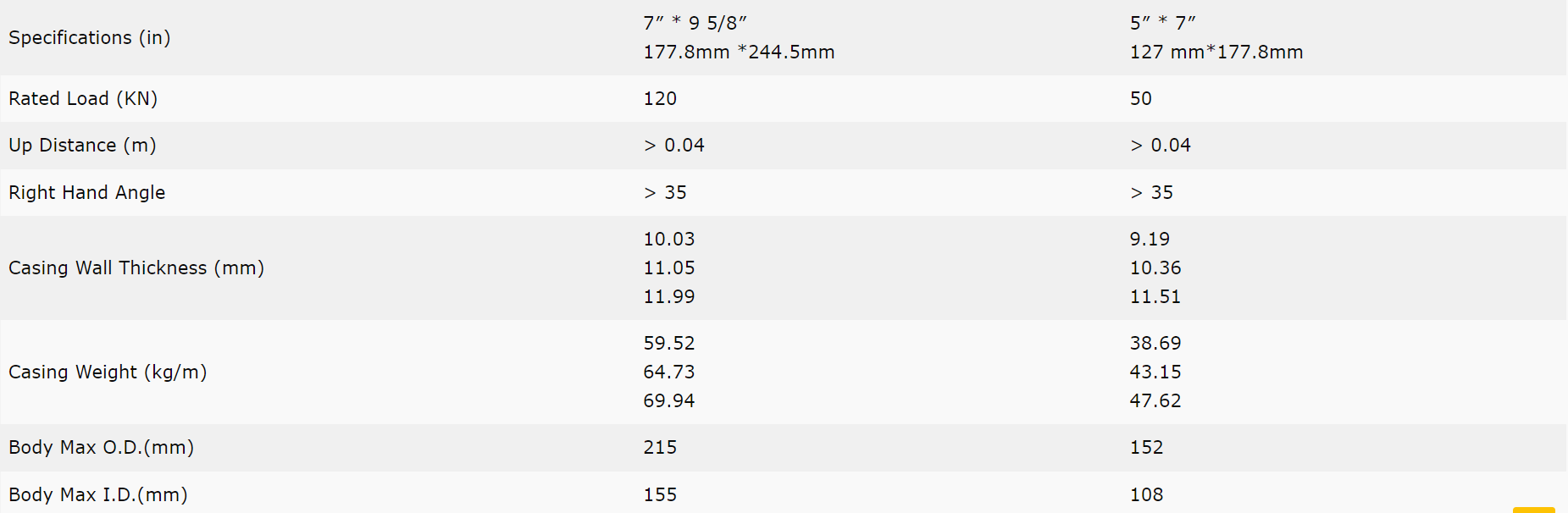

SVSYX-A Hydraulic Liner Hanger (Double Cone and Double Row Slips Structure

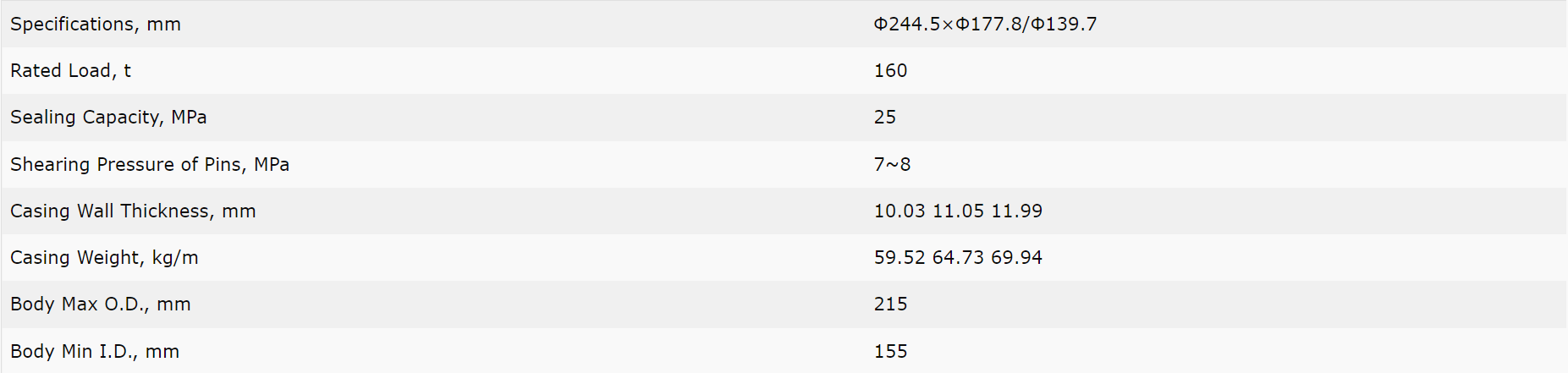

SYX-A Liner Hanger, designed with double cone and double row slips structure, is hydraulically set by applying pressure through the run-in string. After brass ball is dropped to ball seat in landing collar, high pressure fluid acts on piston inside cylinder and move slips upward to set position.

Technical Specification:

Features:

1.Working with ball-setting carrier, suitable for horizontal and highly-deviated wells.

2.Be set hydraulically suitable for shallow and medium-depth wells.

3.Retrievable pack-off bushing can be retrieved with setting tool, avoid drill-out.

4.Sealing element is made from nitrile/fluorine rubber, rating temperature 120 ℃ to 200 ℃

5.Setting tool can be easily released just by slacking off certain weight and using right hand rotation.

6.Main parts are made with high-strength alloy steel providing high burst/collapse resistance.

7.The dual-cone structure is suitable for hanging long heavy liner in deep wells. Liner weight is distributed onto the internal wall of the previous casing more evenly.

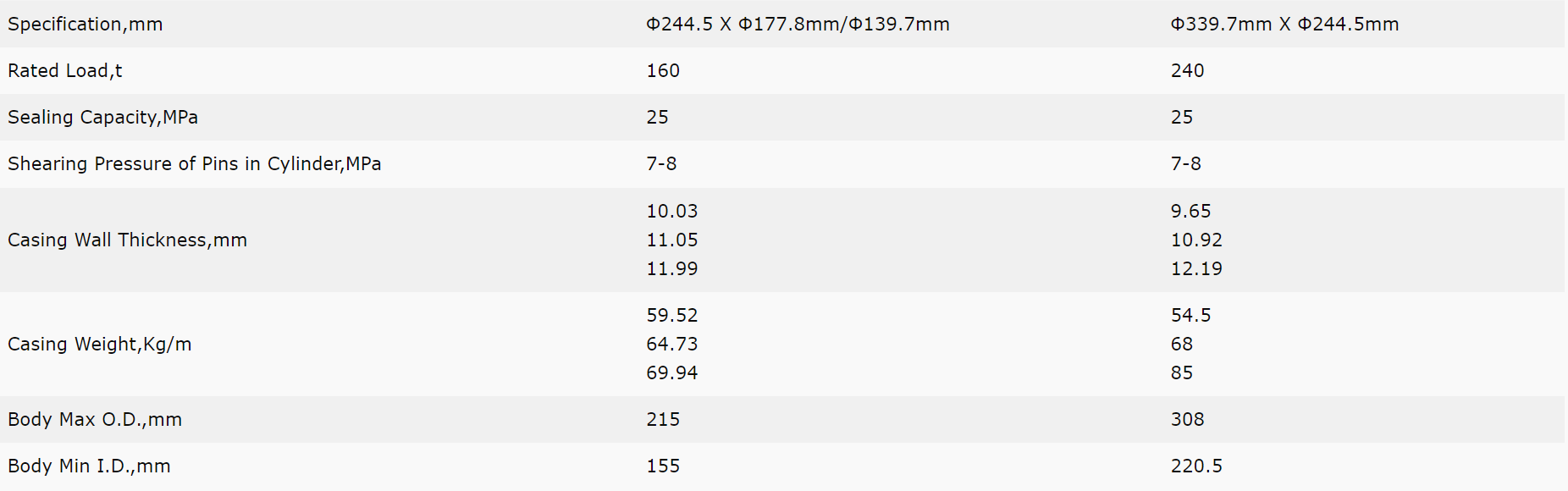

SVSSX-A Hydraulic Liner Hanger (Double Cone, Double Cylinder and Double Row Slips Structure)

Technical Specification:

Features:

1.Working with ball-setting carrier, suitable for horizontal and highly-deviated wells.

2.Be set hydraulically suitable for shallow and medium-depth wells.

3.Retrievable pack-off bushing can be retrieved with setting tool, avoid drill-out.

4.Sealing element is made from nitrile/fluorine rubber, rating temperature 120 ℃ to 200 ℃

5.Setting tool can be easily released just by slacking off certain weight and using right hand rotation.

6.Main parts are made with high-strength alloy steel providing high burst/collapse resistance.

7.The dual-cone structure is suitable for hanging long heavy liner in deep wells. Liner weight is distributed onto the internal wall of the previous casing more evenly.

XGS-A Hydraulic Liner Hanger(Single Cone and Single Row Slips Structure)

XGS-A Hydraulic liner Hanger is hydraulically set by applying pressure through the run-in string. A setting ball is circulated and dropped to ball seat built into the lauding collar. Applied pressure acts on the internal piston and moves ships up the cone to the set position.

Technical Specification:

Features:

1.Working with ball-setting carrier, suitable for horizontal and highly-deviated wells.

2.Be set hydraulically suitable for shallow and medium-depth wells.

3.Retrievable pack-off bushing can be retrieved with setting tool, avoid drill-out.

4.Sealing element is made from nitrile/fluorine rubber, rating temperature 120 ℃ to 200 ℃

5.Setting tool can be easily released just by slacking off certain weight and using right hand rotation.

6.Main parts are made with high-strength alloy steel providing high burst/collapse resistance.

7.The dual-cone structure is suitable for hanging long heavy liner in deep wells. Liner weight is distributed onto the internal wall of the previous casing more evenly.

SVSGJ-A Mechanical Liner Hanger (Single Cone and Single Row Slips Mechanical Structure)

It is a mechanical hanger with single cone and single slip. A “J” shaped groove was machined into the body. The hanging can be realized by lifting up and rotating down. The structure is simple, suitable for vertical wells and shallow wells.

The liner hanger can be set by picking up and lowering the drill string.

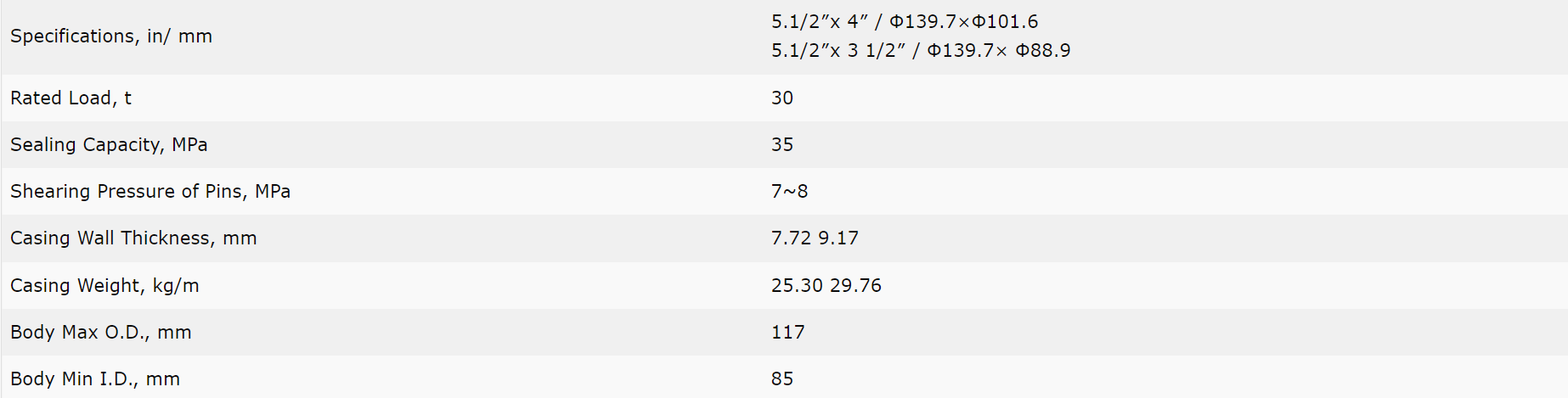

Technical Specification:

Features:

1. Large bypass channels in the cone increase annular flow area.

2. The J slot design prevent the hanger from prematirely setting during deployment.

3. Depending on the friction between bow spring and the wall of upper casing to set.

4. Set by right hand rotation.

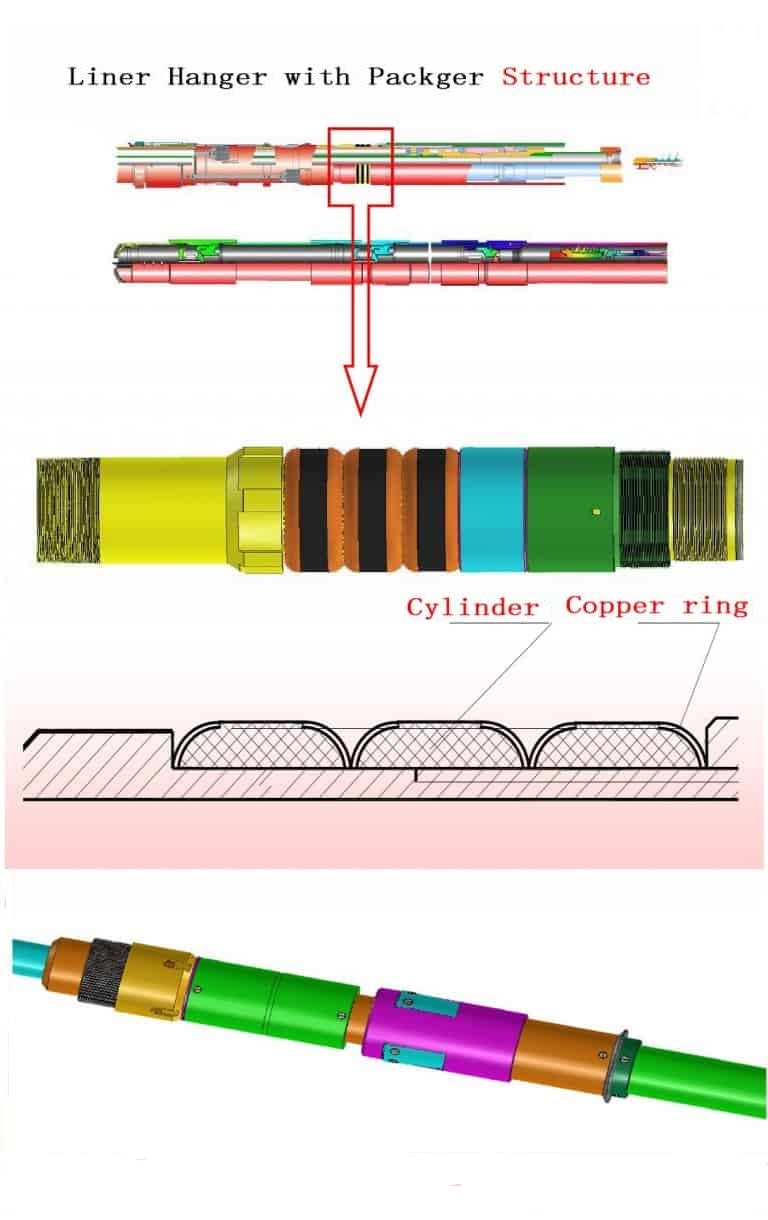

SVSGFG-A Liner Hanger with Packer ( Comprised Liner Hanger and Packer)

The liner hanger with packer could seal the annulus between liner and upper casing,and prevent the liquid and the gas from migration.After finishing cementing,set the packer,circulate the excess slurry, and don’t affect the formation under the liner hanger.

When run the liner to the designed depth,set the liner hanger,release the setting tools and finish cementing.After bumping the plug,pull the drill pipe,the claws On the setting tools expand out and act on the upper surface of the polished bore receptacle sleeve,lower down the drill pipe,shear the pins and the rubber sleeves expand to seal the annulus between upper casing and the poilished bore receptacle.

Features:

Design a self—locking rachet ring,set the packer easily and seal the annulus permanently.

Set the packer with 30-50T load.

Packer seal capability is 35MPa.

Rubber could work well under 120 ℃.

Rubber sleeve has good acid resistant, alkali-resistant and oil resistant properties as well as high temperature resistance.

Combination of free fall packer and liner hanger, the Liner Hanger with Packer performs double functions – sealing and liner hanging.

The sealed ram can be pulled out along with running tools, therefore no drill out is required.