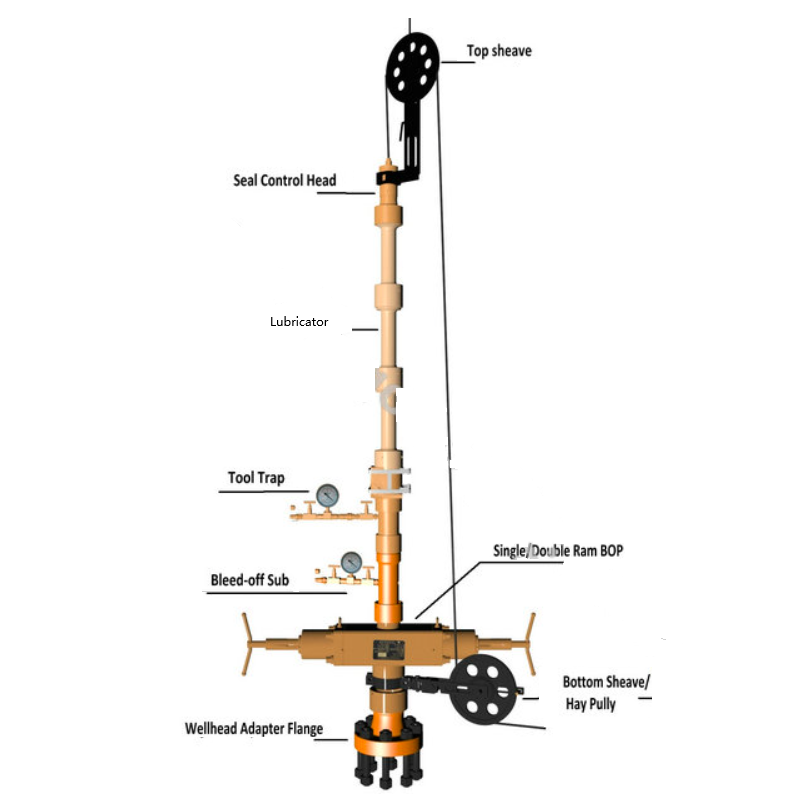

Slickline Pressure Control Equipment

Lightweight Wellhead Slickline Pressure Control Equipment

Slickline Pressure Control Equipment is used to flowing oil well, gas well, water injection well and coal seams well for wire logging with pressure or paraffin removal operation, could supply pressure buffer and transition zone for string tools. In operation, the wellhead can be sealed when wire is static and dynamic state with pressure, or closed in the course of overflow and other unforeseen circumstances beyond controlling, to prevent blowout accidents. Operation conveniently and safety reliable.

The PCE is mainly consists of Slickline sealing control head, tool catcher, lubricators, Tool Trap (includes of release assly with pressure), Blow Out Preventer, Top& Bottom Sheave, Pressure testing& releasing Assembly, Wellhead crossover flange (crossover sub), Lifting tool, Hydraulic Control Module,Pedal assemly, anti-freeze/ unfreeze and pressure self-checking system, Transport and Storage Frame Skid, Pressure test plugs etc.

The seal control head

Manual Slickline seal control head

Slickline Stuffing Box

Hydraulic Seal Head

Slickline Stuffing Box is designed to pack-off all size of solid wireline up to 0.125",with safety and convenience.

Slickline Stuffing Box consists of a chamber which contains packing with an external adjustable nut. The

Seal Control Head used for sealing the wellhead in time and promise safety of operation.

It can be controlled by manual as well as hydraulic. Replace the sealing elements can meet different sizes slickline to work.

Technical Parameters

Model | Working Pressure | Lower End of Lubricator ID (mm) | Lower End of Connection Manner (mm) | Wire ID (mm) | Working Environment |

SVFPT4-21 | 21 | 44(46) | Tr70X8 | ||

SVFPT6-21 | 21 | 62(65) | 4"-6SA | ||

SVFPY4-35 | 35 | 44(46) | Tr70X8 | ||

SVFPT6-70 | 70 | 62(65) | 4 3/4u-4ACME | 2.4mm 1.8mm 3.2mm | H2S/STD |

SVFPY7-35 | 35 | 76(78) | 5'-4 ACME | ||

SVFPT7-70 | 35 | 62(65) | 5 3/4MACME | ||

SVFPT10-70 | 70 | 102(103) | 8 3/4"-4ACME | ||

SVFPT6-105 | 105 | 62(65) | 5 3/4"-4ACME | ||

SVFPT7-105 | 70 | 76(78) | 5 3/4"-4ACME | ||

SVFPT10-105 | 105 | 102(103) | 91/2"-4ACME |

Product Features

--Compact structure and light weight.

2. Tool Catcher

Product Description

Hydraulic Tool Catcher is a safety device, which is installed between the seal head and the lubricator, it ismainly used for automatically grasping rope socket when tools are connected underground and are lifted to the top end of the lubricator, thereby effectively preventing cables from falling off the cable head or instruments drop in well when the cable is broken or the rope socket is impacted on the bottom end of the seal head because of the very fast pulling speed or over big pull force.

Hydraulic Tool Catcher,when release the rope socket , should use the hydraulic control system for pressurizing to lead the hydraulic force to push the piston in the tool catcher and the robotic gripper, the piston drives the robotic gripper which is opened, and then release the rope socket. The upper end connect the grease injection seal head choke flow tube directly,and the safety choke flow ball valve is designed on it, once the cable falling off or broken from the cable head accidentally, under the function of the high pressure flow or the airflow, the safety choke flow ball valve can plug the cable hole to choked flow and seal wellhead automatically.

Technical Parameters

Model | Working Pressure (Mpa) | Lower end of lubricator ID (mm) | Lower end of Connection Manner (mm) | Type of Control | Working Environment |

SVSBZ6-35 | 35 | 62(65) | 4 1/4"-6SA | Manual/Hydraulic | H2S/STD |

SVSBZ7-35 | 35 | 76(78) | 5"-6SA | ||

SVSBZ6-70 | 70 | 62(65) | 4 3/4"-4ACME | ||

SVSBZ7-70 | 70 | 76(78) | 5 3/4"-4ACME | ||

SVSBZ7-105 | 105 | 76(78) | 7"-5ACME | ||

SVSBZ10-35 | 35 | 103 | 7 "—5ACME | ||

SVSBZ10-70 | 70 | 103 | 8 3/8"-4ACME | ||

SVSBZ10-105 | 105 | 103 | 9 1/2"-4ACME |

1.Equipped with remote liquid control device to improve the safety of the device;

2.With self-disassembly function of nonnut,easy connection;

3.The pressure bearing part adopts high strength alloy steel,which has good corrosion resistance.

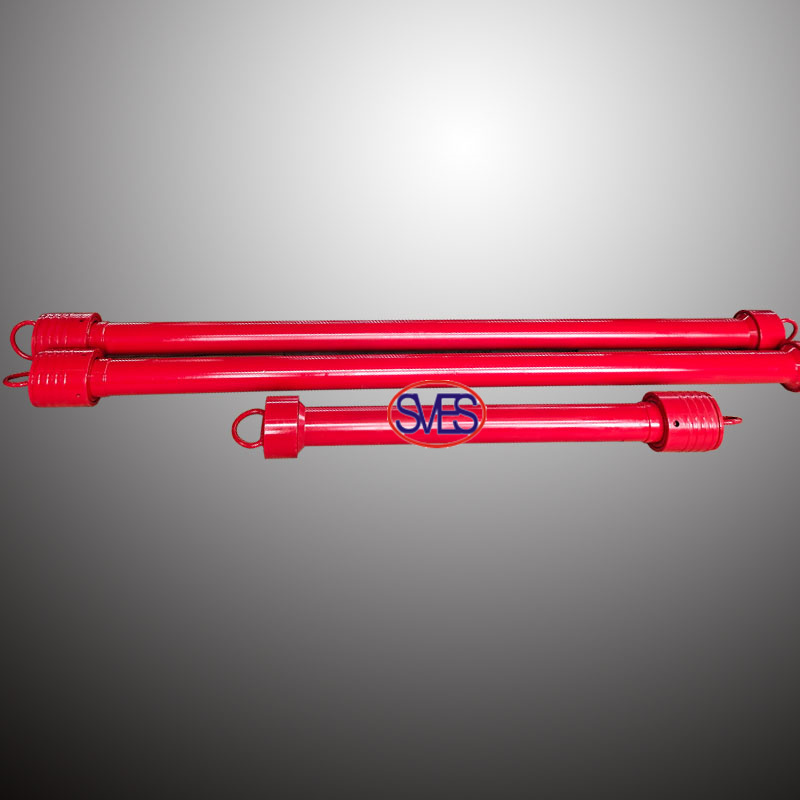

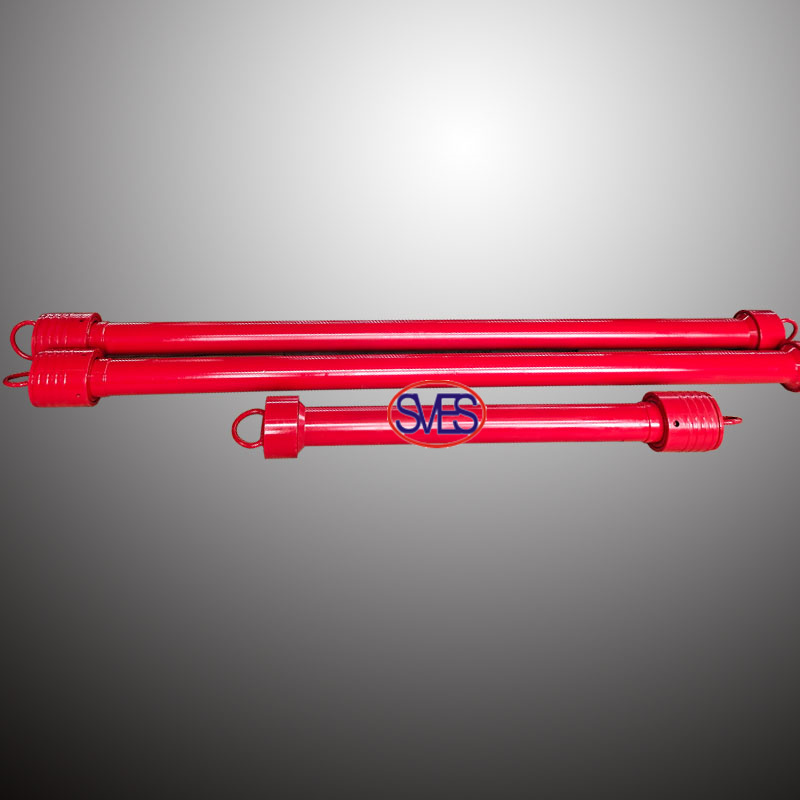

2. Lubricator

Product Description

The Lightweight Lubricators usually consists of four basic parts: a quick union collar, a male quick union, a lubricator tube, and a female quick union.

Model | Working Pressure (Psi) | ID (mm) | Cable Size (mm) | Connection | Service Environment | Working Temperature |

SVFPG6-35 | 5000 | 62(65) | ∮1.8-3.2 | 4 1/4"-6SA | Crude oil. Water, Natural gas with H2S and CO2 | T-20 (-29~ + 121 ℃ ( high temperature to 350 thermal recovery type optional) |

SVFPG7-35 | 5000 | 76(78) | 5"-4ACME | |||

SVFPG10-35 | 5000 | 103 | 7 3/4"-5ACME | |||

SVFPG6-70 | 10000 | 62(65) | 4 3/4'--4ACME | |||

SVFPG7-70 | 10000 | 76(78) | 5 3/4"-4ACME | |||

SVFPG10-70 | 10000 | 103 | 8 3/8n-4ACME | |||

SVFPG7-105 | 15000 | 76(78) | 7 3/4"-4ACME | |||

SVFPG10-105 | 15000 | 103 | 9 1/2n-4ACME | |||

SVFPG6-70T | 10000 | 62(65) | 4 3/4"-4ACME | |||

SVFPG7-70T | 10000 | 76(78) | 5 3/4"-4ACME | |||

SVFPG10-70T | 10000 | 103 | 8 3/8"-4ACME |

--The pressure bearing part adopts high strength alloy steel,which has good corrosion resistance;

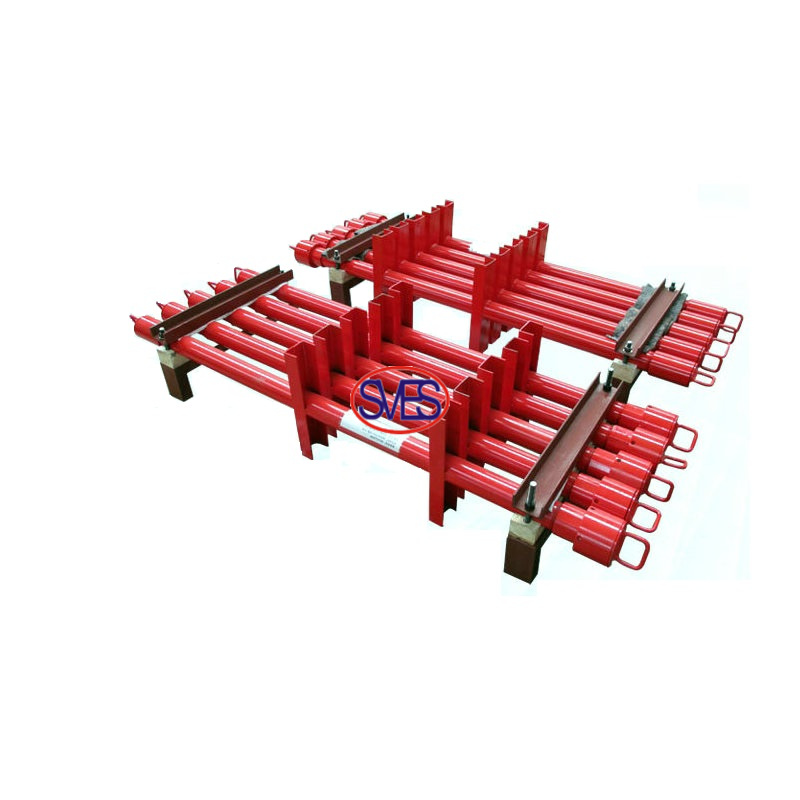

3. Top sheave

Bottom sheave

Pully

4. Tool trap

Technical Parameters

Model

| ID (mm) | Working Pressure (MPa) | Working Environment | Opeartion Manner

|

Connection Manner(Union) |

SVXBZ12-35 | 120 | 35 | H2S/STD | Manual | 7 3/4 " -4ACME |

SVYXBZ 12-70 | 120 | 70 | Manual | 9"-4ACME | |

SVYXBZ 12-105 | 120 | 105 | Manual | 1! I/8,”-4ACME | |

SVXBZ13-35 | 130 | 35 | Manual | 7 3/4" -4ACME | |

SVYXBZ 13-70 | 130 | 70 | Hydraulic | 9"-4ACME | |

SVYXBZ13-10 | 130 | 105 | Manual | 12 1/2"-4ACME | |

SVXBZ 14-35 | 140 | 35 | Hydraulic | 7 3/4 " -4 ACME | |

SVXBZ 14-70 | 14() | 70 | Hydraulic | Tr240 X611 s/~ S-4ACME | |

SVYXBZ 16-35 | 160 | 35 | Hydraulic | 9 1/2”-4 ACME | |

SVXBZ 18-35 | 180 | 35 | Manual | 9 5/8" -4 ACME | |

SVYXBZ 18-70 | 180 | 70 | Hydraulic | 11 5/8"-4 ACME |

NOTE : 1 .There are Bowen and Otis quick union for all threaded selective.

2.Additional size available on request.

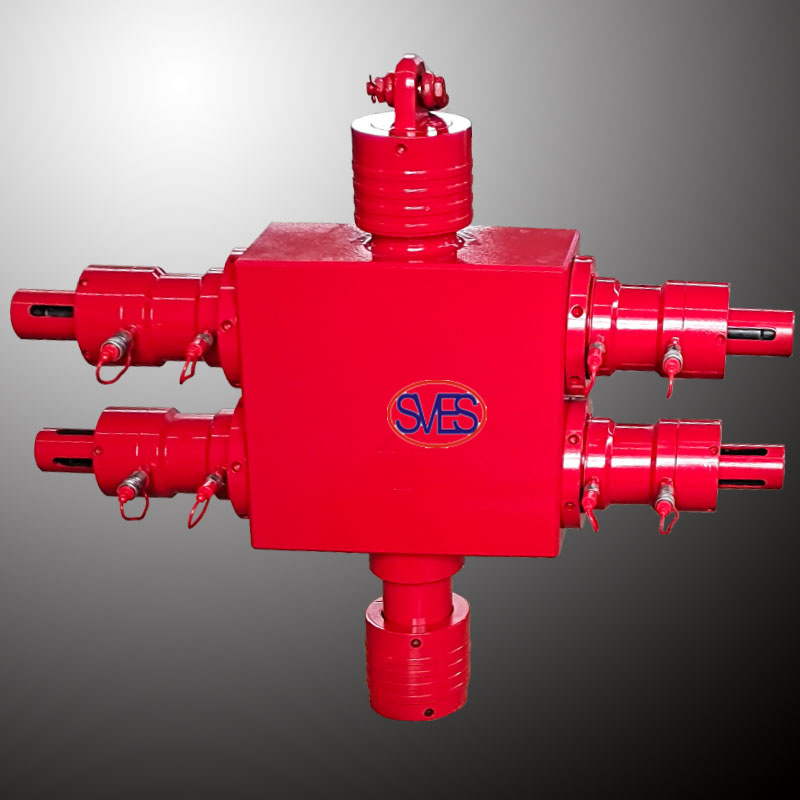

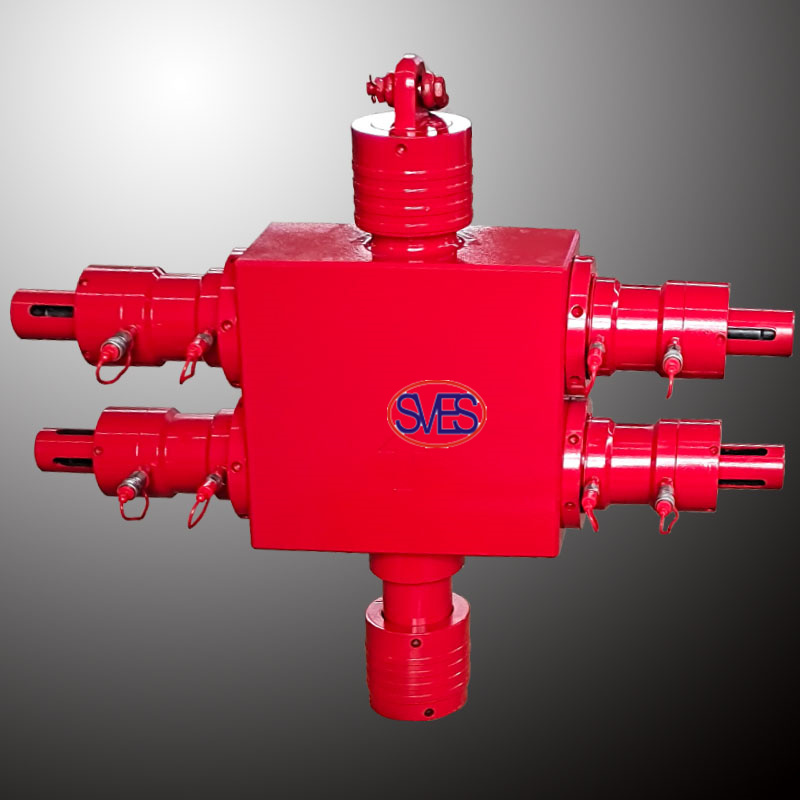

5. Slickline Ram Bop

Compact Slickline Valve

Manual Control Ram BOP

Hydaulic Control Ram BOP

The BOP is used for sealing the wellhead to prevent well blowout accidents in logging operation when there are accidents and there are cables in the well. The BOP has simple structure, convenient application and maintenance, small volume, light weight, high pressure bearing, hydraulic remote control and simple and reliable operation.

The BOP is mainly composed of main casing, and ram assembly piston, hydraulic cylinder, lead screw, end cap, hand wheel and other spare parts, which are moving in the main casing in opposite direction. When the well needs to be sealed, the hydraulic control and grease injection pressure control system is pressurized to push the piston, thereby leading the two ram bodies to move towards the center of the well bore, and well sealing can be achieved through the associative action of the front rubber sealing element and the top sealing rubber. The ram can be locked on the shut-in position through clockwise rotating the locking hand wheel. What be specially noticed is that before the well is opened, the locking hand wheel must be anticlockwise rotated, the hydraulic control system can be used for pressurizing after the hand wheel is totally receded to the initial position, the piston is hydraulically pushed to led the two rams to rearwards move, and then, the well can be opened. It should be guaranteed to open the full i.d. to prevent the instruments and the ram from colliding when the well is opened.

6.Crossover/ Wellhead Adapter

The main function of the crossover is that it can connect the wellhead with the whole Pressure Control Equipment conveniently and tightly。The thread type can be machined following the API-6A Standard or client's request.

7. 2 9/16”5000Psi Slickline Pressure Control Equipment String

2 9/16” 10000Psi Slickline Logging Pressure Control Equipment String

3”~3 1/16” 5000Psi Slickline Logging Pressure Control Equipment String

3”~3 1/16” 10000Psi Slickline Logging Pressure Control Equipment String

4“-4 1/16”5000Psi Slickline Logging Pressure Control Equipment String

4“-4 1/16”10000Psi Slickline Logging Pressure Control Equipment String