Blowout Preventer, Koomey Unit

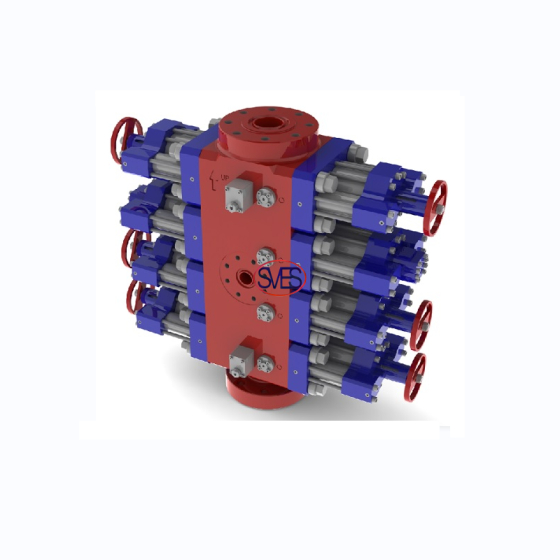

S Type Ram BOP

Structual Feature

● Pressurized components adopts superior alloy steel with good strength and impact toughness.

● Door seal of the high pressure BOP uses combined seal, which has better seal from the well pressure.

● Use floating or integral gate, can seal safely and change conveniently.

● Use buriel-type oil passage, Bearing hinge is separated from the hydraulic hinge.

● Hinge structure is simple, easy to dismount and mount.

● Use big arc-type shell on both sides of the chamber, and transit by arc-type all around, to reduce the peak stress of the shell under pressure.

● With compact structure, smaller than similar foreign products.

● The internal shell of BOP resistant to low temperature can process pipeline, to make the steam flow inside the BOP, radiat heat.

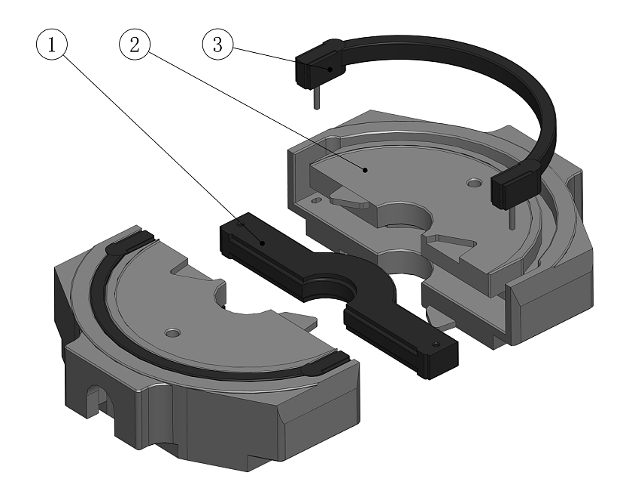

Ram Assembly

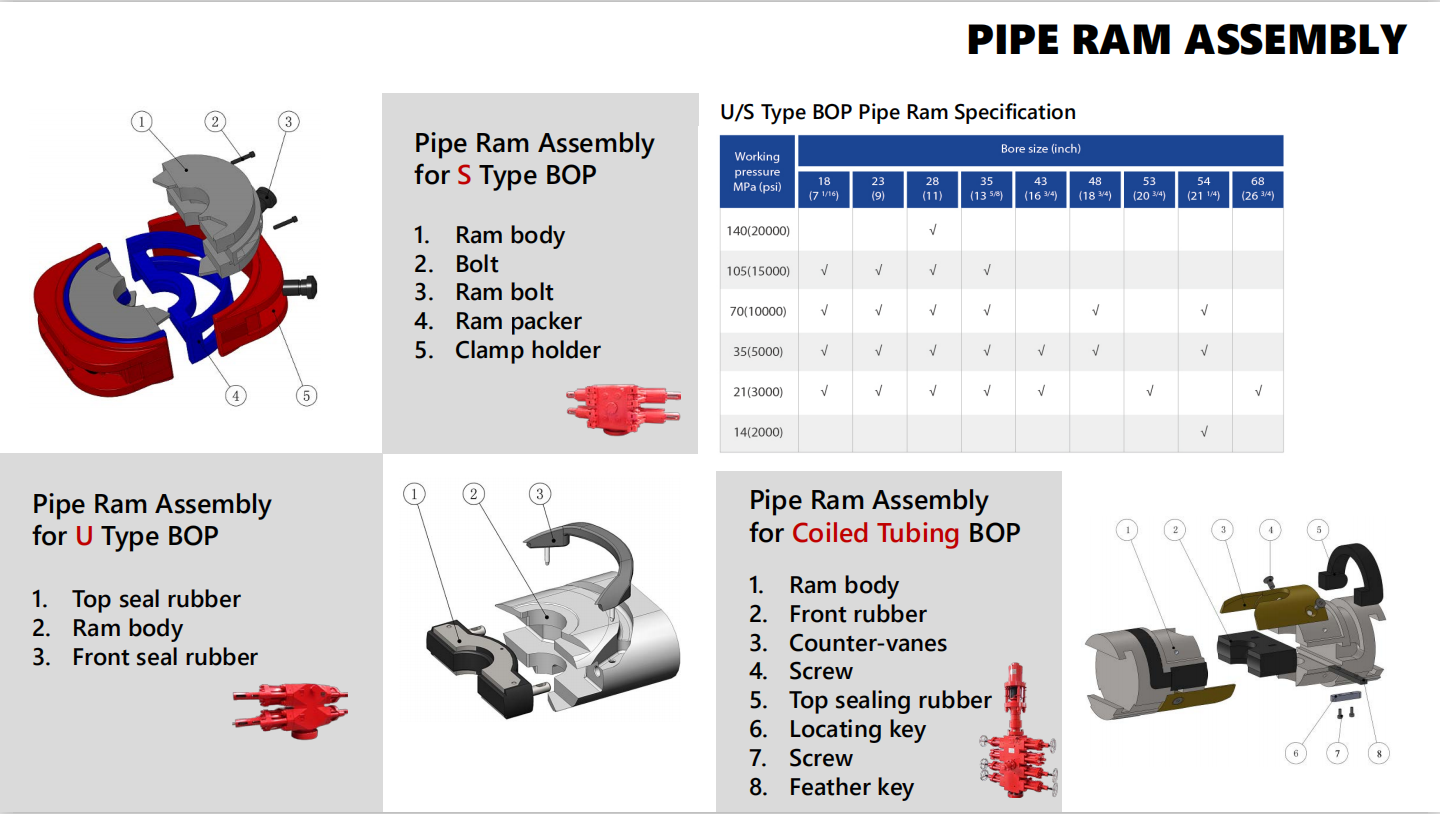

Pipe Ram

1. Top seal 2. Front seal 3. Ram body

HF type Ram assembl

1. Top seal rubber 2. Front seal rubber 3. Ram body

4. Clamp holder 5. Ram bolt

H type Ram assembly

1. Ram body 2. Bolt 3. Ram bolt 4. Ram rubber

5. Clamp holder

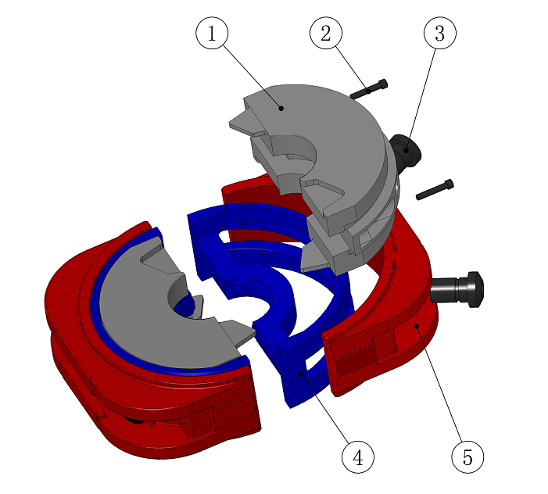

S type Ram assembly

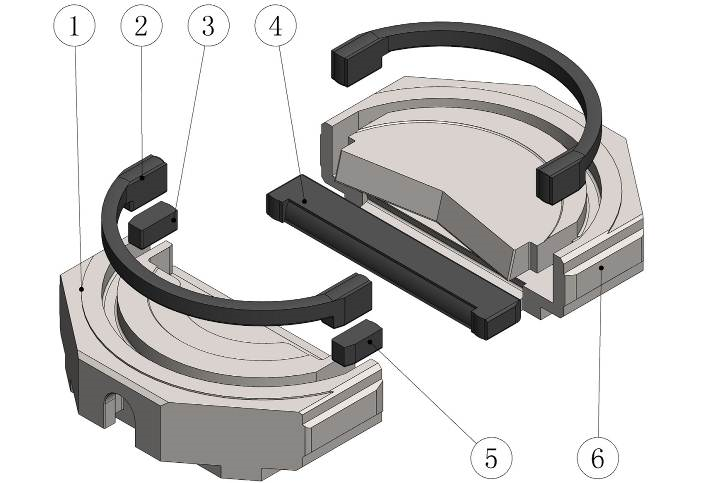

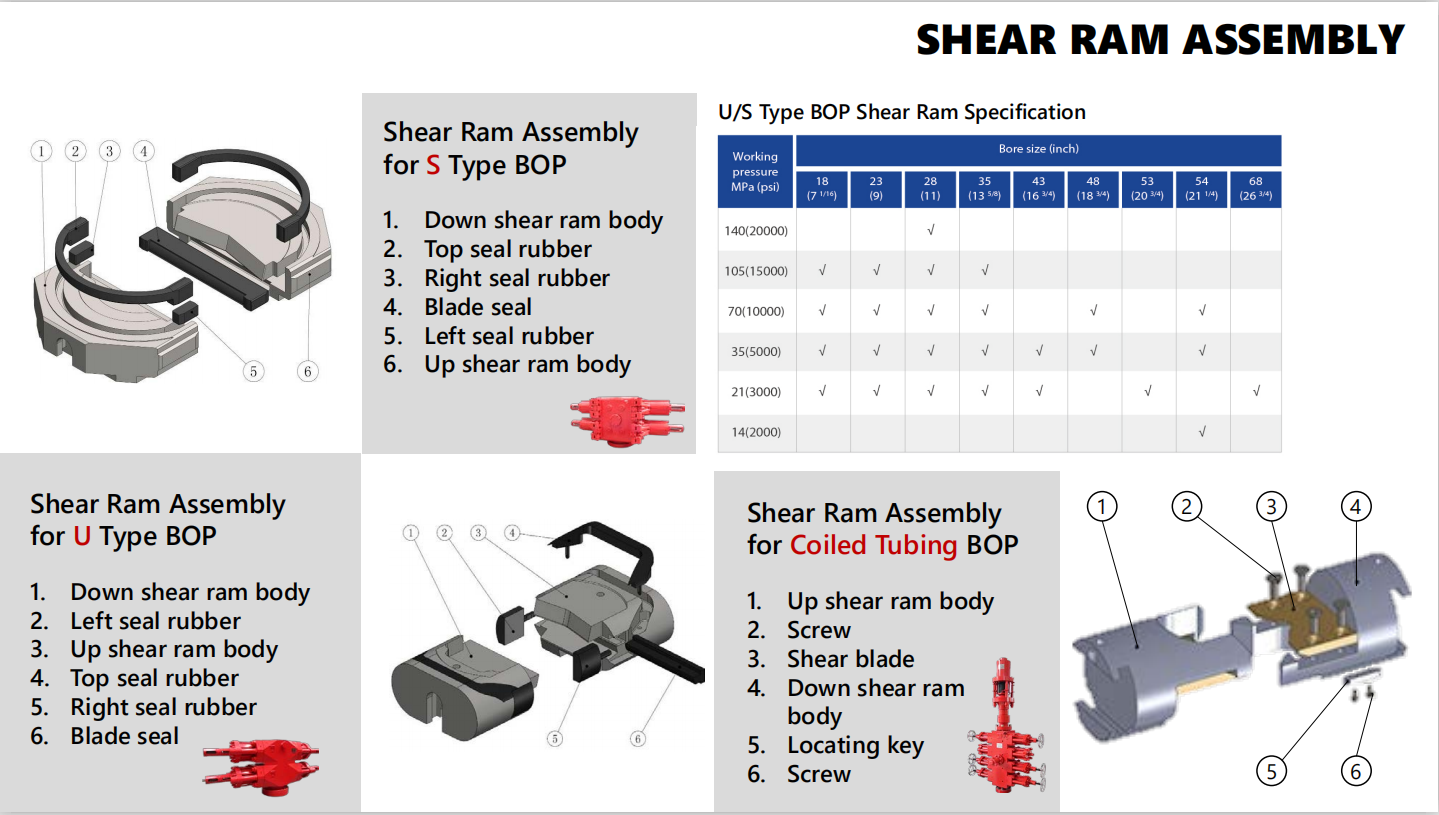

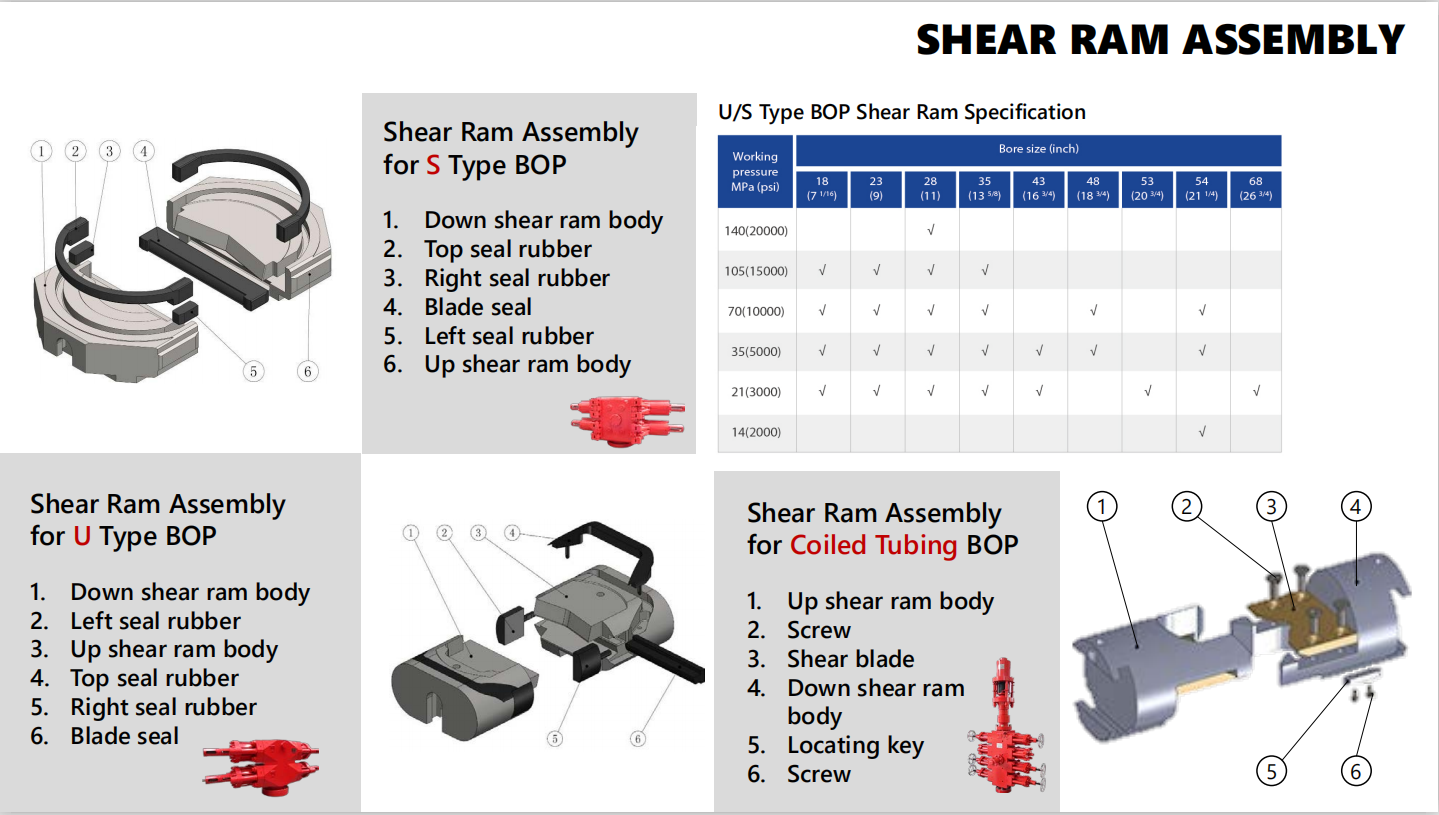

Shear Ram

Shear ram can cut pipe the well, blindly close the wellhead, and also used as blind ram when there is no pipe in the well. The installation of shear ram is the same with the original ram.

● In the normal condition used as blind ram, in case of emergency, used as shear ram.

● Shear damper can be repeatedly cut pipe and not damage the blade, The weared the blade can be reused after the repair. Shenkai produces the shear ram with shear life in more than five times, Allowed to replace the sealing rubber.

● The ordinary ram blade is integrated with the ram body.

● The ram blade of BOP resistant to high sulfer is separated with the ram body, which is easy to change blade after blade damaged, and make the ram body be able to repeated use.

● The contact sealing surface between top seal of shear ram and blade is large, which effectively reduce the pressure on the rubber sealing surface, and prolong its life.

1. Down shear ram body 2. Top seal rubber 3. Right seal rubber 4. Blade sealLeft seal rubber 3. Up shear ram body

4. Top seal rubber 5. Left seal rubber 6. Up shear ram body

Shear Ram Assembly Structure of S type Ram BOP

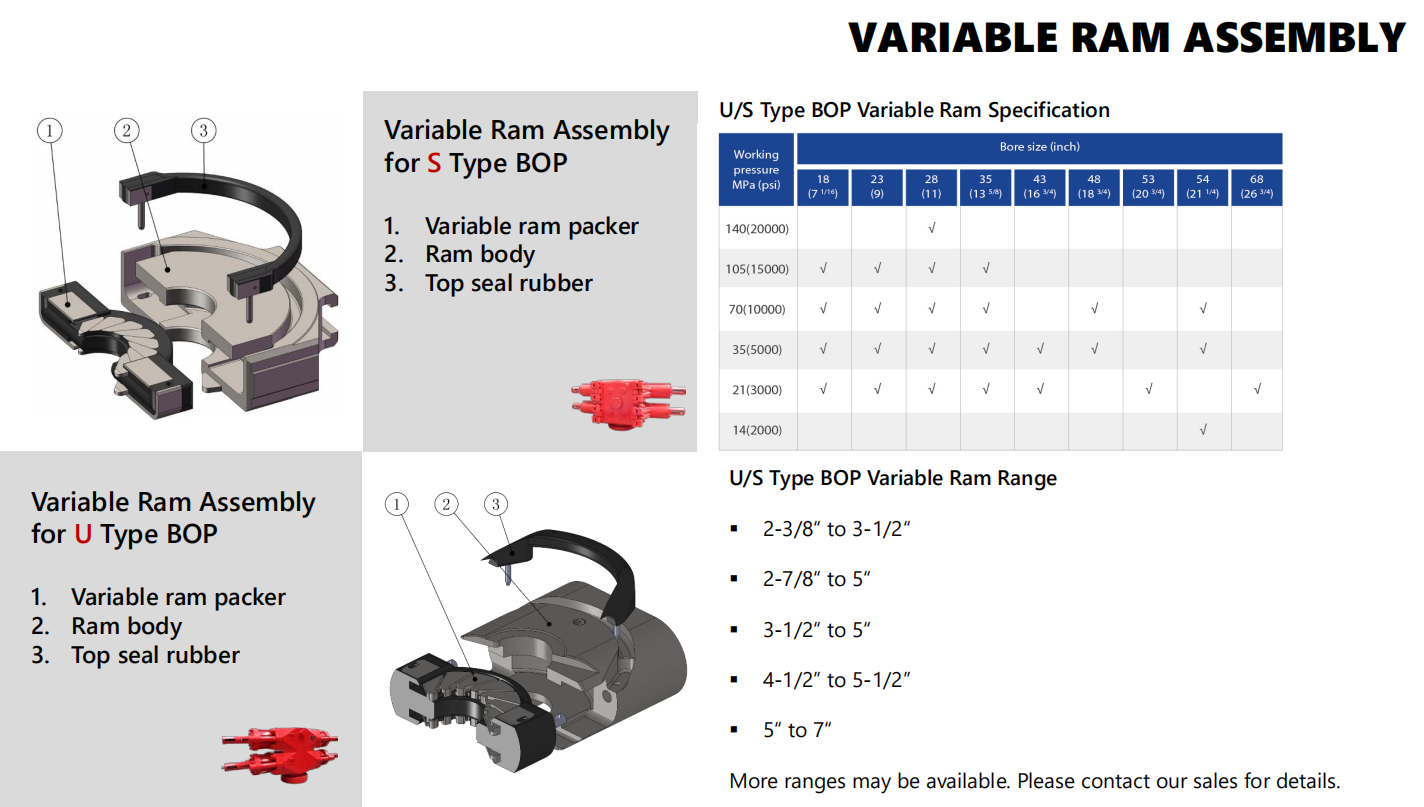

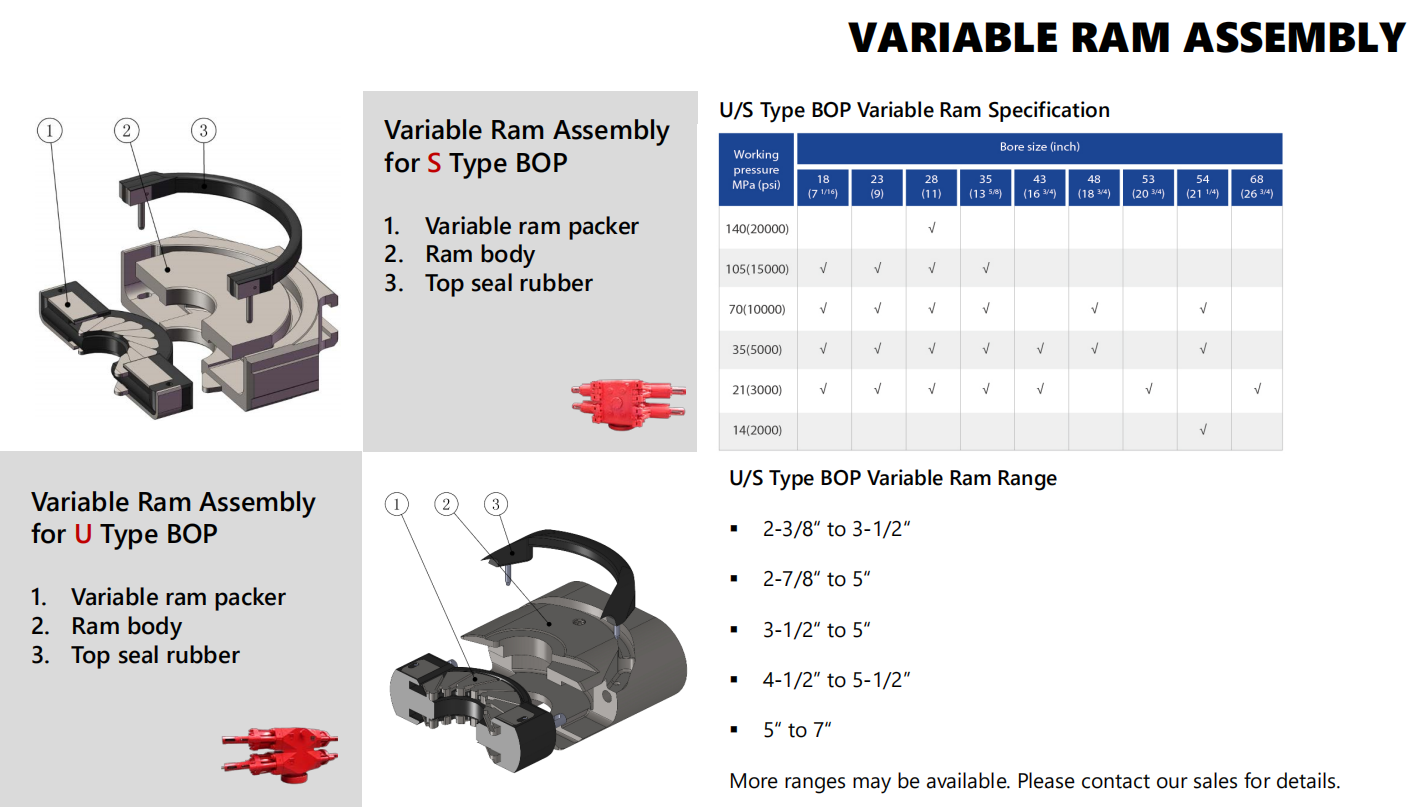

Variable Ram

Variable ram can be used to seal different diameter of pipe string. Variable ram is composed of variable ram, top seal, variable front seal. The installation of variable ram in the BOP is in the same as the common ram, don't need to change any part of the BOP.

1. Variable Ram Rubber 2. Ram Body 3. Top Seal Rubber

Variable Ram Assembly Structure of S type Ram BOP

S Ram BOP Specification&Model

| Operating pressure (psi) | Bore(in) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | \ | \ | \ | \ | \ | \ | \ | \ | \ |

| 105-15000 | S | S | S | S | \ | \ | \ | \ | \ |

| 70-10000 | S | S | S | S | \ | S | \ | \ | \ |

| 35-5000 | S | S | S | S | S | S | \ | S | \ |

| 21-3000 | S | S | S | S | S | \ | S | \ | S |

| 14-2000 | \ | \ | \ | \ | \ | \ | \ | S | \ |

Note:S Ram BOP Specification&Model

S represents S type ram BOP

| Specification&Model | Main Bore mm(in) | Working Pressure MPa(psi) | Oil quantity for opening (Single Cylinder) | Oil quantity for closing(Single Cylinder) | Ram Type | Ram Size (in) | Dimension mm | weight kg | Recommended BOP code | |||||

| length | width | height | single | double | ||||||||||

| single | double | |||||||||||||

| 180(71/16 in)series | (2)FZ18-21 | 179.4(71/16) | 21-3000 | 1.6 | 2 | H | maximum5 9/16 | 1420 | 645 | 568 | 854 | 855 | 1540 | (2)S04.00 |

| (2)FZ18-35 | 179.4(71/16) | 35-5000 | 1.6 | 2 | H | maximum5 9/16 | 1420 | 645 | 624 | 910 | 895 | 1580 | (2)S48.00 | |

| (2)FZ18-70 | 179.4(71/16) | 70-10000 | 2.2 | 2.5 | H | maximum5 9/16 | 1720 | 640 | 897 | 1262 | 1660 | 3020 | (2)S62.00 | |

| (2)FZ18-105 | 179.4(71/16) | 105-15000 | 7.4 | 8 | H | maximum5 1/2 | 1988 | 820 | 922 | 1372 | 3175 | 5885 | (2)S29.00A | |

| 230(9in)series | (2)FZ23-21 | 228.6-9 | 21-3000 | 1.3 | 1.5 | HF | maximum 7 | 1526 | 565 | 580 | 866 | 705 | 1250 | (2)S79.00 |

| (2)FZ23-35 | 228.6-9 | 35-5000 | 4.7 | 5.3 | HF | maximum 7 | 2036 | 720 | 805 | 1190 | 1830 | 3415 | (2)S23.00 | |

| (2)FZ23-70 | 228.6-9 | 70-10000 | 7 | 8 | H | maximum 7 | 2324 | 850 | 1038 | 1518 | 3635 | 6835 | (2)S01.00 | |

| (2)FZ23-105 | 228.6-9 | 105-15000 | 10.2 | 10.9 | HF | maximum 7 | 2170 | 920 | 1140 | 1640 | 4150 | 7500 | (2)S93.00 | |

| 280(11in)series | (2)FZ28-21 | 279.4-11 | 21-3000 | 2.7 | 3.2 | S | maximum 8 5/8 | 1846 | 675 | 740 | 1100 | 1400 | 2550 | (2)S77.00 |

| (2)FZ28-35 | 279.4-11 | 35-5000 | 5.4 | 6.2 | S | maximum 8 5/8 | 2265 | 785 | 895 | 1325 | 2475 | 4550 | (2)S45.00 | |

| (2)FZ28-70 | 279.4-11 | 70-10000 | 7 | 8 | H | maximum 8 5/8 | 2324 | 850 | 1102 | 1582 | 3770 | 6850 | (2)S16.00 | |

| (2)FZ28-105 | 279.4-11 | 105-15000 | 14.6 | 16.7 | H | maximum 8 5/8 | 2650 | 1050 | 1244 | 1784 | 6303 | 11028 | (2)S67.00 | |

| 346(135/8 in)series | (2)FZ35-21 | 346.1(135/8) | 21-3000 | 7.8 | 8.9 | S | maximum 10 3/4 | 2414 | 760 | 774 | 1164 | 2705 | 5115 | (2)S78.00 |

| (2)FZ35-35 | 346.1(135/8) | 35-5000 | 7.9 | 9.3 | S | maximum 10 3/4 | 2415 | 847 | 930 | 1370 | 3010 | 5480 | (2)S103.00 | |

| (2)FZ35-70 | 346.1(135/8) | 70-10000 | 18 | 20.7 | HF | maximum 10 3/4 | 2786 | 1085 | 1276 | 1782 | 6120 | 11135 | (2)S104.00 | |

| (2)FZ35-105 | 346.1(135/8) | 105-15000 | 17.4 | 20 | H | maximum 10 3/4 | 3074 | 1140 | 1420 | 1985 | 8945 | 16070 | (2)S115.00 | |

| 425(163/4 in) | (2)FZ43-35 | 425.5(163/4) | 35-5000 | 10.3 | 11.6 | HF | maximum 10 3/4 | 2923 | 1190 | 1090 | 1570 | 5300 | 9860 | (2)S95.00 |

| 476(183/4 in)series | (2)FZ48-35 | 476.3(183/4) | 35-5000 | 24.5 | 27.9 | HF | maximum 16 | 3430 | 1440 | 1504 | 2072 | 9758 | 12286 | (2)S116.00 |

| (2)FZ48-70 | 476.3(183/4) | 70-10000 | 24.5 | 27.9 | HF | maximum 16 | 3430 | 1440 | 1618 | 2186 | 10312 | 20624 | (2)S102.00 | |

| 527(203/4in) | (2)FZ53-21 | 527.1(203/4) | 21-3000 | 12.2 | 13.6 | HF | maximum 16 | 3424 | 1165 | 1065 | 1650 | 6130 | 13355 | (2)S83.00 |

| 540(211/4 in)series | (2)FZ54-14 | 539.8(211/4) | 14-2000 | 12.1 | 13.8 | HF | maximum 16 | 3300 | 1130 | 940 | 1480 | 5560 | 10200 | (2)S33.00 |

| (2)FZ54-35 | 539.8(211/4) | 35-5000 | 26 | 29.6 | HF | maximum 16 | 3590 | 1445 | 1320 | 1950 | 9270 | 17670 | (2)S105.00 | |

| 680(263/4in) | (2)FZ68-21 | 679.5(263/4) | 21-3000 | 32.6 | 37 | HF | maximum 18 5/8 | 4350 | 1450 | 1250 | 1870 | 12360 | 20290 | (2)S87.00 |

| Note:1. BOP Testing pressure is 1.5 times of standard pressure | ||||||||||||||

| 2. Operating pressure is from 8.4Mpa to 10.5Mpa | ||||||||||||||

S Type Shear Ram Operating specification

| BOP Type | BOP model | Recommended BOP code | Cylinder Type | Specification of drill pipe |

| S | (2)FZ 18-70 | (2)S62.00 | Normal cylinder | \ |

| (2)S92.00 | Cylinder with tandem booster | 4 1/2" 16.6lb/ft G-105 PSL-3 | ||

| (2)FZ28-35 | (2)S45.00 | Large cylinder | \ | |

| (2)S100.00 | Large cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2)FZ 28-70 | (2)S16.00 | Normal cylinder | \ | |

| (2)S02.00 | Large cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2)FZ 35-35 | (2)S103.00 | Normal cylinder | \ | |

| (2)S99.00 | Large cylinder | 5" 19.5lb/ft G-105 PSL-3 | ||

| (2)FZ 35-70 | (2)S104.00 | Normal cylinder | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S112.00 | Large cylinder | 5 1/2" 24.7lb/ft G-105 PSL-3 | ||

| (2)S117.00 | Cylinder with tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2)FZ 35-105 | (2)S115.00 | Normal cylinder | 5" 19.5lb/ft G-105 PSL-3 | |

| (2)S113.00 | Cylinder with tandem booster | 5 1/2" 24.7lb/ft S-135 PSL-3 | ||

| (2)FZ 54-35 | (2)S105.00 | Normal cylinder | 5" 19.5lb/ft G-105 PSL-3 |

S Type Variable Ram Range

| BOP Type | BOP Model | Range of Variable Ram (in) | |||

| S | (2)FZ 18-70 | 2 3/8"-3 1/2" | |||

| (2)FZ28-35 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2)FZ 28-70 | 2 3/8"-3 1/2" | 3 1/2"-5" | |||

| (2)FZ 35-35 | 2 3/8-3 1/2 | 2 7/8"-5" | 4 1/2-5 1/2 | 5-7" | |

| (2)FZ 35-70 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2)FZ 35-105 | 2 3/8-3 1/2 | 3 1/2-5" | 4 1/2-5 1/2 | 5-7" | |

| (2)FZ 54-14 | 4 1/2"-5 1/2" | ||||

| (2)FZ 53-21 | 4 1/2"-5 1/2" | ||||

| (2)FZ 54-35 | 4 1/2"-5 1/2" | ||||

U Type Ram BOP

Structual Feature

● Pressurized components are forging matierals, having good strength and impact toughness, avoid the forging default.

● Middle flange uses combined seal, its switch is operated by hydraulic pressure, easy to change the ram.

● Equipped with auxiliary oil cylinder, compared with the traditional shear ram BOP, it has the function, smaller volume.

● Ram rubber is abundant, and use self-contained seal.

● Manual locking device belongs to the standard configuration, In the event of hydraulic loss, it can ensure that ram remains closed.

● Manual and hydraulic locking device and auxiliary oil cylinder can be equiped according to customer's requirements flexibly, and easy to interchange.

● The internal shell of BOP resistant to low temperature can process pipeline, to make the steam flow inside the BOP, radiat heat. (for costumer’s option).

● The internal part of BOP resistant to high sulfer which contact the well liquid has Surfaced high nickel base alloy, which can achieve the highest levels of resistance to H2S and CO2.

Ram Assembly

● Pipe Ram

1. Top seal rubber 2. Ram body 3. Front seal rubber

U type Ram structure sketch

Shear Ram

Shear ram can cut pipe the well, blindly close the wellhead, and also used as blind ram when there is no pipe in the well. The installation of shear ram is the same with the original ram.

● In the normal condition used as blind ram, in case of emergency, used as shear ram.

● Shear damper can be repeatedly cut pipe and not damage the blade, The weared the blade can be reused after the repair. Shenkai produces the shear ram with shear life in more than five times, Allowed to replace the sealing rubber.

● The ordinary ram blade is integrated with the ram body.

● The ram blade of BOP resistant to high sulfer is separated with the ram body, which is easy to change blade after blade damaged, and make the ram body be able to repeated use.

● The contact sealing surface between top seal of shear ram and blade is large, which effectively reduce the pressure on the rubber sealing surface, and prolong its life.

1. Down shear ram 2. Set srew 3. Left seal 4. Up blade

5. Top seal rubber 6. Up shear ram body

7. Blade seal 8. Set screw 9. Right seal 10. Down blade

Shear Ram Assembly Structure of U type Ram BOP resistant to high sulfer

1. Down shear ram body 2. Left seal rubber

3. Up shear ram body 4. Top seal rubber

5. Right seal rubber 6. Blade seal

Shear Ram Assembly Structure of U type Ram BOP

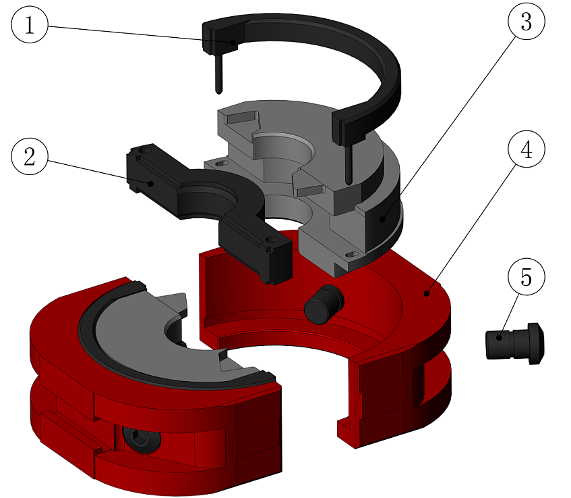

Variable Ram

Variable ram can be used to seal different diameter of pipe string. Variable ram is composed of variable ram, top seal, variable front seal. The installation of variable ram in the BOP is in the same as the common ram, don't need to change any part of the BOP.

1. Variable Ram rubber 2. Ram body 3. Top seal rubber

Variable Ram Assembly Structure of U type Ram BOP

BOP with side door

Bonnet type ram BOP is mainly used in overhaul, control in the process of fracturing and drilling well head pressure.

● Small volume, light weight, simple and compact structure.

● Replacing ram simply needs to unscrew the side cover nut, remove the side cover board, simple and convenient; it doesn`t need to disconnect the hydraulic pipeline, this effectively prevents the pollution of hydraulic oil.

BOP with side door specification

| Specification | |

| model | 2FZ18-35SE |

| bore | 179.4mm(7 1/16〃) |

| rated working pressure | 35MPa(5000psi) |

| immobile water pressure test pressure | 52.5Pa (7500psi) |

| rated hydraulic operating pressure | 21 MPa(3000psi) |

| recommended hydraulic operating pressure | 8.4~10 .5MPa(1200~1500psi) |

| Valume of opening cylinder | 1.4L/个(0.37 US Gal/set) |

| valume of closing cylinder | 1.3L/个(0.34 US Gal/set) |

| temperature class | T-20 |

| assembled ram type | 3 1/2”pipe ram 、blind ram |

| weight | 1200kg(2643Lbs) |

Feature

● Rubber core store glue big quantity , small friction resistance, when switch pressure sealing ability.

● Using hemispherical head, no stress concentration phenomenon when under pressure, casing stress evenly, easy to tear open outfit.

● Piston stroke is short, low height, and set the wear ring.

● The lip seal, long service life.

● Low temperature processing annular blowout preventer shell diameter has a trough steam pipe, pipe ventilation with saturated vapor, round shell for heating.( For the customer to choose ).

● High sulfate-resistant blowout preventer internal all parts contact well liquid surfacing high nickel base alloy, can achieve the highest levels of resistance to effect such as H2S and CO2. For the customer to choose.

Annular BOP element specification& Model

Working pressure MPa(psi) | Main bore mm(in) | |||||||||

| 179.4-7 1/16 | 228.6-9 | 279.4-11 | 346.1-13 5/8 | 425-16 3/4 | 476-18 3/4 | 527-20 3/4 | 539.8-21 1/4 | 749.3-29 1/2 | 762-30 | |

| 3.5(500) | — | — | — | — | — | — | — | — | — | — |

| 7(1000) | — | — | — | — | — | — | — | — | — | ● |

| 14(2000) | — | — | — | — | — | — | — | — | — | — |

| 21(3000) | ● | ● | ● | ● | — | — | — | — | — | — |

| 35(5000) | ● | ● | ● | ● | ● | — | — | — | — | — |

| 70(10000) | ● | — | ● | ● | — | ● | — | — | — | — |

Note:●Tands for spherical type

Spherical type annular bop and packing element specification

| Model | Main bore mm(in) | Working pressure MPa(psi) | Operating Pressure MPa | Connection type | Dimensionmm mm | Recommended bop code | weight kg | ||

Top | Bottom | Outside diameter | Height | ||||||

| FH18-21 | 179(7 1/16) | 21(3000) | 8.4~10.5 | studded | fanged | 737 | 743 | FH1821NL-00 | 1350 |

| FH18-35 | 35(5000) | 737 | 790 | FH1835NL-00 | 1572 | ||||

| FH18-70/105 | 70(10000) | 1092 | 1136 | H09.00 | 5070 | ||||

| FH23-21 | 228(9) | 21(3000) | 900 | 830 | FH2321-00 | 2104 | |||

| FH23-35 | 35(5000) | 998 | 1200 | H14.00 | 3540 | ||||

| FH28-21 | 279(11) | 21(3000) | 1013 | 838 | FH2821NL-00 | 2574 | |||

| FH28-35 | 35(5000) | 1138 | 1081 | FH2835-00 | 4410 | ||||

| FH28-35/70 | 35(5000) | 1138 | 1096 | FH2835/70-00 | 4451 | ||||

| FH28-70/105 | 70(10000) | 1448 | 1420 | FH2870/105-00 | 10800 | ||||

| FH35-35 | 346(13 5/8) | 35(5000) | 1270 | 1160 | FH3535-00 | 6400 | |||

| FH35-35/70 | 35(5000) | 1270 | 1227 | FW1305-00A | 6843 | ||||

| FH35-70/105 | 70(10000) | 1640 | 1664 | FH3570-00 | 15110 | ||||

| FH43-35 | 425(16 3/4) | 35(5000) | 1524 | 1320 | H24.00 | 10834 | |||

| FH48-70 | 476(18 3/4) | 70(10000) | 1937 | 1882 | H26.00 | 27161 | |||

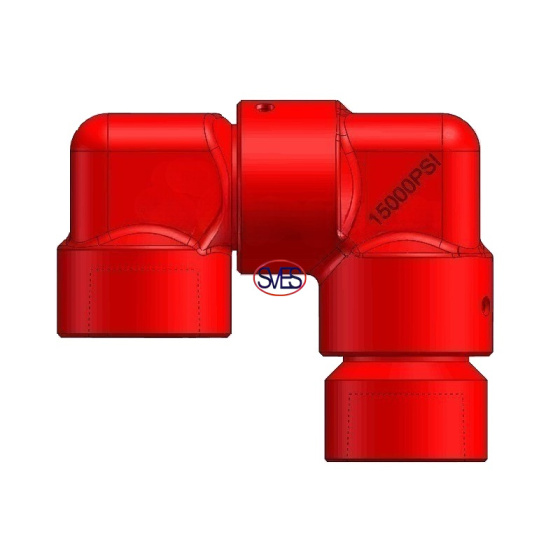

Taper type annular BOP

Feature

● The lip seal, has a self-sealed capability, it is more reliable.

● A bore in piston with stroke test, can measure rubber`s life.

● The claw plate connection, reliable connection, the shell stress even and convenient installation.

● Upper pistons for cone, the product outside diameter is small.

● Friction surface with abrasion proof plate, protect the header, easy to replace.

Taper Type annular BOP

Working pressure MPa(psi) | Main bore mm(in) | |||||||||

| 179.4-7 1/16 | 228.6-9 | 279.4-11 | 346.1-13 5/8 | 425-16 3/4 | 476-18 3/4 | 527-20 3/4 | 539.8-21 1/4 | 749.3-29 1/2 | 762-30 | |

| 3.5(500) | — | — | — | — | — | — | — | — | ▲ | — |

| 7(1000) | — | — | — | — | — | — | — | — | — | ▲ |

| 14(2000) | — | — | — | — | — | — | — | ▲ | — | — |

| 21(3000) | — | — | — | ▲ | ▲ | — | ▲ | — | — | — |

| 35(5000) | — | — | — | ▲ | ▲ | — | — | ▲ | — | — |

| 70(10000) | — | — | — | ▲ | — | ▲ | — | — | — | — |

Note:▲Stands for typer Type

Taper Type annular BOP and packing element specification

| Model | Main bore mm(in) | Working pressure MPa(psi) | Operating Pressure MPa | Connection type | Dimensionmm mm | Recommended bop code | weight kg | ||

Top | Bottom | Outside diameter | Height | ||||||

| FHZ35-21 | 346(13 5/8) | 21(3000) | 8.4~10.5 | studded | fanged | 1296 | 1203 | H13.00 | 4693 |

| FHZ35-35 | 35(5000) | 1340 | 1350 | H28B.00 | 5713 | ||||

| FHZ43-21 | 425(16 3/4) | 21(3000) | 1386 | 1368 | H16.00 | 6180 | |||

| FHZ53-21 | 527(20 3/4) | 21(3000) | 1452 | 1463 | H15.00 | 7873 | |||

| FHZ54-14 | 540(21 1/4) | 14(2000) | 1516 | 1337 | H33.00 | 6780 | |||

| FHZ54-35 | 35(5000) | 2065 | 2055 | H27B.00 | 21475 | ||||

Our company produces the design and manufacture of diverters according to API 16 a, flange specifications in accordance with ASME B16.47 standard for《 large diameter pipe steel flange 》requirements. 29 1/2 "- 500 psi diverter`s top and bottom connections are class 300 B16 / A NPS30 R95, 30" - 1000 psi diverter`s top and bottom connections are class 600 B16 NPS30 R95 / A.

Diverter and packing element specification form

| Model | Main bore mm(in) | Working pressure MPa(psi) | Operating pressureMPa | Connection type | Dimension mm | Recommended bop type | weight kg | ||

| Top | Bottom | Outside diameter | Height | ||||||

| FFZ75-3.5 | 749.3(29 1/2) | 3.5(500) | 8.4~10.5 | studded | fanged | 1910 | 1798 | H06.00C | 12607 |

| FFZ76-07 | 762 (30) | 7(1000) | 1805 | 1700 | H31.00 | 13866 | |||

| 29 1/2”-500 psi Diverter top&bottom connection: class 300 B16/A NPS30 R95 | |||||||||

| 30”-1000 psi Diverter top&bottom connection: class 300 B16/A NPS30 R95 | |||||||||

With pressure working BOP is the core of the pressure equipment device, through the bop sealing rubber core of open and closed to control the wellhead sealing, and complete with pressure process. Ram BOP shell chamber, the annular blowout preventer piston adopts reliable surface wear-resistant anti-corrosion technology, suitable for operation under pressure annular blowout preventer high frequency switching requirements.

Belt pressure operation BOP main technical specification:

| Specification | |

| Model | FZ18-35A |

| Bore | 179.4mm(7 1/16〃) |

| Rated working pressure | 35MPa(5000psi) |

| Immobile water pressure test pressure | 52.5Pa (7500psi) |

| Rated hydraulic operating pressure | 21 MPa(3000psi) |

| Recommended hydraulic operating pressure | 8.4~10 .5MPa(1200~1500psi) |

| Weight | 1267kg(2793Lbs) |

| Dimension | 1832mm×858mm×701mm |

■ Suitable for coiled tubing operation, effectively prevent the blowout accident, and ensure safety operation

■ Typical coiled tubing well control device including the bop and stuffing box

■ Stuffing box using side door open form, simple and easy to replace the rubber core even in coil tubing operation

■ Adopt dual cylinder structure, use well pressure to seal, long usage life and less control pressure

■ Equipped with blind ram, shear ram, slip ram and pipe ram

■ Slips ram using removable structure design, unique tooth profle design can reduce the harm for coil tubing

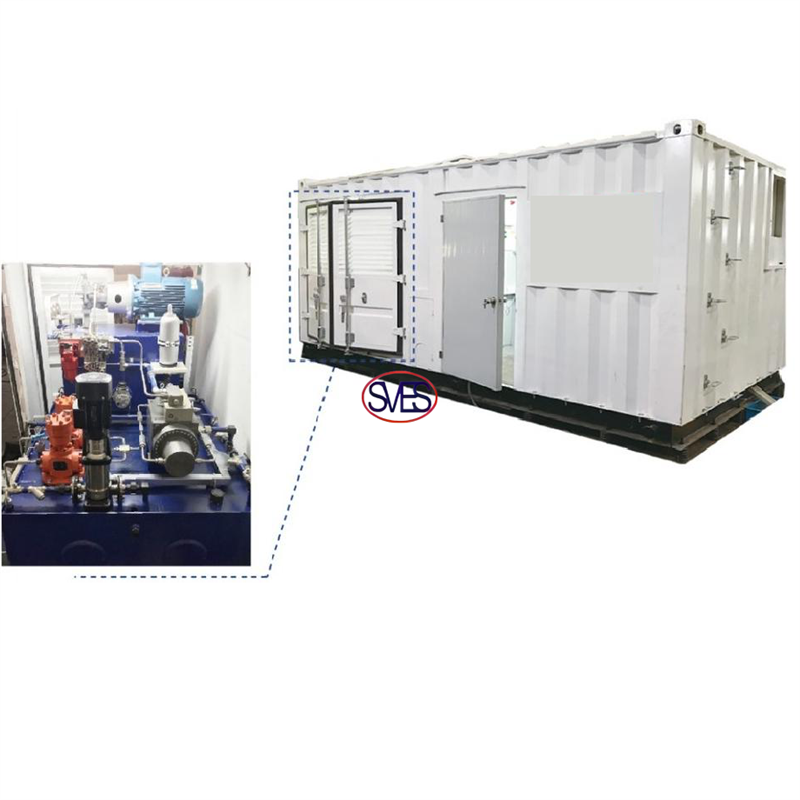

Koomey Unit,BOP Control System

BOP CONTROL SYSTEM

Complied with API Spec 16D<Specification for control system of well head control equipment and distribution equipment>,Also can be customized according to the special requirements of Client, applying variety of explosion-proof technology, meet the European CE/ATEX certification standards.

Advanced Profibus and PLC control technology to simplify the operation automatically.

Cable or fiber connection between main control panel and auxiliary driller' s panel,The distance can be over 200 meters and fast response speed

Equip with external hydraulic source and nitrogen backup system source, ensure normal operation under unexpected circumstances

Equip with backup power supply, the control unit can work normally for more than 120 minutes in case of sudden power failure, ensuring continuous and safe operation

Optional PN-T remote console automatic recording module can provide data traceability for remote console operation

Strong applicability, applied in a variety of harsh conditions(high and low temperature, offshore)stably

Compatible with most international drilling instruments, can realize integrated monitoring function

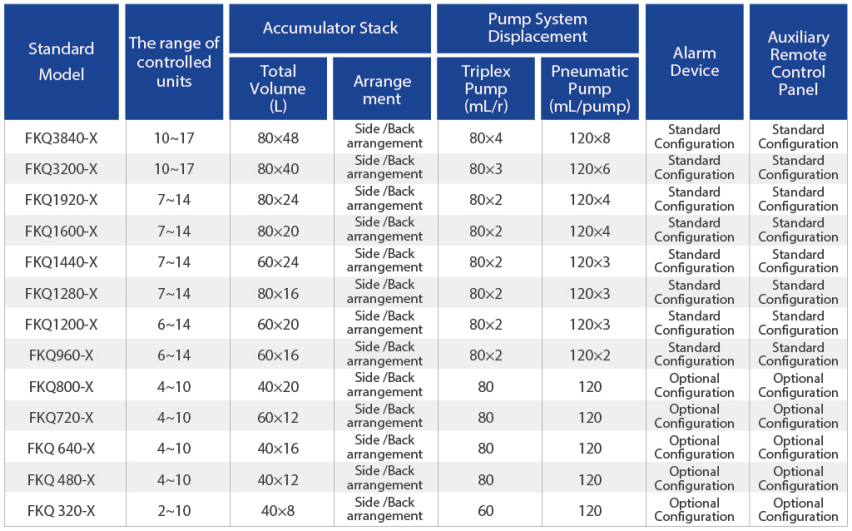

Pneumatic Type BOP Control System Configuration and Parameter:

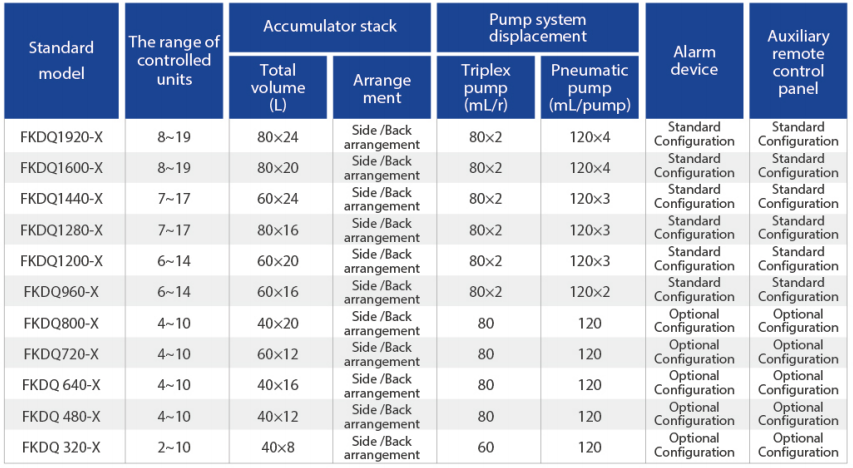

Electric Type BOP Control System configuration and Parameter:

1. FKQ3200-12 Light indicating type BOP control system

The whole system adopts inductive sensor control technology, and each BOP switch status can realize real-time synchronization between two remote control panels.

■ Better cost effective compared with electric control system, it has the same position display function and response speed

■ More accurate and faster response speed: relative air circuit signal shows the rotary valve position;the electrical signal transmission speed is faster. Field staffs are able to know the equipment status faster and more accurately, which avoids the inconsistency of the traditional remote control valve position switch status

■ Better stability:electrical signals avoid mechanical errors, solving the problem of signal failure caused by the internal block of the gas bundle during the transmission of the gas signal

2. FKDQ Electric Control System

The whole system is equipped with backup power supply, which can operate normally for 120 minutes in case of power failure in field, ensuring continuous and safe field operation

■ Advanced fieldbus technology and PLC control technology, simple operation and automation

■ Operation indication and anti-error function in the driller's panel, easy and reliable operation

■ Strong adaptability, can operate stably under a variety of harsh working conditions

■ The whole equipment certified by API, IEC and ATEX

■ Optional PN-T automatic recording module provides data traceability for remote console operation process Compatible with our own drilling instruments, can realize integrated monitoring function

3.FKWDQ Wireless BOP Remote Control System:

■ Advanced wireless remote control technology, the control distance can reach hundreds of meters, short control lag time, not affected by the ambient temperature. This system overcomes the shortcoming of fixed point operation control, and improves the safety and convenience of drilling operation

■ Optional PN-T automatic recording module provides data traceability for remote console operation process

■ Hand-held terminal operation can realize the function of remote shut-down in emergency, and improve the safety of the BOP switch control and the reliability of the emergency treatment when blowout occurs

■ Compatible with our own drilling instruments, can realize integrated monitoring function

■ Operation indication and anti-error function in the driller's panel, easy and reliable operation

■ The whole system equip with backup power supply, which can operate normally for 120 minutes in case of power failure in field, ensuring continuous and safe field operation

■ The whole equipment certified by API,IEC and ATEX

4.Rapid Charging BOP Control System:

■ Internal integration volume is small and automatically reversiable, can also achieve continuous pressurize

■ The system customized for pressure test for well control products such as BOP and manifold, and the pressurization speed can reach more than 5 times of the conventional pressure test system

■ Windows operating interface, easy operation and with clear picture

■ With manual and automatic pressure test function, data computer storage, and no data loss in case of power loss

■ Customized according to customer requirements (including operation room, monitor equipment,etc)