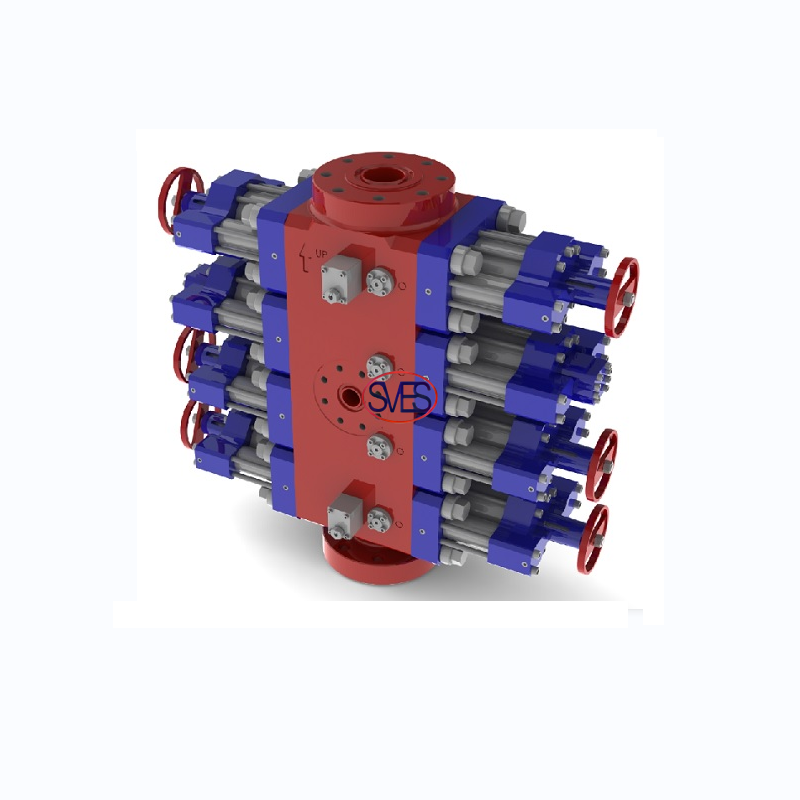

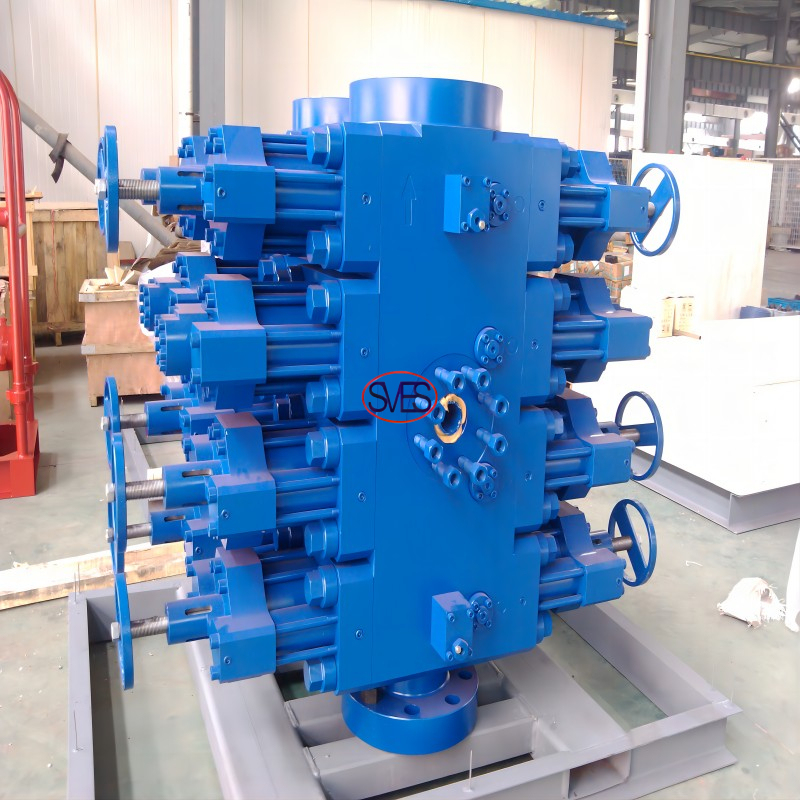

Coiled Tubing Blowout Preventer(BOP)

Coiled Tubing Blowout Preventer (BOP)

Product Description

The coiled tubing BOP is applied to coiled tubing operation, flushing well,formation testing, flowing back. It achieves the safety production and prevent from blowout accident, protect the surrounding environment.

A coiled tubing blowout preventer (BOP) is a device that seals off the wellbore and prevents the uncontrolled release of oil, gas, or water during coiled tubing operations. Coiled tubing BOPs have different types of rams, such as pipe rams, slip rams, shear rams, and blind rams, that can close around the coiled tubing or seal off the well completely. Coiled tubing BOPs are essential for well control and safety in applications such as drilling, workover, and testing.

Feature

It is applied to high pressure wellhead and H2S condition.

Hydraulic drive, respond rapidly.

The indicating arm of ram stroke are equipped, it is convenience to show the working condition of ram.

The blind ram, shearing ram, slip ram and pipe ram are equipped inside BOP.

Set the manual locking, the safety factor and the reliability are high.

Specification

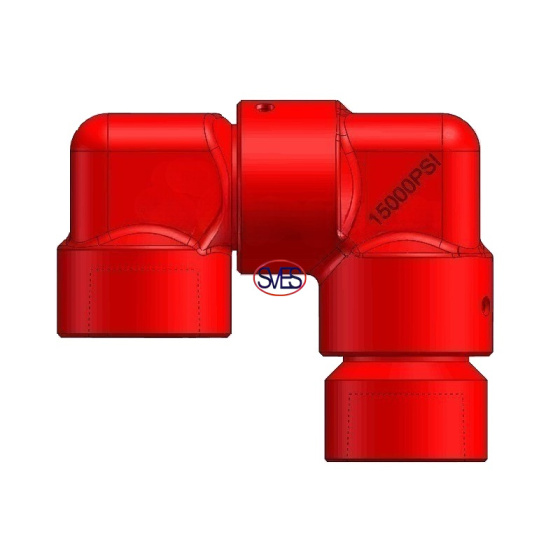

Working Pressure:70.0MPa(10,000psi)~105MPa(15,000psi)

Bore:62mm、78mm、100mm、103mm、130mm、180mm

Temperature Grade:T-20

Side outlet Specification: 52mm (2-1/16”)

Working Medium:Oil, mud, drilling fluid Hydrogen sulfide gas

| Nominal Bore Diameter | 2-9/16"~5-1/8" |

| Working Pressure | 2000psi~20000psi |

| Recommended Operating Pressure | 1500psi (2800psi for shear ram) |

| Side Outlet | 2-1/16"×10000psi |

| Size of Pipe be Sheared | OD 2-3/8", wall 0.204" , CT110 class |

| Slip Rams' Holding Weight | 40T (2" coil tubing) |

| Temperature Class for Metallic Material | T75, T-20, T0 |

| Executive Standard | API 16A 、 API RP 16ST latest edition |

| Working Medium | petroleum, natural gas, water, mud, gas containing H2S, CO2 |