- Home

- >

- Products

- >

- Casing Centralizer

- >

Casing Centralizer

1.Single Bow Spring Centralizer

Product Description:

Single bow spring centralizers provide excellent downhole durability and performance. These centralizers feature heat-treated, spring-steel bows that are welded to rigid end collars.

Feature:

High-performance bows provide maximum standoff in multiple locations of the annulus, providing the best possible conditions for primary cement to achieve zonal isolation;

All centralizer sizes have been tested and validated to meet American Petroleum Institute (API) 10D requirements, providing reliability and durability during operations;

Non-welded design can withstand most wellbore environments, providing operational flexibility;

Bow configurations are available in various heights and sizes suitable for most applications and providing a variety of bow configurations for special applications;

Suited for vertical and deviated wellbore.

2. Double Bow Centralizer

Product Description:

High quality double bow centralizers are made of special alloy steel and hot formed in totally controlled heat treatment plant to achieve the uniform hardness all over.

Spec and performance index of bow spring casing centralizer meet API Spec 10D.

The double bow centralizer is connected by pin when in use, the unfolded centralizer can be stacked flatly for convenient storage and transportation.

Feature:

Provides superior standoff with reduced running forces when compared to conventional bow-spring centralizers;

All centralizer sizes have been tested and validated to meet American Petroleum Institute (API) 10D requirements,providing reliability and durability during operations;

Suited for vertical and deviated wellbore; Primarily suited for horizontal and directional wellbores .

Product Description:

Turbolizer Centralizer are designed with deflector blades. The special blades are riveted to heat-treated bows and are designed to deflect fluid flow in a turbulent spiral.

This effect helps break up drilling mud when running casing and improves mud removal during circulation. It provides additional fluid agitation for cementing benefits in critical zones.

Features:

Equipped with right or left handed deflector fins which contributes to a high-quality primary cement job;

Meet API Specification 10D requirements;

Fins are heat treated spring steel.

4.Slip-on One Piece Standard Bow Centralizer

Product Description:

The new one-piece style centralizers are made from one piece of steel plate. The plate is cut by laser, rolled for forming,welded using high-temperature wire saw.Then the bows of centralizer are formed by an hydraulic machine; at last the centralizers are powder coated after heat treatment.

Features:

One-piece construction design;

Sizes are available from 2 7/8” to 20” ;

High stand-off(+85°/C) and high restoring force;

Straight bows can provide maximum lateral support;

Completely fit with casings in a ledge wellbore condition;

Reduces frictional drag and torque;

Max O.D. is the same as wellbore;

Zero starting force;

All performances can exceed API 10D requirements;

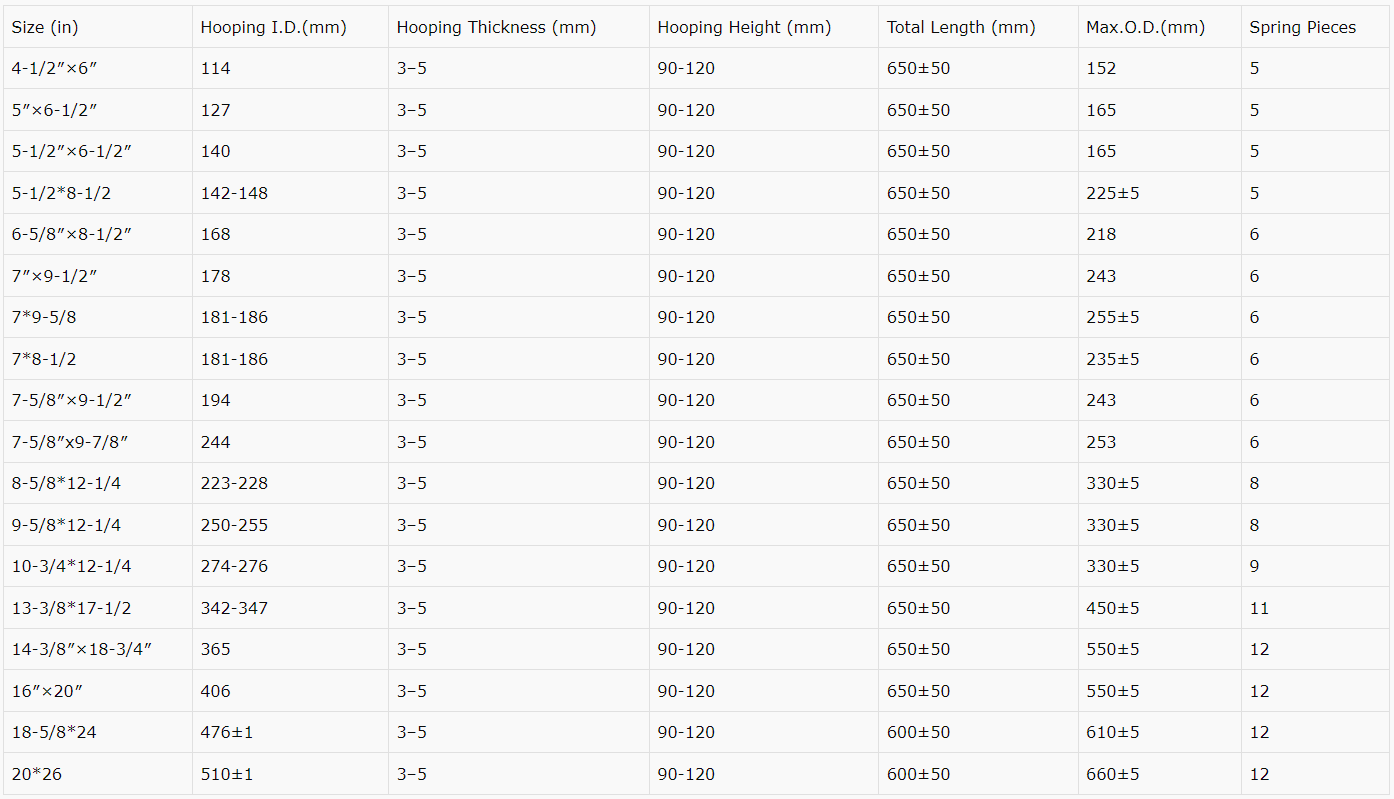

Technical Specification:

Hinged Welded Bow Centralizer, Non-welded Bow Centralizer

Product Description:

This type of centralizer is built using steel or cast iron and works well with the deviated wellbores. It is not as effective as bow-spring centralizers.Rigid centralizers are slightly smaller than the well bore.

They are more commonly used in deviated or horizontal well bores where the weight of the casing string would cause a bow spring centralizer to experience eccentric compression which could jeopardize the seal.

(The rigid casing centralizer can be divided into ordinary rigid centralizer and roller rigid centralizer.)

Features:

1-The rigid centralizers are generally constructed in one piece to add greater strength and are held in place by high loads top collars or set screws;

2-The tools are designed to improve cement flow while promoting maximum standoff from the borehole;

3-Provide either straight blade or spiral blade.

4-Can provide aluminum alloy material, and cast steel material.

Rigid centralizers provide a wide range of options for casing centralization, from standard vertical well configurations to highly deviated and horizontal wells.

Their high-quality construction provides great strength and down hole integrity.