- Home

- >

- Products

- >

- Casing Slip

- >

Casing Slip

Model | Size Range (in) | Size Range (in) | Rated Capacity (short tons) |

WGY275 | 2. 3/8〜7. 5/8 | 27. 1/2 | 350 |

WGY375 | 2. 3/8〜14 | 37. 1/2 | 550 |

WGY495 | 2. 3/8〜20 | 49. 1/2 | 750 |

Size(in) | Inserts | Slip Body Size | |

P/N | Qty | ||

2. 3/8 | 24777 | 18 | 3. 1/2 |

2. 7/8 | 25780 | 18 | |

3. 1/2 | 16441 | 18 | |

3. 1/2 | 24779 | 27 | 4. 1/2 |

4 | 24781 | 27 | |

4. 1/2 | 16408 | 27 | |

4. 1/2 | 24785 | 27 | 5. 1/2 |

5 | 24783 | 27 | |

5. 1/2 | 16407 | 27 | |

6. 5/8 | 25474 | 45 | 7. 5/8 |

7 | 26750 | 45 | |

7. 5/8 | 16407 | 45 | |

Rotary Table Size (in) 27. 1/2 | |||

Rated Capadty(short tons) 250 | |||

Working Pressure(Mpa) 17. 5 | |||

Max. Pressure(Mpa) 21 | |||

Size(in) | Inserts | Slip Body Size | Size(in) | Inserts | Slip Body Size | |||||

P/N | Qty | P/N | Qty | |||||||

2.3/8 | 001605136 | 16 | 3.1/2 | 9.1/8 | 001605745 | 64 | 9.5/8 | |||

001605137 | 8 | 001605746 | 32 | |||||||

2. 7/8 | 001605138 | 16 | 9. 5/32 | 001605825 | 64 | |||||

001605139 | 8 | 001605827 | 32 | |||||||

3. 1/2 | 001605140 | 24 | 9.1/2 | 001605383 | 96 | |||||

4 | 001605243 | 32 | 5. 1/2 | 9.5/8 | 2633 | 96 | ||||

001605244 | 16 | 9.3/4 | 2649 | 96 | ||||||

4. 1/2 | 2168 | 32 | 9. 7/8 | 2649 | 96 | |||||

2168B | 16 | 10. 1/4 | 001605688 | 80 | 11.3/4 | |||||

4.3/4 | 001605701 | 32 | 001605689 | 40 | ||||||

001605702 | 16 | 10. 7/16 | 001605826 | 80 | ||||||

5 | 2169 | 32 | 001605828 | 40 | ||||||

2169B | 16 | 10. 3/4 | 2640 | 80 | ||||||

5. 1/2 | 2170 | 48 | 2640B | 40 | ||||||

5.3/4 | 001605753 | 48 | 5. 7/8 | 10. 7/8 | 2650 | 80 | ||||

5. 7/8 | 001605752 | 48 | 2650B | 40 | ||||||

6. 5/8 | 2632 | 36 | 7. 5/8 | 11 | 001605430 | 80 | ||||

2632B | 24 | 001605431 | 40 | |||||||

7 | 2623 | 48 | 11.1/8 | 001605384 | 80 | |||||

2623B | 24 | 001605385 | 40 | |||||||

7. 1/8 | 001605745 | 48 | 11.1/4 | 001605371 | 80 | |||||

001605746 | 24 | (X)1605372 | 40 | |||||||

7. 1/2 | 001605383 | 72 | 11.55 | 001605861 | 120 | |||||

7. 5/8 | 2633 | 72 | 11.3/4 | 2637 | 120 | |||||

7. 3/4 | 2649 | 72 | 11. 7/8 | 2651 | 120 | |||||

8 | 001605265 | 64 | 9.5/8 | 12.3/4 | 001605340 | 80 | 14 | |||

001605266 | 32 | 001605341 | 40 | |||||||

8. 1/8 | (X)1605338 | 64 | 13.3/8 | 2636 | 80 | |||||

001605339 | 32 | 2636B | 40 | |||||||

8. 1/2 | 001605682 | 64 | 13. 1/2 | 2652 | 80 | |||||

001605683 | 32 | 2652B | 40 | |||||||

8.5/8 | 2640 | 64 | 13.5/8 | 2653 | 80 | |||||

2640B | 32 | 2653B | 40 | |||||||

8.3/4 | 2650 | 64 | 13.3/4 | 2655 | 80 | |||||

2650B | 32 | 2655B | 40 | |||||||

8.9 | 001605470 | 64 | 14 | 2635 | 120 | |||||

001605471 | 32 | |||||||||

9 | 001605248 | 64 | ||||||||

001605249 | 32 | |||||||||

Rotary Table Size (in) | 37.1/2 | |||||||||

Rated Capadty(short tons) | 4448、 500 | |||||||||

Working Pressure(Mpa) | 17. 5 | |||||||||

Max. Pressure(Mpa) | 21 | |||||||||

| Model | Size(in) | Rated Capacity (short tons) | |

| Pipe Type | Pipe Size (in) | ||

| WGY2. 3/8-20-495 | Drill Collar | 4,4.1/4,4.3/8,4.5/8,4 3/4 | 225 |

| Tubing/Drill Pipe | 2.3/8,2.7/8,3.1/8,3. 1/2 | 350 | |

| Drill Collar | 5.5/8,5.3/4,6,6.1/4,6 1/2, 6. 3/4,7 1/4,7 3/8,7 1/2 ,7.5/8, 7.3/4,8,8 1/8,8 1/4 | ||

| 8 1/2,8 5/8, 8 3/4, 9 | |||

| 9 1/4, 9 1/2 | |||

| Tubing/Drill Pipe | 4 | 500 | |

| Casing/Drill Pipe | 4 1/2,5, 5 1/2, 5 11/16, 5 7/8,6 | ||

| 6. 9/64, 6 1/2, 6 5/8, 6 7/8, 7,7 5/8 | |||

| Casing | 7.3/4, 8.5/8,9.1/8,9.1/2,9. 5/8, 9.7/8,10,10.3/4,10.7/8,11,11. 1/8 | ||

| Casing/Drill Pipe/Tubing | 4.1/2,5,5.1/2,5.7/8,6. 1/2 | 750 | |

| Casing/Drill Pipe | 6. 5/8,7,7. 5/8 | ||

| Casing | 9.5/8,9.7/8,10.3/4,11.3/4,11.7/8 | ||

| 12.3/4,13.3/8,13.5/8,14,16 | |||

| 17.7/8,18,18.5/8,20 | |||

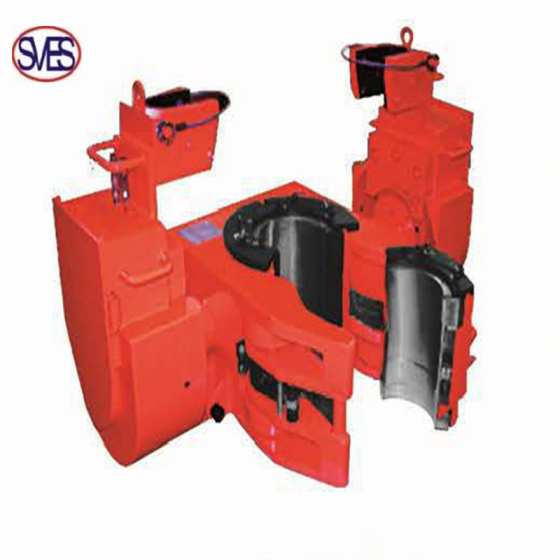

WQ series pneumatic slips are pneumatic operation tools for screwing down drill pipes and clamping casings during the drilling operation of petroleum and natural gas work. It is applicable for various rotary tables. The pneumatic slips are characterized by high degree of mechanical work, convenient operation, large lifting force, wide application range, safety and reliability. They are capable of reducing the labor intensity and improving the operation by a large scale. In the operation of screwing down the drill pipe, automatic silt scraping can be conducted. The pneumatic slips are designed and manufactured according to requirements of API Spec 7K Specification for drilling and well serving equipment.

| Model | Size (in) | Rotary Table Size (in) | Rated Capacity (short tons) | Position into Rotary Table | ||

| WQ-275 II | 2. 3/8〜9. 7/8 | 27. 1/2 | 350 | higher than the drill floor | ||

| WQ-275 III | 2. 3/8〜7. 5/8 | 27. 1/2 | 350 | Flush Mounted | ||

| WQ-375 III | 2. 3/8〜14 | 37. 1/2 | 500 | higher than the drill floor | ||

| WQ-375 IV | 2. 3/8〜14 | 37. 1/2 | 500 | Flush Mounted | ||

| Size(in) | Slip Body Size | Inserts P/N | Inserts Qty | ||

| WQ-275 II | WQ-275 III | WQ-375 111、IV | |||

| 2. 3/8 | 3. 1/2 | 1605136 | 12 | 12 | 16 |

| 1605137 | 8 | 8 | 8 | ||

| 2. 7/8 | 3. 1/2 | 1605138 | 12 | 12 | 16 |

| 1605139 | 8 | 8 | 8 | ||

| 3. 1/2 | 3. 1/2 | 1605140 | 20 | 20 | 24 |

| 4 | 5. 1/2 | 1605243 | 24 | 24 | 32 |

| 1605244 | 16 | 16 | 16 | ||

| 4. 1/2 | 5. 1/2 | 2168 | 24 | 24 | 32 |

| 2168B | 16 | 16 | 16 | ||

| 4. 3/4 | 5. 1/2 | 1605701 | 24 | 24 | 32 |

| 1605702 | 16 | 16 | 16 | ||

| 5 | 5. 1/2 | 2169 | 40 | 40 | 32 |

| 2169B | 40 | 40 | 16 | ||

| 5. 1/2 | 5. 1/2 | 2170 | 40 | 40 | 48 |

| 5. 3/4 | 5. 7/8 | 1605753 | / | / | 48 |

| 5. 7/8 | 5. 7/8 | 1605752 | / | / | 48 |

| 6. 5/8 | 7. 5/8 | 2632 | 36 | 36 | 48 |

| 2632B | 24 | 24 | 24 | ||

| 7 | 7. 5/8 | 2623 | 36 | 36 | 48 |

| 2623B | 24 | 24 | 24 | ||

| 7. 1/8 | 7. 5/8 | 1605745 | 36 | 36 | 48 |

| 1605746 | 24 | 24 | 24 | ||

| 7. 1/2 | 7. 5/8 | 1605383 | 60 | 60 | 72 |

| 7. 5/8 | 7. 5/8 | 2633 | 60 | 60 | 72 |

| 7. 3/4 | 7. 5/8 | 2649 | 60 | 60 | 72 |

| 8 | 9. 5/8 | 1605265 | 48 | / | 64 |

| 1605266 | 32 | / | 32 | ||

| 8. 1/8 | 9. 5/8 | 1605338 | 48 | / | 64 |

| 1605339 | 32 | / | 32 | ||

| 8. 1/2 | 9. 5/8 | 1605682 | 48 | / | 64 |

| 1605683 | 32 | / | 32 | ||

| 8. 5/8 | 9. 5/8 | 2640 | 48 | / | 64 |

| 2640B | 32 | / | 32 | ||

| 8. 3/4 | 9. 5/8 | 2650 | 48 | / | 64 |

| 2650B | 32 | / | 32 | ||

| 8. 9 | 9. 5/8 | 1605470 | 48 | / | 64 |

| 1605471 | 32 | / | 32 | ||

CMS series casing slips are designed in a structure of multi-segment pieces with firm structure, light weight and large holding range, which is easy to fit the changing of the external diameter of the casing pipes due to wear and tear. They are designed and manufactured in API Spec 7K Drilling slips.

Domestic Model | International Model | Casing OD | Inserts P/N-Qty | 卡瓦体片数 Slip Segment Qty | 额定载荷 Rated Capacity (short tons) | |

in | mm | |||||

WG-4.1/2 | CMS-XL4.1/2〜5 | 4. 1/2 | 114. 3 | 2628 - 108 | 9 | 250 |

WG-5 | CMS-XL4.1/2〜5 | 5 | 127 | 2628 - 108 | 9 | |

WG-5.1/2 | CMS—XL5.1/2〜6 | 5. 1/2 | 139. 7 | 2620 - 108 | 9 | |

WG-6 | CMS-XL5. 1/2 — 6 | 6 | 152. 4 | 2620 - 108 | 9 | |

WG-6. 5/8 | CMS-XL6.5/8 | 6. 5/8 | 168. 3 | 2628 - 144 | 12 | |

WG-7 | CMS-XL7 | 7 | 177. 8 | 2619 - 144 | 12 | |

WG-7. 5/8 | CMS-XL7. 5/8 | 7. 5/8 | 193. 7 | 2630 - 144 | 12 | |

WG-8. 5/8 | CMS-XL8. 5/8 | 8. 5/8 | 219. 1 | 2630 - 156 | 13 | |

WG-9.5/8 | CMS-XL9. 5/8 | 9. 5/8 | 244. 5 | 2630 - 168 | 14 | |

WG-10. 3/4 | CMS-XL10. 3/4 | 10. 3/4 | 273. 1 | 2630 - 180 | 15 | |

WG-11.3/4 | CMS-XL11.3/4 | 11.3/4 | 298. 5 | 2627 - 204 | 17 | |

WG-13. 3/8 | CMS-XL13. 3/8 | 13. 3/8 | 339. 7 | 2630 - 216 | 18 | |

WG-16-1350 | CMS-XL16 | 16 | 406. 4 | 2631 一 252 | 21 | |

WG-18.5/8-1350 | CMS-XL18. 5/8 | 18. 5/8 | 473. 1 | 2626 - 300 | 25 | 150 |

WG-20-1350 | CMS-XL20 | 20 | 508 | 2631 - 312 | 26 | |

WG-24-1350 | CMS-XL24 | 24 | 609. 6 | 2631 - 360 | 30 | |

WG-26-1350 | CMS-XL26 | 26 | 660. 4 | 2631 一 396 | 33 | |

WG-30-1350 | CMS-XL30 | 30 | 762 | 2631 - 444 | 37 | |

UC-3 series casing slips are designed and manufactured in a structure of multi-segment pieces with firm structure, light weight and large holding range, which is easy to fit the changing of the external diameter of the casing pipes due to wear and tear. They are designed and manufactured in API Spec 7K Drilling slips.

Domestic Model | International Model | Size (in) | Inserts Qty | Slip Segment Qty | Handle Qty | Fitted Bushing Taper | Rated Capacity (short tons) |

WG-7 | 8. 5/8UC-3 | 7 | 10 | 10 | 3 | Fit4" taper | 250 |

WG-7.5/8 | 8. 5/8UC-3 | 7. 5/8 | 10 | 10 | 3 | ||

WG-8. 1/8 | 8. 5/8UC-3 | 8. 1/8 | 10 | 10 | 3 | ||

WG-8. 5/8 | 8. 5/8UC-3 | 8. 5/8 | 10 | 10 | 3 | ||

WG-9 | 10. 3/4UC-3 | 9 | 10 | 10 | 3 | Fit 3" taper | |

WG-9.5/8 | 10. 3/4UC-3 | 9. 5/8 | 10 | 10 | 3 | ||

WG-10.3/4 | 10. 3/4UC-3 | 10. 3/4 | 10 | 10 | 3 | ||

WG-11.3/4 | 11.3/4-24 UC-3 | 11.3/4 | 12 | 12 | 4 | ||

WG-12. 3/4 | 11.3/4-24 UC-3 | 12. 3/4 | 12 | 12 | 4 | ||

WG-13. 3/8 | 11.3/4-24 UC-3 | 13. 3/8 | 12 | 12 | 4 | ||

WG-16 | 11.3/4-24 UC-3 | 16 | 14 | 14 | 5 | ||

WG-18.5/8 | 11.3/4-24 UC-3 | 18. 5/8 | 17 | 17 | 5 | ||

WG-20 | 11.3/4-24 UC-3 | 20 | 17 | 17 | 5 | ||

WG-24 | 11.3/4-24 UC-3 | 24 | 19 | 19 | 5 |

Product Description:

There are three types of DCS Drill Collar Slips: S, R and L. They can accommodate drill collars from 3in(76.2mm) to 14in(355.6mm) O.D.. The handling sizes can be adjusted by changing the quantity of inserts or slip body. They are designed and manufactured according to API Spec 7K.

Product Features:

Wide Size Accommodation: DCS slips can accommodate drill collars ranging from 3 inches (76.2 mm) to 14 inches (355.6 mm) in outer diameter (OD), ensuring versatility in various drilling applications.

Adjustable Handling Sizes: The handling size of DCS slips can be easily adjusted by changing the quantity of inserts or the slip body itself, providing flexibility for different drill collar sizes.

API Spec 7K Compliance: Designed and manufactured according to API Spec 7K, DCS slips adhere to rigorous industry standards for quality, safety, and performance.

Durability: Constructed from high-quality materials, DCS slips are designed to withstand the demanding conditions of drilling operations, ensuring long-lasting durability.

Safety Features: These slips incorporate safety features such as overload protection and anti-slip mechanisms to minimize the risk of accidents and protect personnel.

Easy Handling: DCS slips are typically designed for easy handling and operation, with user-friendly features and clear markings.

Customizable Options: Depending on specific drilling needs, DCS slips can often be customized with various options, such as different sizes, materials, or features.

Type-Specific Features:

S-Type: Standard slips suitable for general drilling applications.

R-Type: Reduced-diameter slips for use in smaller-diameter wells or when space is limited.

L-Type: Longer slips designed for deeper wells or applications requiring increased gripping length.

Product Specification:

MODEL | DCS-S | DCS-R | DCS-L | ||||||||

DC OD | in | 3-4 | 4-4.7/8 | 4.1/2-6 | 5.1/2-7 | 6.3/4- | 8- | 8.1/2- | 9.1/4- | 11- | 12- |

mm | 76.2- | 101.6- | 114.3- | 139.7- | 171.4- | 203.2- | 215.9- | 235- | 279.4- | 304.8- | |

Weight | kg | 51 | 47 | 54 | 51 | 70 | 78 | 84 | 90 | 116 | 107 |

lb | 112 | 103 | 120 | 112 | 154 | 173 | 185 | 198 | 256 | 237 | |

Use in insert bowl No. | API or No.3 | No.2 | No.1 | ||||||||

Product Description:

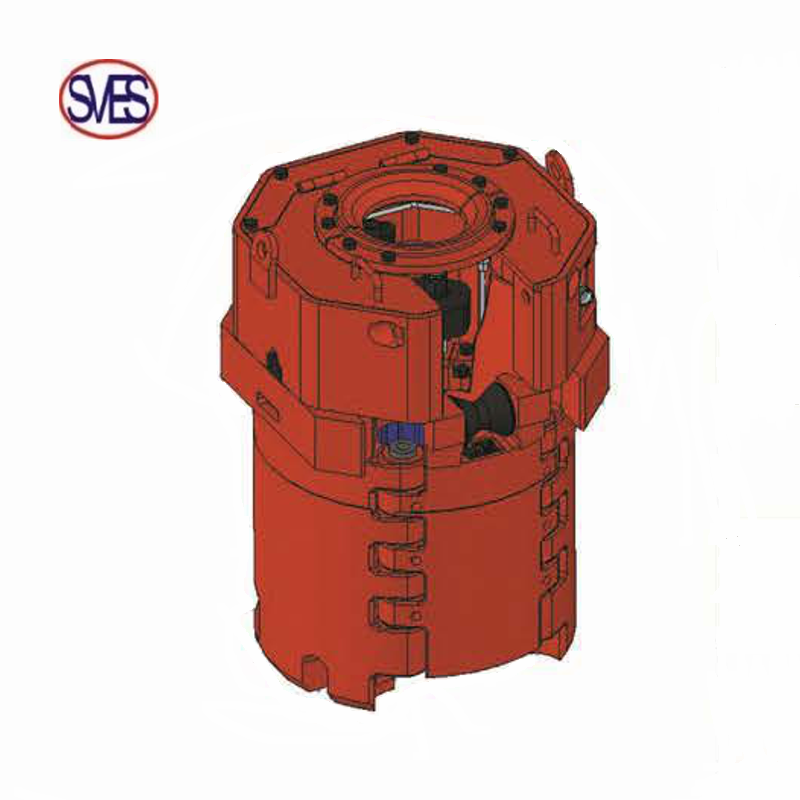

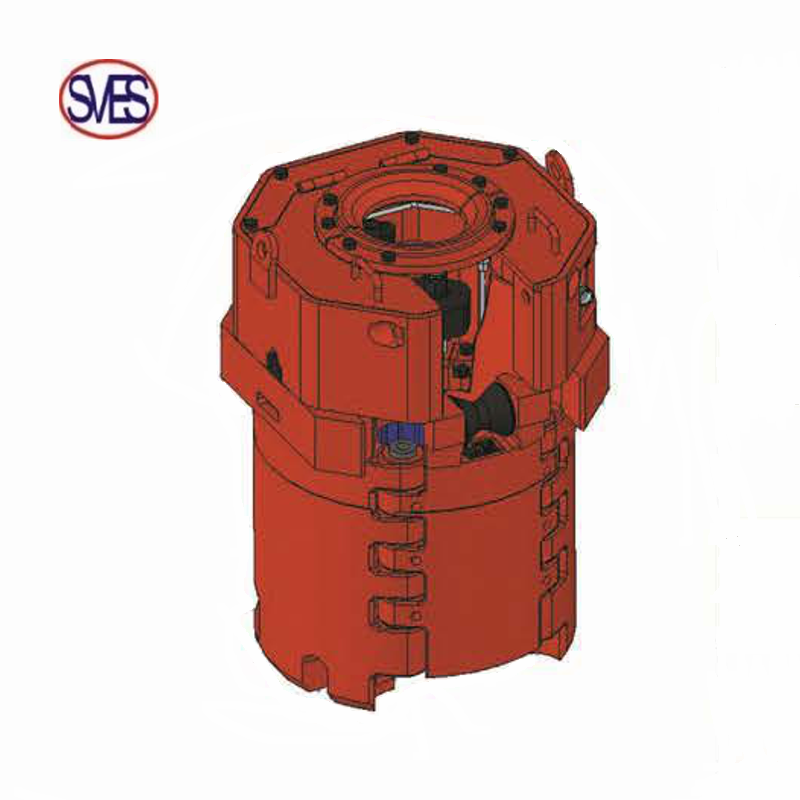

PS Series Pneumatic Slips are pneumatic tools which are suitable for all kinds of rotary tables for hoisting drill pipes and handling casings. They are mechanized operating with strong hoisting force and large working range. They are easy to operate and dependable enough. Besides, they can not only reduce the workload but also improve the work efficiency. They are designed and manufactured according to API Spec 7K.

Product Features:

PS Series Pneumatic Slips are specialized hoisting tools designed for use with rotary tables in oil and gas drilling operations. These pneumatic-powered slips offer several key advantages:

Versatility: Suitable for handling both drill pipes and casings, making them adaptable to various drilling scenarios.

Mechanized Operation: The pneumatic system provides powerful and efficient operation, reducing manual labor requirements.

Strong Hoisting Force: Capable of handling heavy loads, ensuring secure and reliable gripping of equipment.

Large Working Range: Can accommodate a wide range of pipe sizes, making them versatile for different drilling applications.

Ease of Operation: Intuitive controls and user-friendly design simplify operation, reducing the learning curve for operators.

Reliability: Pneumatic systems are known for their reliability and durability, ensuring consistent performance in demanding environments.

Improved Efficiency: By automating the lifting and lowering process, PS Series Pneumatic Slips can significantly improve work efficiency and productivity.

API Spec 7K Compliance: Designed and manufactured according to API Spec 7K, these slips adhere to industry standards for quality, safety, and performance.

Product Specificaiton:

Model | Rotary table size | Applicable diameter of tubulars (in) | Rated capacity (tons) | Work pressure (MPa) | (Max. pressure MPa) |

PS175 | 17.1/2 | 2.3/8-5.3/4 | 150 | 0.6-0.8 | 1 |

PS205 | 20.1/2 | 2.3/8-5.3/4 | 250 | 0.6-0.8 | 1 |

PS275 | 27.1/2 | 2.3/8-9.7/8 | 350 | 0.6-0.8 | 1 |

PS375 | 37.1/2 | 2.3/8-14 | 500 | 0.6-0.8 | 1 |

PS16 | 27.1/2, 37.1/2, 49.1/2, | 3.1/2-7.3/4 | 500 | 0.6-0.8 | 1 |

PS Portable | 23,27.1/2, 37.1/2, 49.1/2, | 2.3/8-5.1/2 | 250 | 0.6-0.8 | 1 |

PS slant hole | For slant hole drilling rig | 2.7/8-13.3/8 | 250 | 0.6-0.8 | 1 |

Russian style 560 | 560mm | 1.9-7 | 350 | 0.6-0.8 | 1 |

Product Description:

Type A drill collar slips (Woolley Style) are multi-segments slips. They can accommodate the changes of outer diameter after the abrasion of drill collar. They are with light weight,large handling scale and reliable quality.This kind of slips are designed and manufactured according to API Spec 7K Specification for drill and well servicing equipment.

Product Features:

Type A Drill Collar Slips (Woolley Style) are specialized hoisting tools designed for handling drill collars during drilling operations. These slips offer several key features:

Multi-Segment Design: The multi-segment design allows for easy adjustment of the slip's gripping diameter, ensuring compatibility with various drill collar sizes.

Accommodates Wear and Tear: These slips can accommodate changes in the outer diameter of the drill collar due to abrasion, providing a secure grip even after prolonged use.

Lightweight Construction: Designed to be lightweight, reducing the overall weight of the drilling string and improving efficiency.

Large Handling Scale: Can handle a wide range of drill collar sizes, making them versatile for different drilling applications.

Reliable Quality: Manufactured to high standards, ensuring durability and performance in demanding drilling environments.

API Spec 7K Compliance: Adheres to API Spec 7K standards for quality, safety, and performance.

Product Specification:

Slip Type | Drill Collar OD | Insert Bowl No. | |

in | mm | ||

Model A | 3-4 1/2 | 76.2-114.3 | API or No.3 |

3 1/4-3 3/4 | 82.55-120.65 | ||

4 1/4-5 3/4 | 107.95-146.05 | ||

5 1/2-7 | 139.7-177.8 | ||

6 3/4-8 1/4 | 171.5-209.55 | ||

8 1/4-10 | 209.55-254 | No.2 | |

10-11 3/4 | 254-298.45 | ||

Product Description:

There are three model of type B rotary slips(woolley style):B short,B Long and X Long.

The unique torque transmitting design can directly transfer all the torque to the slips,avoiding the abrasion,prolonging the service life.The product is designed and manufactured according to API Spec 7K requirements.

Product Features:

Type B Rotary Slips (Woolley Style) are specialized hoisting tools designed for use in oil and gas drilling operations. These slips offer several key features:

Three Model Options: Available in three models: B Short, B Long, and X Long, to accommodate different drilling depths and requirements.

Unique Torque Transmission: The slips' design directly transmits torque, reducing wear and tear on the slips themselves and extending their service life.

Durability: Constructed from high-quality materials, ensuring long-lasting performance and resistance to wear and tear.

API Spec 7K Compliance: Manufactured according to API Spec 7K standards, guaranteeing quality, safety, and performance.

Product Specification:

Model | Size of Slip bodies | Depth of well(feet) | |||||

4 1/2 | 5 1/2 | 5 | |||||

DP OD | DP OD | DP OD | |||||

in | mm | in | mm | in | mm | ||

B Short(B-S) | 2 3/8 | 60.3 | / | / | / | / | 8000 |

2 7/8 | 73 | / | / | / | / | ||

3 1/2 | 88.9 | / | / | / | / | ||

4 | 101.6 | / | / | / | / | ||

4 1/2 | 114.3 | / | / | / | / | ||

B Long(B-L) | 2 3/8 | 60.3 | 4 | 101.6 | / | / | 18000 |

2 7/8 | 73 | 4 1/2 | 114.3 | / | / | ||

3 1/2 | 88.9 | 5 | 127 | / | / | ||

4 | 101.6 | 5 1/2 | 139.7 | / | / | ||

4 1/2 | 114.3 | / | / | / | / | ||

X Long(B-XL) | 3 1/2 | 88.9 | / | / | 4 | 101.6 | 28500 |

4 | 101.6 | / | / | 4 1/2 | 114.3 | ||

4 1/2 | 114.3 | / | / | 5 | 127 | ||

Product Description:

There are three types of DU Series Rotary Slips: DU, DUL and SDU. They are with large handling range and light weight. Therefore, these slips have larger contact area on the taper and heat-treated for strength and wear resistance. They are designed and manufactured according to API Spec 7K.

Product Features:

DU Series Rotary Slips are specialized hoisting tools designed for use in oil and gas drilling operations. These slips offer several key features:

Three Model Options: Available in three models: DU, DUL, and SDU, to accommodate different drilling needs.

Large Handling Range: Can handle a wide range of drill pipe and casing sizes, ensuring versatility in various applications.

Lightweight Construction: Designed to be lightweight, reducing the overall weight of the drilling string and improving efficiency.

Increased Contact Area: The slips have a larger contact area on the taper, providing a more secure grip and reducing wear and tear.

Heat-Treated for Strength: Constructed from heat-treated materials, ensuring durability and resistance to harsh drilling conditions.

API Spec 7K Compliance: Manufactured according to API Spec 7K standards, guaranteeing quality, safety, and performance.

Product Specification:

Model | Size of Slip bodies | 4.1/2 | |||||

DU | DP OD | in | 2.3/8 | 2.7/8 | 3.1/2 | 4 | 4.1/2 |

mm | 60.3 | 73.0 | 88.9 | 101.6 | 114.3 | ||

DUL | DP OD | in | 2.3/8 | 2.7/8 | 3.1/2 | 4 | 4.1/2 |

mm | 60.3 | 73.0 | 88.9 | 101.6 | 114.3 | ||

SDU | DP OD | in | — | — | — | — | — |

mm | — | — | — | — | — | ||

Model | Size of Slip bodies | 5.1/2 | |||||

DU | DP OD | in | 3.1/2 | 4 | 4.1/2 | 5 | 5.1/2 |

mm | 88.9 | 101.6 | 114.3 | 127 | 139.7 | ||

DUL | DP OD | in | 3.1/2 | 4 | 4.1/2 | 5 | 5.1/2 |

mm | 88.9 | 101.6 | 114.3 | 127 | 139.7 | ||

SDU | DP OD | in | 3.1/2 | 4 | 4.1/2 | 5 | 5.1/2 |

mm | 88.9 | 101.6 | 114.3 | 127 | 139.7 | ||

Model | Size of Slip bodies | 7 | |||||

DU | DP OD | in | 4.1/2 | 5 | 5.1/2 | 6.5/8 | 7 |

mm | 114.3 | 127 | 139.7 | 168.3 | 177.8 | ||

DUL | DP OD | in | — | — | — | — | — |

mm | — | — | — | — | — | ||

SDU | DP OD | in | 4.1/2 | 5 | 5.1/2 | 6.5/8 | 7 |

mm | 114.3 | 127 | 139.7 | 168.3 | 177.8 | ||

Product Description:

The products are designed and manufactured according to API Spec 7K Specification for drilling and well servicing equipment.Flake Rotary Slips have three segments.They can handle various O.D. Drill pipes,drill collars and casings by changing inserts or insert bowls. There are two types of such slips:W3 1/2-5 /100 and W5-7 /100.

Product Features:

Flake Rotary Slips are specialized hoisting tools designed for use in oil and gas drilling operations. These slips offer several key features:

Three-Segment Design: The multi-segment design allows for easy adjustment of the slip's gripping diameter, ensuring compatibility with various drill pipe, drill collar, and casing sizes.

Wide Size Accommodation: Can handle a wide range of outer diameters (OD), making them versatile for different drilling applications.

Insert Customization: The ability to change inserts or insert bowls allows for further customization of the slip's gripping diameter.

Two Available Types: Offered in two types: W3 1/2-5 /100 and W5-7 /100, catering to different drilling needs.

API Spec 7K Compliance: Manufactured according to API Spec 7K standards, guaranteeing quality, safety, and performance.

Product Sepcifications:

| Mode | W31/2-5/100 | W5-7/100 | Max Load (KN) | ||

| in | mm | in | mm | ||

| Size of Tubulars | 27/8 | 73.03 | 5 | 127 | 1000 |

| 31/2 | 88.9 | 51/2 | 139.7 | ||

| 4 | 101.6 | 59/16 | 141.3 | ||

| 41/8 | 104.8 | 53/4 | 146.1 | ||

| 41/2 | 114.3 | 61/8 | 155.6 | ||

| 41/4 | 120.7 | 61/4 | 158.8 | ||

| 5 | 127 | 61/2 | 165.1 | ||

| / | / | 65/8 | 168.3 | ||

| / | / | 7 | 177.8 | ||

Product Description:

Type WT Drill Collar Slips can accommodate drill collars from 4 1/2”(114.3mm) to 9 1/2”(241.3mm)OD.

Type WT Drill Collar Slips are designed and manufactured according to API SPEC 7K Specification for drilling and well servicing equipments.

Product Features:

Multi-Segment Design: Allows for easy adjustment of the gripping diameter to accommodate various drill collar sizes.

Wide Size Accommodation: Handles a wide range of drill collar outer diameters (OD), offering versatility for different drilling projects.

Durability: Constructed from high-quality materials to withstand demanding drilling conditions.

API Spec 7K Compliance: Manufactured according to industry standards, guaranteeing quality, safety, and performance.

Reliability: Known for their reliable and consistent performance in challenging drilling environments.

Ease of Handling: Typically designed for user-friendly operation with clear markings.

Product Specification:

Model | WT 4 1/2-6 | WT 5 1/2-7 | WT 6 3/4-8 1/4 | WT 8-9 1/2 | |

Drill Collar OD | in | 4 1/2-6 | 5 1/2-7 | 6 3/4-8 1/4 | 8-9 1/2 |

mm | 114.3-152.4 | 139.7-177.8 | 171.4-209.6 | 203.2-241.3 | |

weight | kg | 49 | 46 | 42 | 39 |

lb | 108 | 101 | 92 | 86 | |

Use in Insert Bowl No. |

| API or No.3 | |||

Max.Load |

| 40 short tons | |||