- Home

- >

- Products

- >

- Pneumatic Spider

- >

Pneumatic Spider

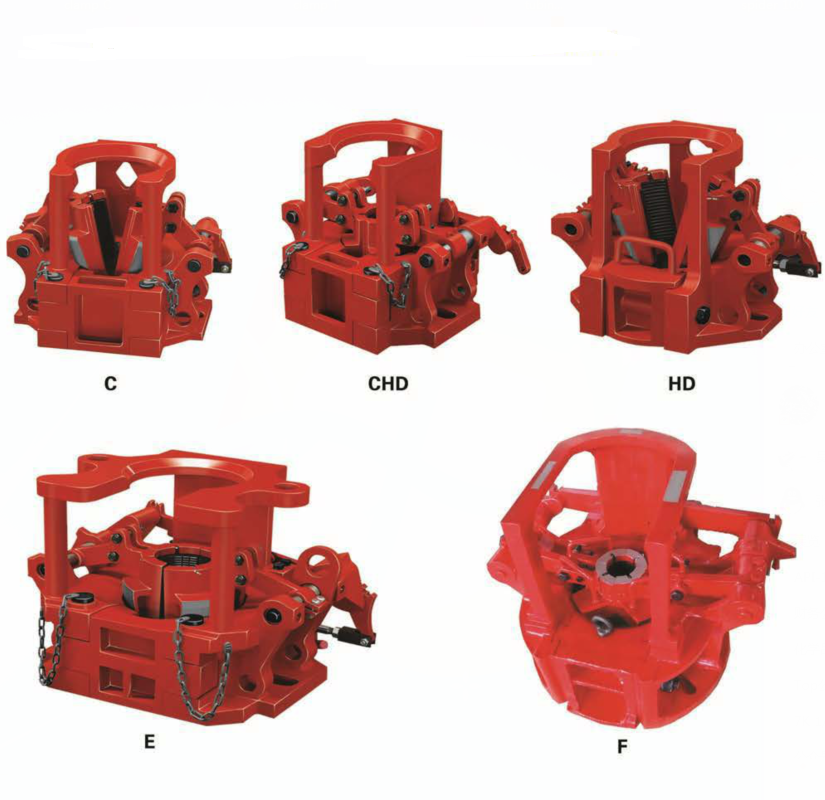

Model | Size of slip body | (in) Gripping diameter of pipe | Rated load (short tons) | Model | Size of slip body | (in) .Gripping . diameter ofpipe | Rated load (short tons) |

C | 3. 1/2 | 1.315 | 80 | HD | 3. 1/2 | 2. 06 | 125 |

1. 66 | 80 | 2. 3/8 | |||||

1. 90 | 80 | ||||||

2. 5 | |||||||

2. 06 | 80 | ||||||

2. 7/8 | |||||||

2. 3/8 | 80 | ||||||

3. 125 | |||||||

2. 5 | 80 | ||||||

2. 7/8 | 80 | 3. 1/2 | |||||

3. 125 | 80 | 4. 1/2 | 3. 1/2 | ||||

3. 1/2 | 80 | 4 | |||||

4. 1/2 | 3. 1/2 | 80 | 4. 1/2 | ||||

4 | 80 | 4. 3/4 Integrated type | 4. 3/4 | ||||

4. 1/2 | 80 | ||||||

5 Integrated type | 5 | ||||||

4. 3/4 ( Integrated type) | 4. 3/4 | 80 | |||||

5. 1/2 Integrated type | 5. 1/2 | ||||||

5 Integrated type | 5 | 80 | |||||

E | 3. 1/2 | 2. 3/8 | 175 | ||||

5. 1/2 Integrated type | 5. 1/2 | 80 | |||||

2. 7/8 | |||||||

CHD | 3. 1/2 | 1.315 | 120 | ||||

1. 66 | 120 | 3. 1/2 | |||||

1. 90 | 120 | 5. 1/2 | 4 | ||||

4. 1/2 | |||||||

2. 06 | 120 | ||||||

5 | |||||||

2. 3/8 | 120 | ||||||

5. 1/2 | |||||||

2. 5 | 120 | 7 | 5. 1/2 | ||||

6. 5/8 | |||||||

2. 7/8 | 120 | ||||||

7 | |||||||

3. 125 | 120 | ||||||

7. 5/8 Integrated type | 7. 5/8 | ||||||

3. 1/2 | 120 | F | 3. 1/2 | 2. 3/8 | 200 | ||

4. 1/2 | 3. 1/2 | 120 | 2. 7/8 | ||||

3. 1/2 | |||||||

4 | 120 | ||||||

5. 1/2 | 4 | ||||||

4. 1/2 | 120 | ||||||

4. 1/2 | |||||||

4. 3/4 Integrated type | 4. 3/4 | 120 | |||||

5 | |||||||

5 Integrated type | 5 | 120 | 5. 1/2 | ||||

5. 1/2 Integrated type | 5. 1/2 | 120 | 7. 5/8 | 6. 5/8 | |||

HD | 3. 1/2 | 1.315 | 125 | 7 | |||

1. 66 | 125 | 7. 5/8 | |||||

1. 90 | 125 | 8. 5/8 Integrated type | 8. 5/8 |

QQP pneumatic spiders are suitable for gripping drill pipes and tubing during oilfield drilling and workover operations. The product is designed and manufactured in accordance with API Spec 7K Specification.

Model | Size of slip body | (in) Applicable pipe size | Rated load (short tons) |

QQP/75 | 2. 7/8 | 2. 3/8 | 75 |

2. 7/8 | |||

3. 1/2 | 3. 1/2 | ||

QQP/100 | 2. 7/8 | 1.9 | 100 |

2 | |||

2. 3/8 | |||

2. 1/2 | |||

2. 7/8 | |||

3 | |||

3. 1/2 | 3. 1/2 | ||

4. 1/2 | 4 | ||

4. 1/8 | |||

4. 1/2 | |||

5 | 4. 3/4 | ||

5 | |||

QP30(3. 1/2) | 3. 1/2 | 2. 7/8 | 30 |

3. 1/2 | |||

QP30(4. 1/2) | (114. 3) | (55. 5 mm ) | 30 |

(69. 9 mm) | |||

(88. 9 mm) | |||

(114. 3 mm ) |

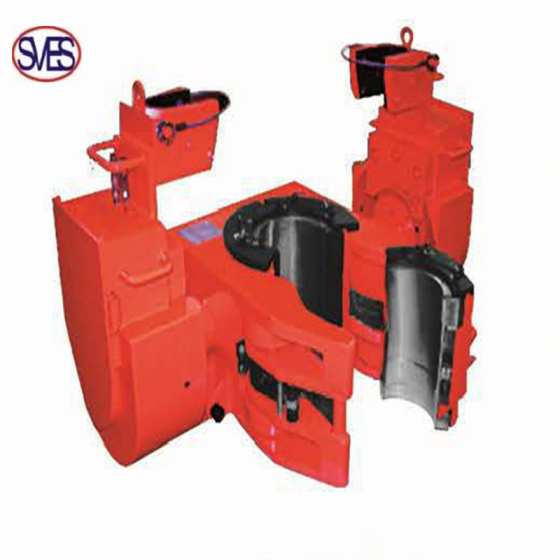

TS-100 tubing spiders are suitable for gripping drill collar, polish drill string, casing, tubing and polish tools, and the spider body and the slip are both made by alloy steel through special heat treatment. It is light and easy for operation. The product is designed and manufactured in accordance with API Spec 7K Specification.

| Model | (in) Applicable pipe size | Rated load (short tons) | Model | (in) Applicable pipe size | Rated load (short tons) |

| TS3. 1/2-100 | 1.05 | 100 | TS5. 1/2-100 | 3 | 100 |

| 1.315 | 100 | 3. 1/8 | 100 | ||

| 1. 66 | 100 | 3. 1/4 | 100 | ||

| 1.9 | 100 | 3. 1/2 | 100 | ||

| TS3. 1/2-100 | 2 | 100 | 3. 3/4 | 100 | |

| 2. 1/16 | 100 | TS5.1/2-100 | 4 | 100 | |

| 2. 3/8 | 100 | 4. 1/8 | 100 | ||

| 2. 7/8 | 100 | 4. 1/4 | 100 | ||

| TS3.1/2-100 | 3. 1/8 | 100 | 4. 3/8 | 100 | |

| 3.3/8 | 100 | 4. 1/2 | 100 | ||

| 3. 1/2 | 100 | TS5.1/2-100 | 4. 3/4 | 100 | |

| TS5.1/2-100 | 2. 3/8 | 100 | 5 | 100 | |

| 2. 7/8 | 100 | 5. 1/2 | 100 | ||

| 5. 3/4 | 100 |

Product Description:

There are three types of DCS Drill Collar Slips: S, R and L. They can accommodate drill collars from 3in(76.2mm) to 14in(355.6mm) O.D.. The handling sizes can be adjusted by changing the quantity of inserts or slip body. They are designed and manufactured according to API Spec 7K.

Product Features:

Wide Size Accommodation: DCS slips can accommodate drill collars ranging from 3 inches (76.2 mm) to 14 inches (355.6 mm) in outer diameter (OD), ensuring versatility in various drilling applications.

Adjustable Handling Sizes: The handling size of DCS slips can be easily adjusted by changing the quantity of inserts or the slip body itself, providing flexibility for different drill collar sizes.

API Spec 7K Compliance: Designed and manufactured according to API Spec 7K, DCS slips adhere to rigorous industry standards for quality, safety, and performance.

Durability: Constructed from high-quality materials, DCS slips are designed to withstand the demanding conditions of drilling operations, ensuring long-lasting durability.

Safety Features: These slips incorporate safety features such as overload protection and anti-slip mechanisms to minimize the risk of accidents and protect personnel.

Easy Handling: DCS slips are typically designed for easy handling and operation, with user-friendly features and clear markings.

Customizable Options: Depending on specific drilling needs, DCS slips can often be customized with various options, such as different sizes, materials, or features.

Type-Specific Features:

S-Type: Standard slips suitable for general drilling applications.

R-Type: Reduced-diameter slips for use in smaller-diameter wells or when space is limited.

L-Type: Longer slips designed for deeper wells or applications requiring increased gripping length.

Product Specification:

MODEL | DCS-S | DCS-R | DCS-L | ||||||||

DC OD | in | 3-4 | 4-4.7/8 | 4.1/2-6 | 5.1/2-7 | 6.3/4- | 8- | 8.1/2- | 9.1/4- | 11- | 12- |

mm | 76.2- | 101.6- | 114.3- | 139.7- | 171.4- | 203.2- | 215.9- | 235- | 279.4- | 304.8- | |

Weight | kg | 51 | 47 | 54 | 51 | 70 | 78 | 84 | 90 | 116 | 107 |

lb | 112 | 103 | 120 | 112 | 154 | 173 | 185 | 198 | 256 | 237 | |

Use in insert bowl No. | API or No.3 | No.2 | No.1 | ||||||||