- Home

- >

- Products

- >

- Manual Tongs

- >

Manual Tongs

Lug Jaw No. | Steps | Size Range(in) | Rated Torque (kN ・ m) | |

in | mm | |||

1# | 1 | 2. 3/8〜2. 7/8 | 60.32〜73 | 22 |

2 | 2. 7/8〜3.1/2 | 73〜88. 9 | ||

2# | 1 | 3.1/2-4. 1/4 | 88.9-107. 95 | |

2 | 4.1/4 〜5 | 107. 95〜127 | ||

3# | 1 | 4. 3/4〜5. 1/2 | 120. 65〜139. 7 | |

2 | 5. 1/2-6. 1/4 | 139.7〜158. 75 | ||

4# | 1 | 5. 3/4〜6. 3/8 | 146.05〜161.93 | |

2 | 6. 3/8〜7 | 161.93〜177. 8 | ||

Lug Jaw No. | Size Range | Rated Torque (kN • m) | |

in | mm | ||

1 # | 2. 7/8〜3. 3/4 | 73〜95. 25 | 75 |

2# | 3. 1/2—4. 1/2 | 88. 9〜114. 3 | |

3# | 4 〜5. 1/4 | 101.6〜133. 35 | |

4# | 5 〜7. 1/4 | 127 〜184. 15 | |

5# | 6. 7/8〜8. 5/8 | 174. 6〜219. 1 | |

6# | 9〜10. 3/4 | 228. 6〜273. 05 | 40 |

7# | 10.3/4〜11. 3/4 | 273. 05〜298. 45 | |

8# | 13. 3/8 | 339. 7 | |

Q13.3/8/8 Casing Tongs Q13.3/8/8

Lug Jaw No. | Size Range | Rated Torque (kN • m) | |

in | mm | ||

4# | 13. 3/8 | 340、 365 (Casing coupling dimension) | 8 |

Extended Casing Tong Q13.3/8 ~ 25.1/2/35

Model | Hinge Jaw No. | Size Range | Rated Torque (kN • m) | |

in | mm | |||

Q13.3/8〜25.1/2/35 | 9、8 | 13. 3/8〜14. 1/2 | 340〜368. 3 | 35 |

8、7 | 14.1/2〜16 | 368. 3〜406. 4 | ||

8、9、9 | 16 〜17. 1/2 | 406. 4—444. 5 | ||

8、9、7 | 17. 1/2 〜19 | 444. 5〜482. 6 | ||

7、8、7 | 19 〜20 | 482. 6 — 508 | ||

9、 8、 9、 7 | 20〜21. 1/2 | 508—546. 1 | ||

9、 7、 8、 7 | 21.1/2〜23 | 546. 1 〜584. 2 | ||

9、 9、 8、 7、 7 | 24〜25. 1/2 | 609. 6〜647. 7 | ||

9、 8、 7、 7、 7 | 25. 1/2 〜27 | 647. 7—685. 8 | ||

8、 7、 7、 7、 7 | 27 〜28. 1/2 | 685. 8〜723. 9 | ||

9、9、8、7、7、8 | 28.1/2〜30 | 723. 9—762 | ||

9、7、7、7、7、8 | 30 | 762 | ||

Q25. 3/8〜36/35 | 9、 8、 7、 7、 7 | 25. 1/2 〜27 | 647. 7—685. 8 | 35 |

8、 7、 7、 7、 7 | 27 〜28. 1/2 | 685. 8〜723. 9 | ||

9、9、7、7、7、8 | 28.1/2〜30 | 723. 9—762 | ||

9、7、7、7、7、8 | 30〜31.5/8 | 762—803. 3 | ||

8、 9、 8、 9、 7、 7、 7 | 31.1/2〜33 | 800. 1—838.2 | ||

7、9、8、9、9、7、8、9 | 33〜34. 1/2 | 838. 2—876. 3 | ||

8、7、7、9、9、8、8、8 | 34. 1/2 〜36 | 876. 3〜914. 4 | ||

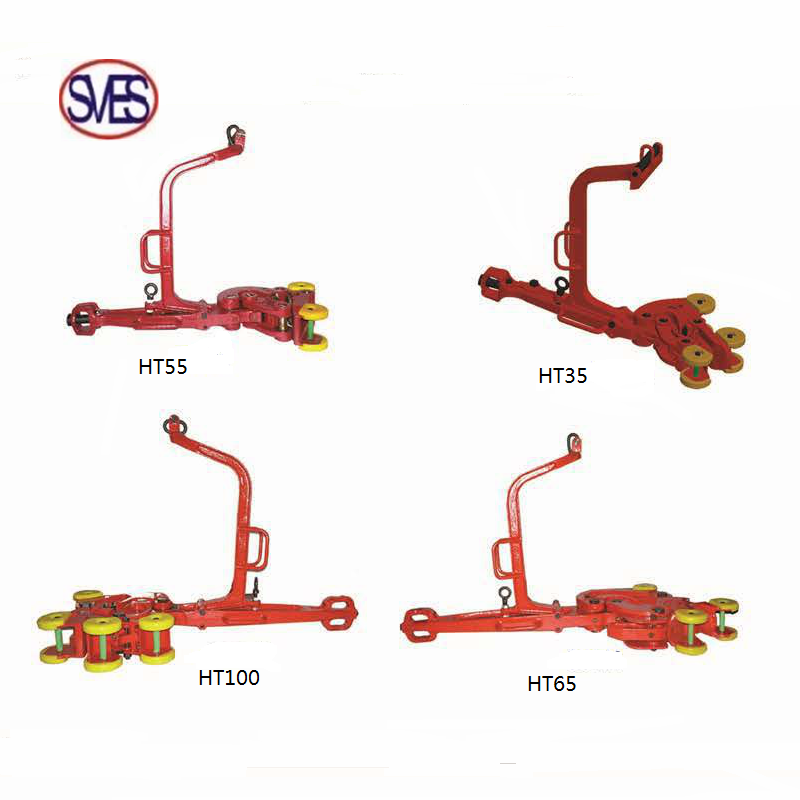

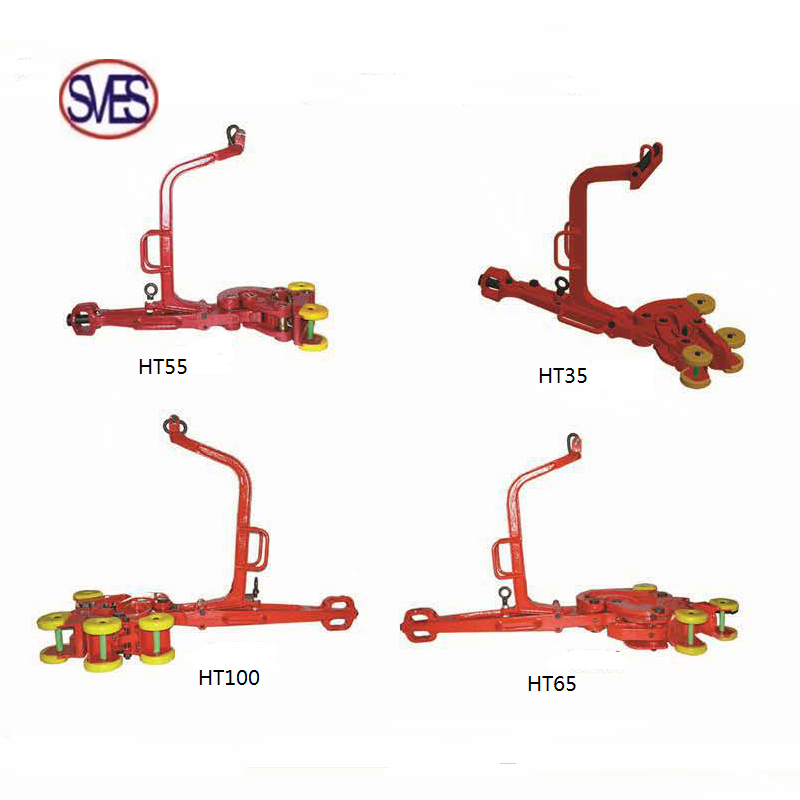

Q2.3/8 ~ 10.3/4/48 HT35 Manual Tongs

Lug Jaw No. | Short Jaw No. | Hinge Jaw No. | Size Range | Rated Torque (kN - m) | |

in | mm | ||||

1祥 | 1 # | / | 2. 3/8〜3. 668 | 60. 33〜93. 17 | 20 |

2# | 1 # | / | 2. 7/8〜4. 1/4 | 73. 03〜108 | |

3# | 1 # | / | 3. 1/2 〜5. 1/4 | 88. 9〜133. 35 | 34 |

4# | 1 # | / | 5. 1/4—7 | 133. 35 — 177. 8 | 48 |

5# | 2# | 1 # | 7 〜8. 5/8 | 177. 8〜219. 08 | 34 |

6# | 2# | 2# | 9. 5/8 〜10. 3/4 | 244. 5—273. 05 | 43 |

Q3.1/2 ~ 13.3/8/75 HT55 Manual Tongs

Lug Jaw No. | Latch Step | Size Range | Rated Torque (kN ・ m) | |

in | mm | |||

1 # | 1 | 3. 1/2—4. 1/8 | 88.9—104. 78 | 48 |

2 | 4. 1/8 〜5 | 104. 78〜127 | ||

2# | 1 | 5〜5. 3/4 | 127 〜146. 05 | 75 |

2 | 6〜6. 3/4 | 152. 4—171.45 | ||

3# | 1 | 6. 5/8〜7. 1/4 | 168. 28〜184. 15 | |

2 | 7. 3/8〜8 | 187. 33〜203. 2 | ||

3 | 8. 1/2 — 9 | 215. 9〜228. 6 | ||

4# | 1 | 9 〜9. 5/8 | 228. 6〜244. 48 | 55 |

2 | 10. 5/8 〜10. 3/4 | 269. 88〜273. 05 | ||

5# | 1 | 11.3/4 | 298.45 | 40 |

6# | 1 | 12. 3/4〜13 | 323. 85〜330. 2 | |

7# | 1 | 13.3/8 | 339. 73 | |

Q13.3/8 ~ 25.1/2/68 HT50 Manual Tongs

Hinge Jaw No. | Size Range | Rated Torque (kN - m) | |

in | mm | ||

8、9 | 13. 3/8〜14. 1/2 | 339. 73〜368. 3 | 68 |

7、8 | 14. 1/2 〜16 | 368. 3〜406. 4 | |

8、9、9 | 16 〜17. 1/2 | 406. 4〜444. 5 | |

7、8、9 | 17. 1/2 〜19 | 444. 5〜482. 6 | |

7、7、8 | 19 〜20 | 482. 6 — 508 | |

7、 8、 9、 9 | 20 〜21. 1/2 | 508 〜546. 1 | |

7、 7、 8、 9 | 21.1/2〜23 | 546. 1—584. 2 | |

7、 7、 8、 9、 9 | 24 〜25. 1/2 | 609. 6〜647. 7 | |

Q3.1/2 ~ 17/90 HT65 Manual Tongs

Lug Jaw No. | Hinge Pin Hole | Size Range | Rated Torque (kN ・ m) | |

in | mm | |||

1 # | 1 | 3. 1/2 〜6 | 88. 9~152 | 90 |

II | 4. 1/2 〜7 | 114. 3〜177. 8 | ||

III | 5. 1/2 — 8. 1/4 | 139. 7〜209. 55 | ||

2# | I | 8 〜9. 5/8 | 203. 2〜244. 48 | |

II | 9. 5/8〜11. 1/4 | 244. 48〜285. 75 | ||

3# | I | 11.3/4〜12. 3/4 | 298. 45〜323. 85 | 55 |

II | 13. 3/8〜14. 3/8 | 339. 73〜365. 73 | ||

4# | II | 16 〜17 | 406. 4 — 431.8 | |

Q4 ~ 17/135 HT100 Manual Tongs

Lug Jaw No. | Hinge Pin Hole | Size Range | Rated Torque (kN • m) | ||

in | mm | ||||

1 # | 1 | / | 4〜5. 3/4 | 101.6—146. 05 | 135 |

2 | / | 5. 1/2 〜7. 1/4 | 139. 7〜〔84.15 | ||

3 | / | 6. 5/8〜8. 1/2 | 168. 27〜215. 9 | ||

2# | 1 | 8. 1/2〜10. 3/4 | 215.9—273. 05 | ||

2 | 10. 3/4〜12 | 273. 05—304. 8 | |||

3# | 1 | 12〜12. 3/4 | 304. 8〜323. 85 | 100 | |

2 | 13. 3/8〜15 | 339. 7〜381 | |||

4# | 2 | 15. 3/4 | 400. 05 | 80 | |

5# | 2 | 16 〜17 | 406. 4—431.8 | ||

Product Description

Type SDD Manual Tong is an essential tool in oil drilling operation to make-up and break-out the drill pipe, casing joint and coupling.

SDD Manual Tong can be adjusted by changing latch lug jaws and handling shoulders. All the tongs we offer are API 7K & ISO certificated.

Product Specification

SDD Manual Tongs

| No.of Lug | Latch Jaws | No.of Pin | Hinge Hole | Size Range | Rated Torque | |

| in | mm | KN ·m | ||||

| 1# | 1 | 4-5 1/2 | 101.6-139.7 | 140 | ||

| 5 1/2-5 3/4 | 139.7-146 | |||||

| 2 | 5 1/2-6 5/8 | 139.7-168.3 | ||||

| 6 1/2-7 1/4 | 165.1-184.2 | |||||

| 2 | 6 5/8-7 5/8 | 168.3-193.7 | ||||

| 7 3/4-8 1/2 | 196.9-215.9 | |||||

| 2# | 1 | 8 1/2-9 | 215.9-228.6 | |||

| 9 1/2-10 3/4 | 241.3-273 | |||||

| 2 | 10 3/4-12 | 273-304.8 | ||||

| 3# | 1 | 12-12 3/4 | 304.8-323.8 | 100 | ||

| 2 | 13 3/8-14 | 339.7-355.6 | ||||

| 15 | 381 | |||||

| 4# | 2 | 1900/1 | 400 | 80 | ||

| 5# | 2 | 16 | 406.4 | |||

| 17 | 431.8 | |||||

Type B Manual Tongs (BJ Type B Tongs)

Product Description

Type B Manual Tongs (BJ Type B Tongs) are crucial tools in the oil and gas industry, specifically designed for operations involving the make-up (assembly) and break-out (disassembly) of drill pipes, casing joints, and couplings. These manual tongs are engineered to provide a secure grip and precise control, enabling operators to handle the high-torque requirements typical of drilling applications efficiently. The Type B Tongs are versatile and adjustable, making them suitable for a wide range of pipe sizes and types.

Features:

A key feature of the Type B Manual Tongs is their adaptability, achieved through the interchangeable latch lug jaws and handling shoulders, allowing for quick adjustments to accommodate different pipe diameters. This flexibility enhances operational efficiency by minimizing the need for multiple tools and reducing time spent on tool changes. Additionally, the robust construction of the tongs ensures durability and reliability in demanding drilling environments, whether onshore or offshore.

All Type B Manual Tongs offered are certified to meet API 7K and ISO standards, guaranteeing compliance with the highest industry specifications for quality, safety, and performance. These certifications ensure that the tongs meet the rigorous demands of modern drilling operations, providing assurance to operators that they are using equipment designed to withstand the harsh conditions encountered in oilfield operations.

Specificaiton:

With their reliable performance, adaptability, and compliance with industry standards, Type B Manual Tongs are an essential choice for oil and gas professionals seeking dependable tools to handle critical tasks in drilling operations.

| No.of Latch Lug Jaws | Latch Step | Size Range | Rated Torque | |

| in | mm | KN-m | ||

| 5a | 1 | 3 3/8-4 1/8 | 86-105 | 55 |

| 2 | 4 1/8-5 1/4 | 105-133 | 75 | |

| 5b | 1 | 4 1/4-5 1/4 | 108-133 | 75 |

| 2 | 5-5 3/4 | 127-146 | ||

| 3 | 6-6 3/4 | 152-171 | ||

| 5b-1 | 1 | 5 1/4-5 3/4 | 133-146 | 75 |

| 2 | 6-6 5/8 | 152-168 | ||

| 3 | 6 3/4-8 | 171-203 | 55 | |

| 5c | 1 | 6 5/8-7 3/8 | 168-187 | 75 |

| 2 | 7 3/8-8 | 187-203 | ||

| 3 | 8 1/2-8 5/8 | 216-219 | 55 | |

| 5d | 1 | 8 1/2-9 5/8 | 216-244 | 55 |

| 2 | 10 5/8-10 3/4 | 270-273 | ||

| 5e | 1 | 10 3/4 | 298 | 55 |

| 2 | 12 3/4 | 324 | ||

| 5f | 1 | 13 3/8 | 340 | 55 |

Product Description:

The Type Q60-273/48 (2 3/8-10 3/4 in) C Manual Tong is a vital tool in oil and gas drilling operations, specifically designed to securely fasten or remove the screws of drill pipes, casing joints, and couplings. Its primary function is to provide the necessary torque to make up or break out these components, ensuring a safe and efficient operation. Suitable for a wide range of pipe sizes from 2 3/8 inches to 10 3/4 inches, this manual tong is highly versatile, making it an essential tool for a variety of drilling tasks.

Features:

One of the key features of the Type C Manual Tong is its adjustable design, which allows operators to change the latch lug jaws and latch steps easily. This adjustability ensures a perfect fit for different pipe sizes, providing a secure grip and reducing slippage during operation. The flexibility to accommodate various pipe diameters enhances operational efficiency by minimizing downtime associated with tool changes and adjustments, thereby improving overall productivity on the rig.

Constructed from high-strength materials, the Type Q60-273/48 C Manual Tong is built to withstand the demanding conditions typical of drilling operations, including exposure to high torque, pressure, and extreme environments. Its durable design ensures longevity and reliable performance, even under the most challenging conditions, providing peace of mind to operators and rig crews.

Specification:

Designed in compliance with industry standards, the Type C Manual Tong is a reliable and efficient choice for drilling professionals seeking a high-quality tool for managing the make-up and break-out processes. Its user-friendly design and adaptability make it an invaluable asset on any drilling rig, contributing to safer and more efficient operations.

| No.of Latch Lug Jaws | Short Jaw | Hinge Jaw | Size Range | Rated Torque | ||

| in | mm | lb ·ft | kN ·m | |||

| 1# | 2.3/8-7 | / | 2.3/8-3.668 | 60.33-93.17 | 15,000 | 20 |

| 2# | 2.7/8-4.1/4 | 73.03-108 | ||||

| 3# | 3.1/2-5.1/4 | 88.9-133.35 | 25,000 | 35 | ||

| 4# | 5.1/4-7 | 133.35-177.8 | 35,000 | 48 | ||

| 5# | 7.5/8-10.3/4 | 1# | 7-8.5/8 | 177.8-219.08 | 25,000 | 35 |

| 6# | 2# | 9.5/8-10.3/4 | 244.5-273.05 | 32,000 | 44 | |

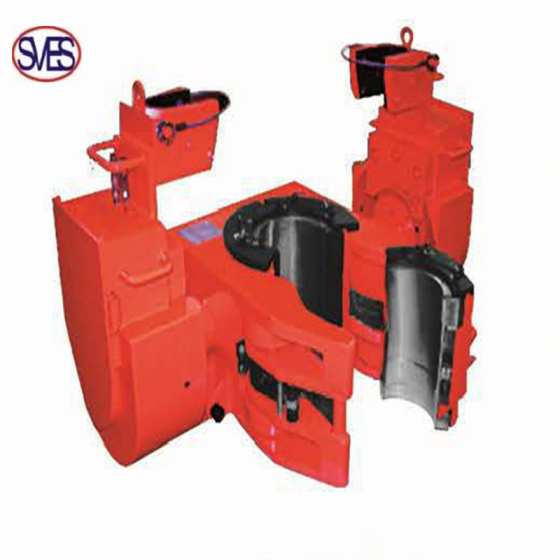

Type DB Manual Tong(BJ Type Tong)

Product Description:

The Type DB Manual Tongs (BJ Type Tongs) are heavy-duty tools designed for essential operations in oil and gas drilling, such as making up (tightening) and breaking out (loosening) drill pipes, casing joints, and couplings. Renowned for their reliability and durability, these tongs are integral to ensuring secure and efficient connections in a variety of wellbore environments.

The Type DB Manual Tongs (BJ Type Tongs) are a critical component for efficient and safe operations in the oil and gas industry, providing a reliable solution for connecting and disconnecting drill pipes, casings, and other downhole tools.

Features:

Adjustable Handling Range:The Type DB Manual Tongs are versatile, allowing adjustment to accommodate different pipe sizes by changing the latch lug jaws and handling shoulders. This adaptability makes them suitable for use with various types of drill pipes, casings, and couplings, ensuring flexibility in operations.

High Torque Capacity:Designed to handle the high torque demands of modern drilling operations, these tongs provide the necessary force to securely make up and break out connections without damaging the threads or compromising the integrity of the tubulars.

Robust Construction:Made from high-quality, heat-treated alloy steel, Type DB Manual Tongs are built to withstand the harsh conditions of drilling operations, including exposure to high stress, abrasion, and corrosive environments. Their construction ensures a long service life and consistent performance under rigorous use.

Manual Operation with Precision:The manual design allows for precise control during make-up and break-out processes, offering flexibility and reliability in both routine and challenging operations. The tongs are ideal for remote drilling sites or situations where powered tools are impractical.

Compliance and Certification:All Type DB Manual Tongs meet API 7K (American Petroleum Institute) and ISO (International Organization for Standardization) certifications, ensuring that they adhere to industry standards for safety, quality, and performance.

Safety and Ergonomics:The tongs are equipped with secure locking mechanisms, non-slip handles, and ergonomic grips to minimize operator fatigue and reduce the risk of accidents. The design helps maintain a firm grip and enhances operator safety during high-torque applications.

Specification:

| No.of Lug | Latch Jaws | No.of Hinge Pin Hole | Size Range | Rated Torque | ||

| In | mm | lb ·ft | KN ·m | |||

| 1# | I | 3 1/2-6 | 88.9-152 | 65000 | 90 | |

| II | 5 3/4-7 | 146-178 | ||||

| Ⅲ | 6 5/8-8 1/4 | 168-210 | ||||

| 2# | I | 8-9 5/8 | 203-244 | |||

| II | 10 5/8-11 1/4 | 270-286 | ||||

| 3# | I | 11 3/4-12 3/4 | 298-324 | 40000 | 55 | |

| II | 13 3/8-14 3/8 | 340-365 | ||||

| 4# | II | 16-17 | 406-432 | |||

| No.of Latch Lug Jaws | Latch Step | Size Range | Rated Torque | |

| In | mm | KN ·m | ||

| 1# | 1 | 3 1/2-4 1/8 | 88.9-104.78 | 55 |

| 2 | 4 1/8-5 | 104.78-127 | ||

| 2# | 1 | 4 1/4-5 1/4 | 107.95-133.35 | 75 |

| 2 | 5-5 3/4 | 127-146.05 | ||

| 3 | 6-6 3/4 | 152.4-171.45 | ||

| 3# | 1 | 6 5/8-7 1/4 | 168.28-184.15 | |

| 2 | 7 3/8-8 | 187.33-203.2 | ||

| 3 | 8 1/2-9 | 215.9-228.6 | 55 | |

| 4# | 1 | 9-9 5/8 | 228.6-244.48 | |

| 2 | 10 5/8-10 3/4 | 269.88-273.05 | ||

| 5# | 1 | 11 3/4 | 298.45 | 40 |

| 6# | 1 | 12 3/4-13 | 323.85-330.2 | |

| 7# | 1 | 1900/1 | 339.73 | |

Product Description:

The Type Q60-273/35 Well Servicing Tong is a critical tool designed for fastening and removing the screws of drill tools and casings during drilling and well-servicing operations. Built to accommodate a range of pipe sizes from 2-3/8 inches to 10-3/4 inches, these tongs are highly versatile and suitable for various tasks in both onshore and offshore environments.

Features:

One of the key features of the Type Q60-273/35 Well Servicing Tong is its adjustable handling size, which can be easily modified by changing the latch lug jaws and handling shoulders. This flexibility allows operators to quickly adapt to different pipe sizes, enhancing efficiency and reducing downtime during operations.

Constructed from high-quality, heat-treated alloy steel, the tong is built to withstand the high torque, stress, and harsh conditions typically encountered in drilling and well-servicing activities. Its robust design ensures durability and long service life, even under demanding use.

With its precise manual control and easy adjustability, the Type Q60-273/35 Well Servicing Tong is an essential tool for securing and maintaining well integrity, making it a valuable asset for any drilling or well-servicing operation.

Specification:

| No.of Latch Lug Jaws | Size Range | Rated Torque | ||

| In | mm | lb ·ft | kNm | |

| 1# | 2.3/8-4.1/2 | 60.3-114.3 | 25,000 | 35 |

| 2# | 4.1/2-6.1/2 | 114.3-165.1 | ||

| 3# | 6.1/2-8.5/8 | 165.1-219.1 | ||

| 4# | 9.5/8-10.3/4 | 244.5-273.1 | ||

Product Description:

The Type WWB Manual Tong, specifically the Q60-273/48 (2 3/8-10 3/4in), is a crucial tool in the oil drilling industry. It is designed to fasten or remove the screws of drill pipes, casing joints, or couplings, ensuring efficient and safe drilling operations.

Features:

Versatility: The WWB Manual Tong can handle a wide range of pipe sizes from 2 3/8 inches to 10 3/4 inches, making it suitable for various drilling applications.

Adjustability: By changing the latch lug jaws, the tool can be easily adjusted to fit different pipe sizes, enhancing its usability and efficiency.

Durability: Constructed from high-quality materials, the WWB Manual Tong is built to withstand the harsh conditions of drilling environments, ensuring long-term reliability.

Specification:

| No.of Latch Lug Jaws | Size Range | Rated Torque | ||

| in | mm | lb ·ft | KN·m | |

| 1# | 2 3/8-3 3/4 | 60.3-95.25 | 35000 | 48 |

| 2# | 3 1/2-4.5/8 | 88.9-117.48 | ||

| 3# | 4 1/2-5 3/4 | 114.3-146.05 | ||

| 4# | 5 1/4-7 1/4 | 133.35-184.15 | ||

| 5# | 6 7/8-8 5/8 | 174.63-219.08 | ||

| 6# | 9-10 3/4 | 228.6-273.05 | 25000 | 35 |

Applications:

Drill Pipe Handling: The primary use of the WWB Manual Tong is to fasten or remove screws on drill pipes, which is a critical task in drilling operations.

Casing Joint and Coupling: It is also used for handling casing joints and couplings, ensuring secure connections and disconnections during drilling.

Conclusion The Type WWB Manual Tong Q60-273/48 is an indispensable tool in the oil drilling industry. Its versatility, adjustability, and durability make it a reliable choice for handling drill pipes, casing joints, and couplings, contributing to the efficiency and safety of drilling operations.