Downhole Drilling Motor

Downhole Drilling Motor Principle

Downhole drilling motor is a kind of downhole dynamic drilling tool upon the power of drilling mud. Mud stream from the outlet of mud pump flows through a by-pass valve into the motor. This stream produces pressure loss at both inlet and outlet of the pump, to push the rotor into rotating, and to transmit the torque and speed onto the bit. The downhole drilling motor property mainly depends upon its property parameters.

Down-hole drilling motor is a positive-displacement motor. It converts high fluid power into mechanical energy of bit rotation. Down-hole motor is widely used for drilling, deflecting, azimuth control, coring, reaming, side tracking drilling and workover for horizontal well, cluster wells and straight well of oilfields and coal mines. In addition, it is suitable for complex drilling

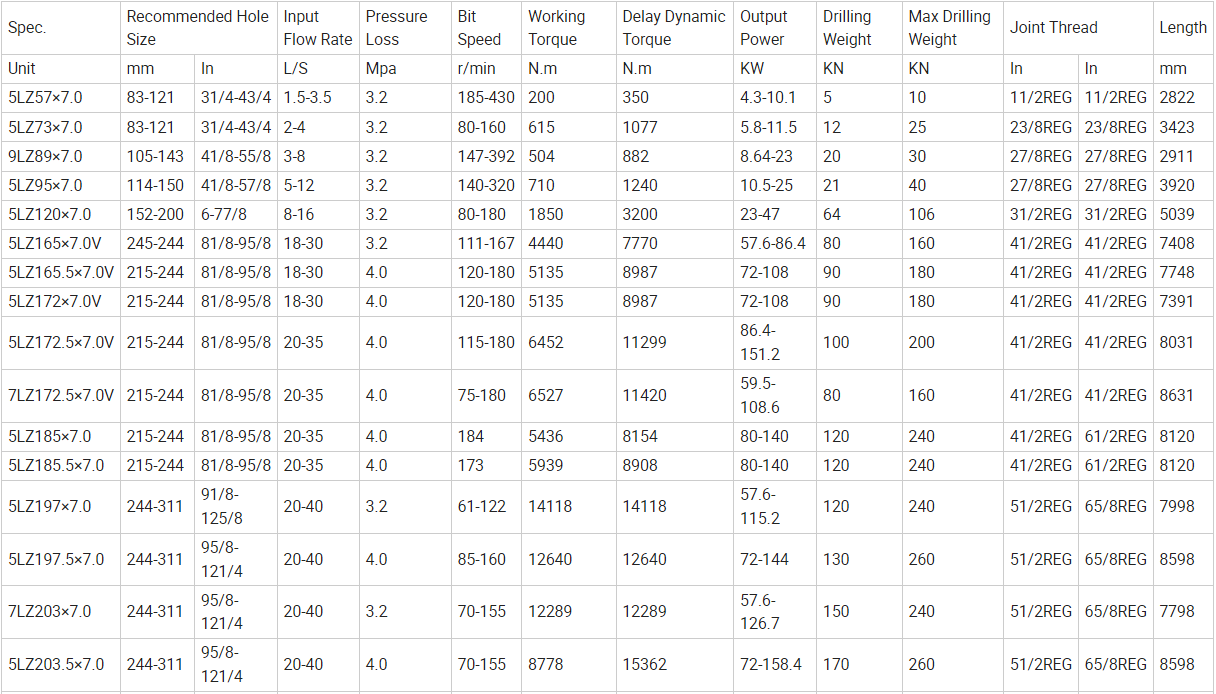

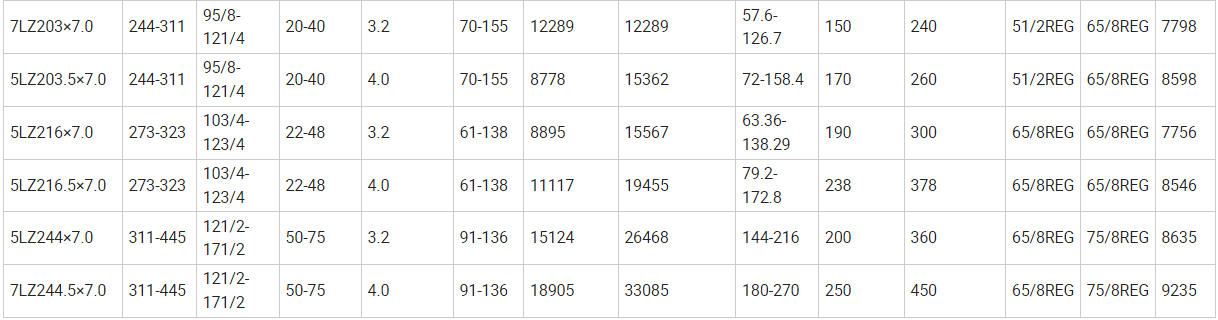

Specification of Downhole Motor

Downhole drilling motor is composed of five assemblies of bearing, power section, coupling, anti-drop and bypass valve.

Size of Downhole Drilling Motor

Various sizes of down-hole motors for hole sizes from 1 7/8" to 26".

Popular sizes are 1 11/16", 2 7/8", 3 1/8", 3 1/2", 3 3/4", 4", 4 3/4", 5", 5 5/16",5 7/8", 6 1/4", 6 1/2", 6 3/4", 7 1/4", 7 3/4", 8",8 1/4", 8 1/2", 9", 9 5/8" and 11 1/4".

we are able to provide down-hole motors of special size, high-speed, medium-speed and low-speed, according to customer's requirements