- Home

- >

- Products

- >

- Completion Packer

- >

Completion Packer

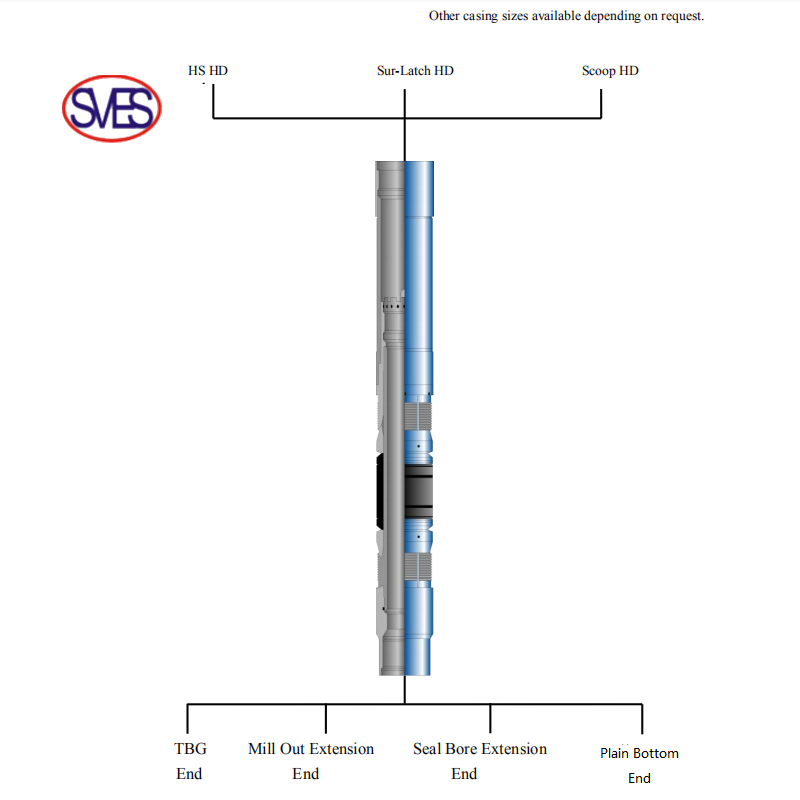

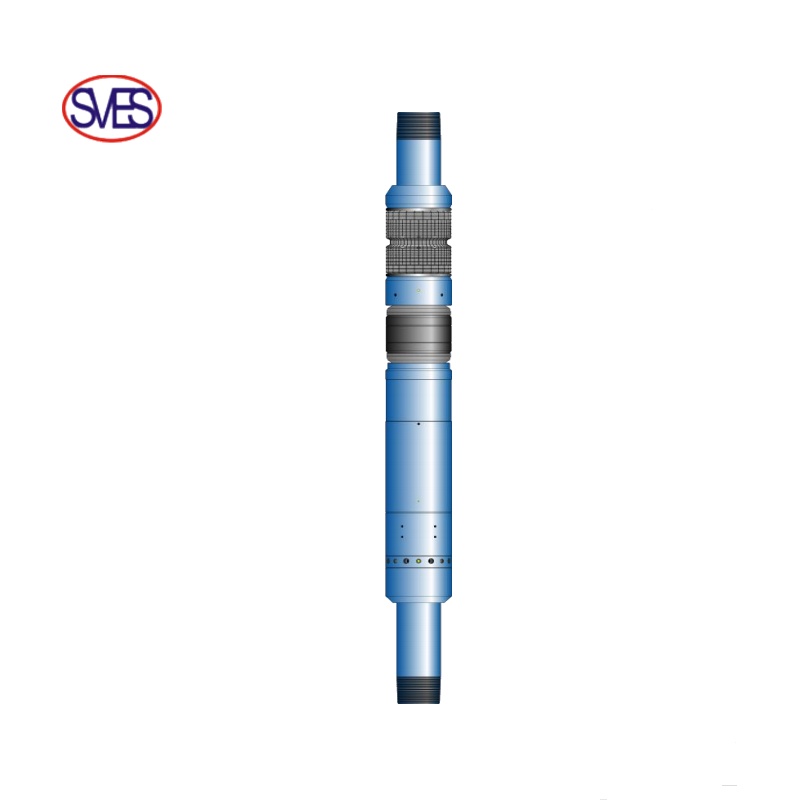

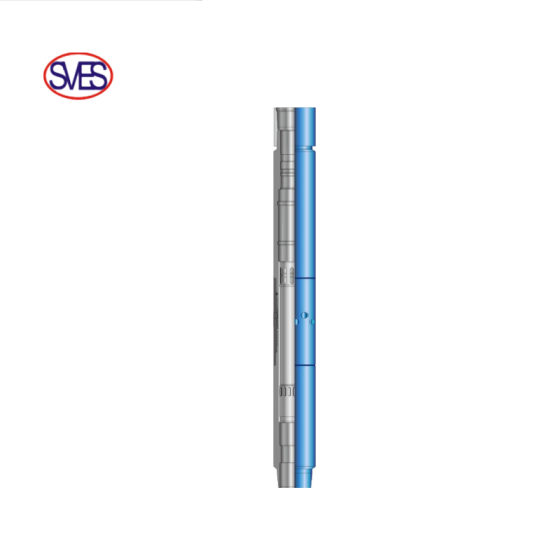

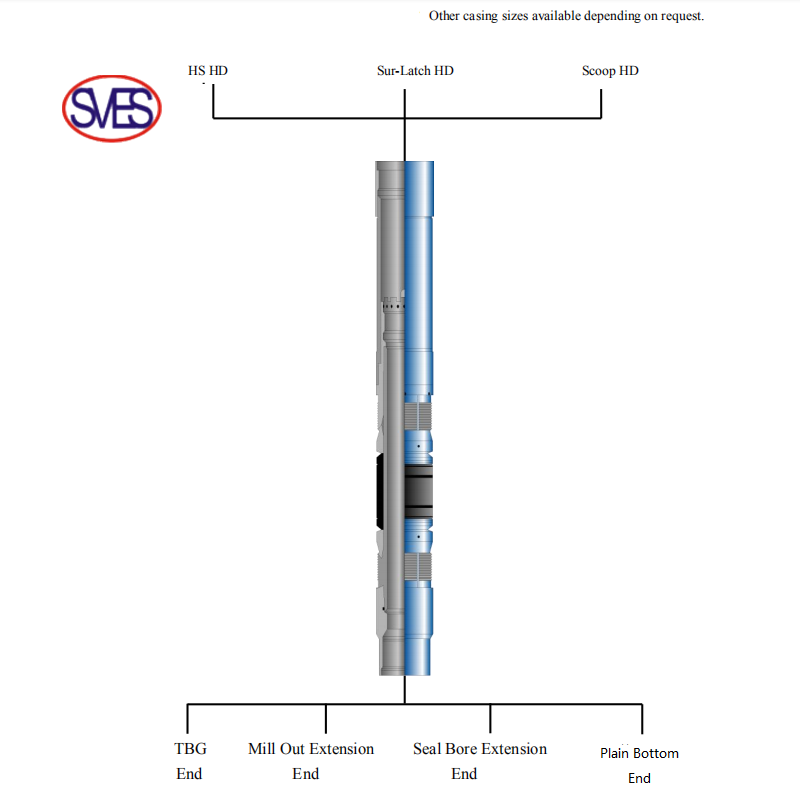

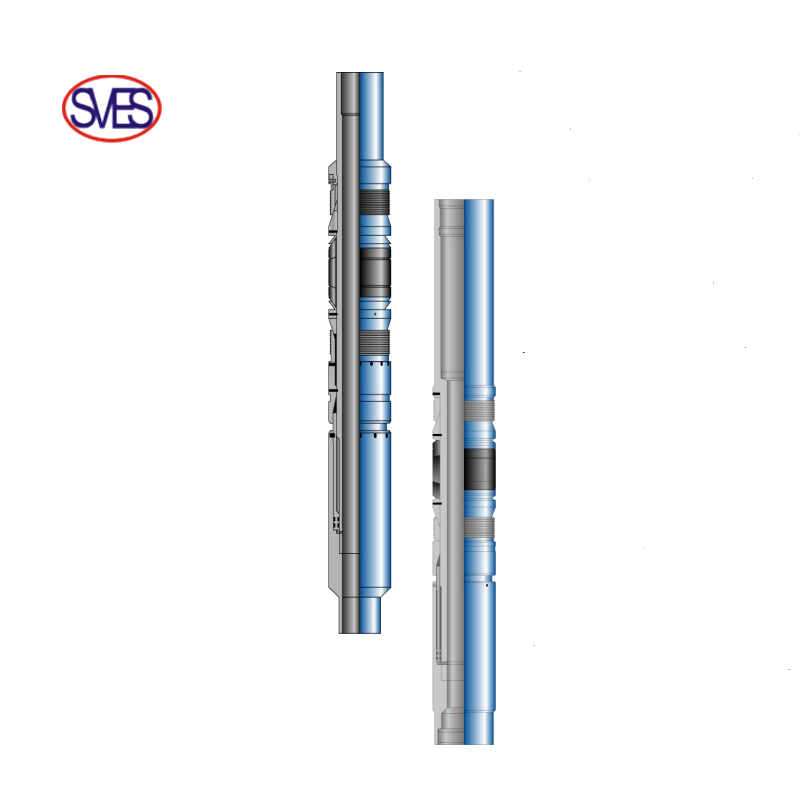

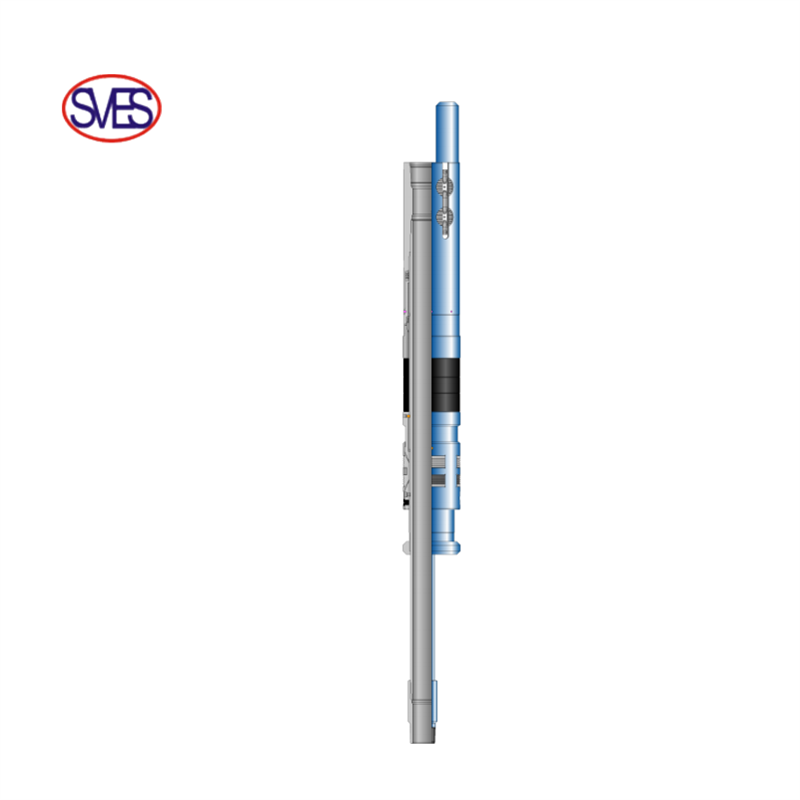

DWA Permanent Seal Bore Packers

DWA Wireline-Set Permanent Packer is designed to set in the well casing to divert casing-to-tubing flow. It is either hydraulically set with the hydraulic setting tool with tubing string pressure or the E-line setting tool. The DWA packer is mechanically moved and locked in the set position by the internal slip. An external set of opposing slips holds the packer against downward and upward forces. The removal of packer is by drill or milled out. The packer is designed with a left hand seal bore compatible with Sur Latch seal assemblies and the bottom sub thread is compatible with a mill-out extension or with a seal bore extension. The Packer is designed to be milled if removal from the wellbore required. Firstly remove the Sur-latch seal nipple from packer by tubing string, right-hand rotation with tension on the tubing to disengage the Sur-Latch from the packer head.

Features and Benefit

Full seal bore ID through the packer

Economical

Designed for most severe completion environments

Field proved reliable

Standard 10ksi rate

For high pressure and high temperature completions

Wireline and Hydraulic setting tools set

Milled if removal

Protected from pre-setting when run in hole

Designed for high tensile loads

Simple to operation

Provides an upper connector for attachment to seal unit locators

Tubing rotation available when run in hole

Applications

Production and injection sealbore packer

Horizontal completion assemblies

Sand control

Hanger packer in frac and stimulation jobs

Technical Data

Casing Size | Casing Weight | Packer OD | Sealbore ID | ||||

in. | mm | Ib/ft | kg/m | in. | mm | in. | mm |

4 1/2 | 114.30 | 9.5-12.6 | 14.14-18.75 | 3.79 | 96.27 | 2.55 | 64.90 |

9.5-13.5 | 14.14-20.09 | 3.72 | 94.49 | 2.37 | 60.33 | ||

13.5-15.1 | 20.09-22.47 | 3.64 | 92.46 | 2.55 | 64.90 | ||

13.5-16.8 | 20.09-25.00 | 3.60 | 91.44 | 2.37 | 60.33 | ||

5 | 127.00 | 15-21 | 22.32-31.25 | 3.96 | 100.58 | 2.55 | 64.90 |

23.2-24.2 | 34.53-36.01 | 3.79 | 96.27 | 2.55 | 64.90 | ||

5 1/2 | 139.70 | 13-20 | 19.35-29.76 | 4.54 | 115.32 | 2.75 | 69.85 |

13-20 | 19.35-29.76 | 4.54 | 115.32 | 3.00 | 76.20 | ||

20-26 | 29.76-38.69 | 4.36 | 110.74 | 2.75 | 69.85 | ||

20-26 | 29.76-38.69 | 4.36 | 110.74 | 3.00 | 76.20 | ||

23-28.4 | 34.23-42.26 | 4.26 | 108.20 | 3.00 | 76.20 | ||

6 5/8 | 168.28 | 17-32 | 25.30-47.62 | 5.47 | 138.89 | 2.75 | 69.85 |

17-32 | 25.30-47.62 | 5.47 | 138.89 | 3.25 | 82.55 | ||

20-24 | 29.76-35.72 | 5.69 | 144.45 | 4.00 | 101.60 | ||

7 | 177.80 | 17-20 | 25.30-29.76 | 6.25 | 158.75 | 4.00 | 101.60 |

17-23 | 25.30-34.23 | 6.18 | 156.97 | 3.25 | 82.55 | ||

20-26 | 29.76-38.69 | 6.00 | 152.40 | 4.00 | 101.60 | ||

23-38 | 34.23-56.55 | 5.69 | 144.45 | 2.75 | 69.85 | ||

23-38 | 34.23-56.55 | 5.69 | 144.45 | 3.25 | 82.55 | ||

23-32 | 34.23-47.62 | 5.88 | 149.23 | 4.00 | 101.60 | ||

32-38 | 47.62-56.55 | 5.69 | 144.45 | 4.00 | 101.60 | ||

32-45.4 | 47.62-56.56 | 5.69 | 144.45 | 2.75 | 69.85 | ||

32-45.4 | 47.62-56.56 | 5.69 | 144.45 | 3.25 | 82.55 | ||

7 5/8 | 193.68 | 26.4-39 | 39.29-58.04 | 6.38 | 161.93 | 2.75 | 69.85 |

26.4-39 | 39.29-58.04 | 6.38 | 161.93 | 3.25 | 82.55 | ||

26.4-39 | 39.29-58.04 | 6.38 | 161.93 | 4.00 | 101.60 | ||

33.7-39 | 50.15-58.04 | 6.38 | 161.93 | 4.50 | 114.30 | ||

33.7-45.3 | 50.15-67.41 | 6.18 | 156.97 | 3.25 | 82.55 | ||

8 5/8 | 219.08 | 36-49 | 53.57-72.92 | 7.26 | 184.40 | 4.00 | 101.60 |

9 5/8 | 244.48 | 36-47 | 53.57-69.94 | 8.42 | 213.87 | 6.00 | 152.40 |

36-59.4 | 53.57-88.40 | 8.12 | 206.25 | 3.25 | 82.55 | ||

36-59.4 | 53.57-88.40 | 8.12 | 206.25 | 4.00 | 101.60 | ||

| 36-59.4 | 53.57-88.40 | 8.12 | 206.25 | 5.00 | 127.00 | ||

| 40-53.5 | 59.53-79.62 | 8.22 | 208.79 | 6.00 | 152.40 | ||

47-58.4 | 69.94-86.90 | 8.16 | 223.11 | 6.00 | 152.40 | ||

The HHS Hydraulic Setting Tool is used to hydraulically set DWA permanent packers. To attach the hydraulic setting tool to the packer, the guide tube on the packer is replaced with a modified hydraulic tube guide that is listed in the packer's Engineering Design Specifications. With the setting sleeve on the packer replaced with the hydraulic tube guide, the setting tool is attached to the packer by lugs and shear pins. The setting tool is made up on the bottom of the work string and run into the well with the packer. After the packer is set, the setting tool is released from the packer by a straight upward pull.

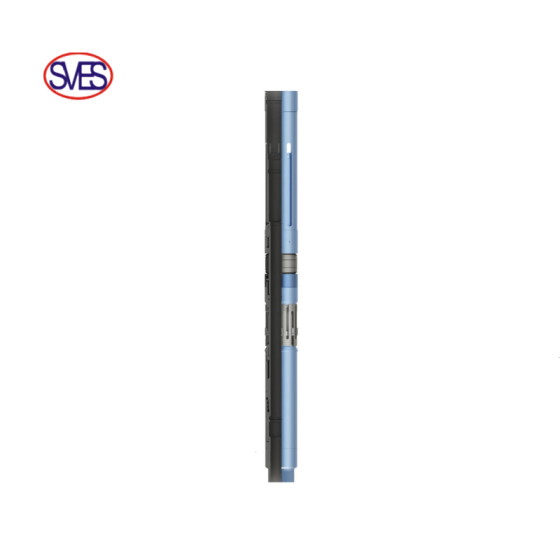

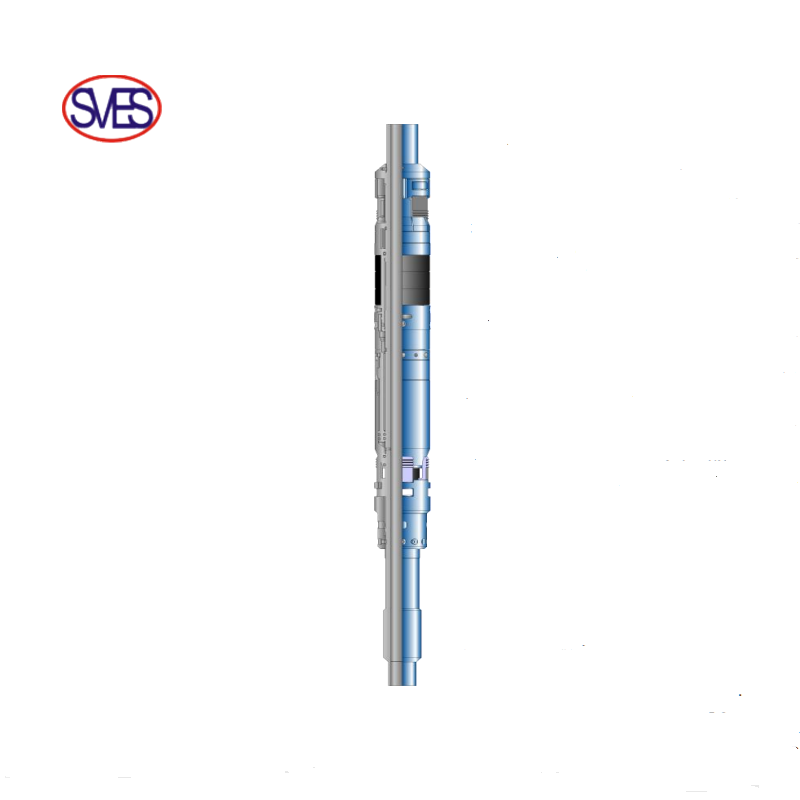

HRM Hydraulic Set Permanent Packer

HRM Packer is designed for use in applications where one trip to completion and frac is required. The packer is a hydraulic set single trip permanent millable packer with smaller OD feature is used for restrict ID casing or smaller size frac string. The packer can with Top Tubing Thread or Latch Thread. Bottom sub threaded for mill-out extension or the customer's liner. The packer design around a proven base of sealing integrity, slip anchoring system and utilizes an integral one-piece mandrel with only three pressure sealing threads within the assembly. The packer is designed with premium seal for severe down hole environments such as sour and HPHT. The Packer is designed to be milled if removal from the wellbore required. Firstly remove the Sur-latch seal nipple from packer by tubing string, right-hand rotation with tension on the tubing to disengage the Sur-Latch from the packer head.

Features and Benefit

• Field proved reliable

• Simple to operation

• Designed for most severe completion environments

• For high pressure and high temperature completions

• Large ID

• Designed for high tensile loads

• Metal to metal premium thread connection, or seal anchor assembly

• Single piece mandrel and seal bore

• Minimized potential leak paths

• Up to 15ksi rate

Applications

• Act as a tubing hanger

• High deviated and horizontal completion wells

• Single trip production and injection wells

• High pressure and high temperature wells

• Frac and stimulation

• Extreme completion environments such as sour gas

Technical Data

Casing Size | Casing Weight | Packer OD | Packer ID | Sealbore ID | |||||

in. | mm | lb/ft | kg/m | in. | mm | in. | mm | in. | mm |

5 | 127.00 | 15-21 | 22.32-31.25 | 3.96 | 100.58 | 1.91 | 48.51 | 3.12 | 79.25 |

5 1/2 | 139.70 | 14-20 | 20.83-29.76 | 4.54 | 115.32 | 2.36 | 59.94 | 3.50 | 88.90 |

23-26 | 34.22-38.69 | 4.36 | 110.74 | 2.36 | 59.94 | 3.50 | 88.90 | ||

6 5/8 | 168.28 | 17-32 | 25.30-47.62 | 5.47 | 138.89 | 3.17 | 80.52 | 4.25 | 107.95 |

17-20 | 25.30-29.76 | 5.88 | 149.23 | 3.88 | 98.43 | 5.00 | 127.00 | ||

7 | 177.80 | 17-23 | 25.30-34.22 | 6.8 | 156.97 | 3.17 | 80.52 | 4.25 | 107.95 |

17-20 | 25.30-29.76 | 6.25 | 158.75 | 3.88 | 98.43 | 5.00 | 127.00 | ||

20-32 | 29.76-47.62 | 5.88 | 149.25 | 3.88 | 98.55 | 5.00 | 127.00 | ||

32-38 | 47.62-52.09 | 5.55 | 140.97 | 3.02 | 76.71 | 4.25 | 107.95 | ||

32-44 | 47.62-65.48 | 5.47 | 138.89 | 3.02 | 76.71 | 4.25 | 107.95 | ||

7 5/8 | 193.68 | 26.4-39 | 39.29-59.04 | 6.38 | 161.95 | 3.88 | 98.55 | 5.00 | 127.00 |

33.7-45.3 | 50.15-67.41 | 6.17 | 156.72 | 3.88 | 98.55 | 5.00 | 127.00 | ||

33.7-47.3 | 50.15-70.39 | 6.18 | 156.97 | 3.17 | 80.52 | 4.25 | 107.95 | ||

9 5/8 | 244.48 | 36-59.4 | 53.57-88.40 | 8.13 | 206.40 | 4.85 | 123.19 | 6.50 | 165.10 |

40-47 | 59.53-69.94 | 8.42 | 213.87 | 6.00 | 152.40 | 7.00 | 177.80 | ||

53.50 | 79.62 | 8.31 | 211.07 | 6.02 | 152.98 | 7.25 | 184.15 | ||

10 3/4 | 273.05 | 55.5-60.7 | 82.59-90.33 | 9.28 | 235.71 | 6.00 | 152.40 | 7.00 | 177.80 |

60.7-65.7 | 90.33-97.77 | 9.28 | 235.71 | 6.00 | 152.40 | 7.00 | 177.80 | ||

* Other casing sizes available depending on request.* Other ID available depending on tubing size selected.

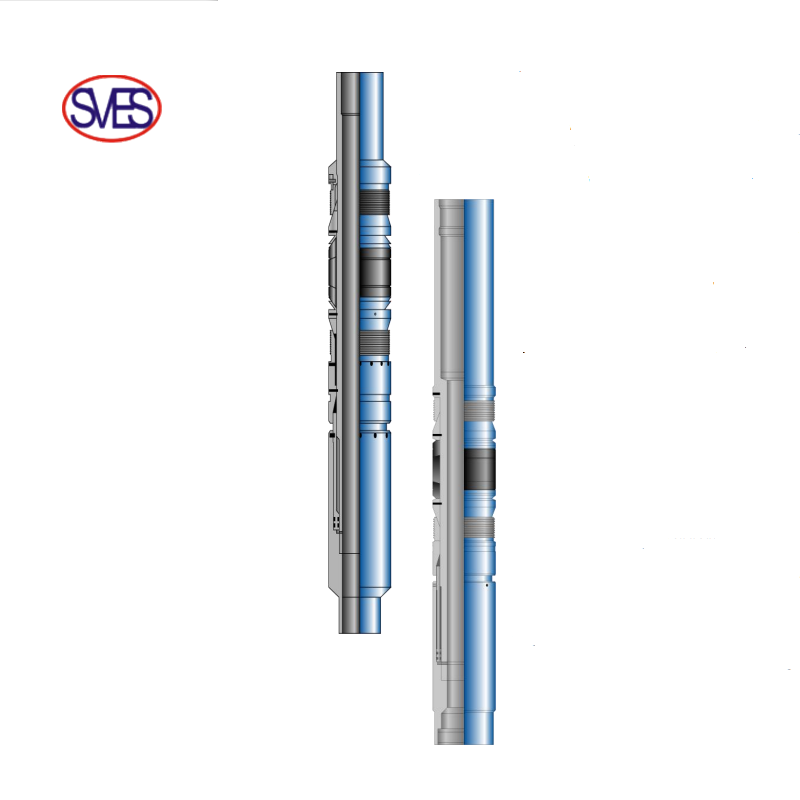

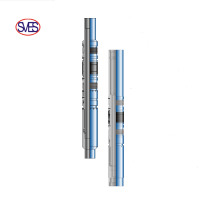

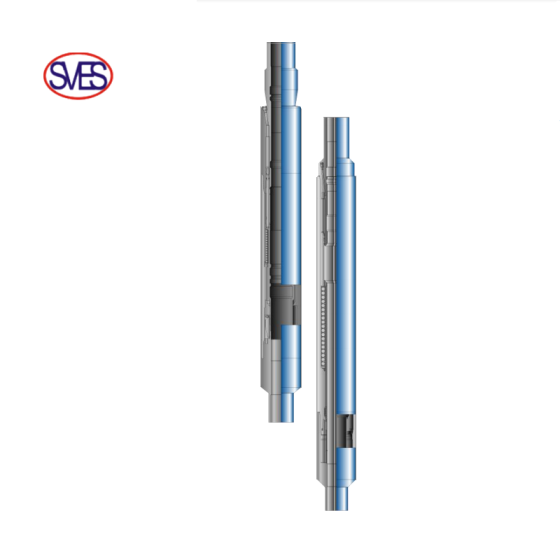

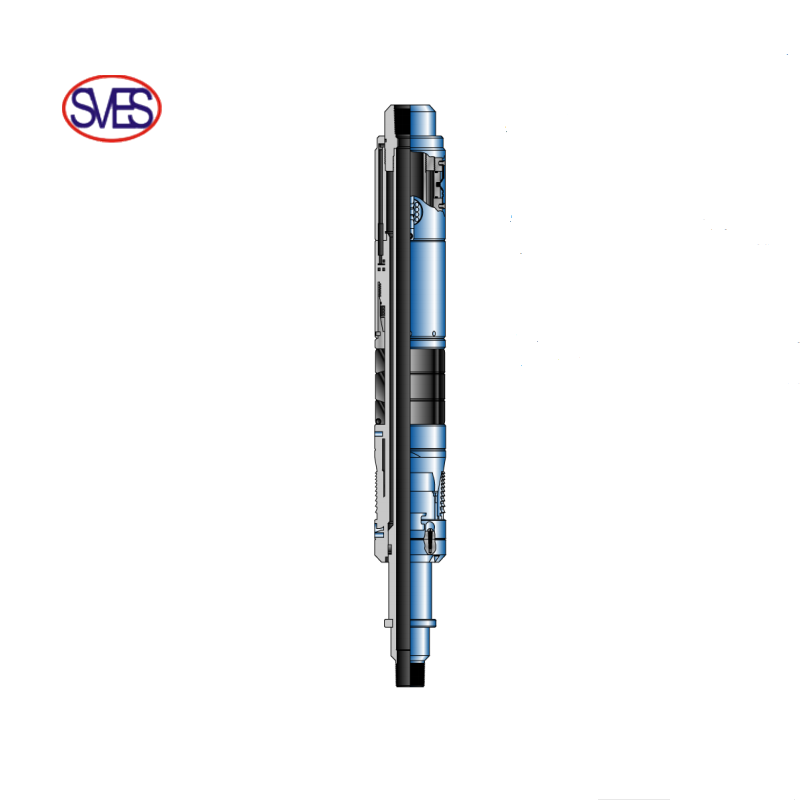

ABV Retrievable Seal Bore Packers

ABV Packer is a retrievable, single-bore packer that has the completion features of a large-bore packer. The packer delivers high performance with simplicity of design and desirable economics. It is a 10,000 PSI plus rated packer and can be equipped to withstand severe corrosion and high temperatures.

The packers are designed to be used in Frac or gravel pack service, or suspend tools, or provide a pressure isolation point in the casing, which can be set by using hydraulic setting tool, and be pulled by running and latching the retrieving tool then applying a straight upward pull if needed.

Features and Benefit

• Field proved reliable

• Simple to operation

• Economical

• Designed for most severe completion environments

• For high pressure and high temperature completions

• Provides an upper connector for attachment to seal unit locators

• Full seal bore ID through the packer

• Designed for high tensile loads

• Wireline and Hydraulic setting tools set

• Protected from pre-setting when run in hole

• Tubing rotation available when run in hole

• Retrievable

• Able to be milled if retrieval attempts fail

• Standard 10ksi rate

Applications

• Sand control

• Horizontal completion assemblies

• Hanger packer in frac and stimulation jobs

• Production and Injection sealbore packer

• Retrieve required

Technical Data

Casing Size | Casing Weight | Packer OD | Packer Bore | ||||

in. | mm | Ib/ft | kg/m | in. | mm | in. | mm |

4 1/2 | 114.30 | 9.5-11.6 | 14.14-17.26 | 3.82 | 97.03 | 2.38 | 60.45 |

5 | 127.00 | 15-18 | 22.32-26.79 | 4.09 | 103.89 | 2.55 | 64.77 |

5 1/2 | 139.70 | 17-20 | 25.30-29.76 | 4.61 | 117.09 | 2.75 | 69.85 |

23-26 | 34.22-38.69 | 4.36 | 110.74 | ||||

6 5/8 | 168.28 | 28 | 41.66 | 5.53 | 140.46 | 3.25 | 82.55 |

20-24 | 29.76-35.71 | '5.73 | 145.54 | ||||

7 | 177.80 | 49.5-50.1 | 73.66-74.56 | 5.30 | 134.62 | 3.00 | 76.20 |

41-44 | 61.01-65.47 | 5.53 | 140.46 | 3.25 | 82.55 | ||

32-38 | 47.62-56.54 | 5.73 | 145.54 | ||||

23-29 | 34.22-43.15 | 6.00 | 152.40 | ||||

17-23 | 25.30-34.22 | 6.19 | 157.23 | ||||

32-35 | 47.62-52.09 | 5.82 | 147.83 | 3.88 | 98.55 | ||

23-29 | 34.22-43.15 | 6.00 | 152.40 | ||||

17-23 | 25.30-34.22 | 6.19 | 157.23 | ||||

7 5/8 | 193.7 | 42.4-47.1 | 35.72-70.79 | 6.19 | 157.23 | 3.25 3.88 | 82.55 98.55 |

29.7-39 | 44.19-58.03 | 6.44 | 163.58 | ||||

24-29.7 | 35.71-44.19 | 6.68 | 169.67 | ||||

7 3/4 | 196.85 | 46.1-48.6 | 68.6-72.32 | 6.19 | 157.23 | 3.25 | 82.55 |

3.88 | 98.55 | ||||||

8 5/8 | 219.08 | 28-36 | 41.67-53.57 | 7.63 | 193.80 | 3.88 | 98.55 |

9 5/8 | 244.48 | 43.5-53.5 | 64.73-79.62 | 8.30 | 210.83 | 3.88 | 98.55 |

36-43.5 | 53.57-64.73 | 8.52 | 216.41 | 5.00 | 127.00 | ||

43.5-47 | 64.74-69.94 | 8.45 | 214.63 | 6.00 | 152.40 | ||

10 3/4 | 273.05 | 51-65.7 | 75090-97.77 | 9.31 | 236.47 | 5.00 | 127.00 |

13 3/8 | 339.73 | 68-72 | 101.18-107.14 | 12.13 | 308.10 | 6.00 | 152.40 |

HST hydraulic setting tool is used to set ABV or DWA packer. The HST tool is attached to the top sub of the packer by pins or by the left hand thread by rotational. The set of lugs latches into the setting sleeve of the packer.

When without a lower plugging device in the tailpipe the large internal by-pass allows fluid to enter the work string eliminating the need to fill the work string while running in the hole. If there is tailpipe assembly such as the Multi-Stage Frac system with some type of float shoe or other type of plugging device is in place then it may be necessary to fill while running in the hole.

Once the packer has reached the desired depth, the tripping ball is dropped to land in ball seat circulation valve. Field adjustable differential pressure is applied activating a hydraulic chamber stroking the setting Tool against the packer which engages the slips and energizes the elements. There is a secondary ball seat within the setting tool if required.

Once the packer is set, annual pressure test can be performed. The HST setting tool is released with a combination of right hand rotation while holding tension, or continue pressure the running string to hydraulic to release.

Features and Benefits

• Left hand thread connection allows heavy tail pipe weight

• Right hand rotate release and hydraulic release are available

• Anti-preset design

•Two stage ball seat permits reset the packer

Technical Data

Casing Size | Packer Bore | Max | O.D. | Min | LD. | STD Connection | |||

in | mm | in | mm | mm | mm | in | mm | ||

7 | 177.8 | 3.88 | 98.55 | 5.70 | 144.78 | 2.25 | 57.15 | 3 1/2 IF | 88.9 |

7 | 177.8 | 4.00 | 101.6 | 5.70 | 144.78 | 3.00 | 76.20 | 3 1/2 IF | 88.9 |

9 5/8 | 244.5 | 6.00 | 152.40 | 8.02 | 203.71 | 2.25 | 57.15 | 4 1/2 IF | 114.3 |

The retrieving tools are is a latch type retrieving tool used to retrieve ABV packers. To retrieve the packer, the retrieving tool is run on a work string, stung into the packer bore, and latched into the packer. Once latched, downward set down engage the packer's release sleeve and upward moves to release. Additional upward movement of the work string sheared releases the sleeve and moves the packer mandrel upward, which permits the packer slips to retract and pick up the packer to be retrieved.

For emergency release, continue straight pull will shear the shear screws in the spring housing and allow shear ring to move by spring to push the spring housing downward and collapse the dogs inward, this allow the retrieving tool free to rotate out and pull back from the hole.

Features and Benefits

• No rotation is required for pulling operation

• Straight-through ID allows washing down to the packer

• Easy to release: 1/4 turn on lug-type tools, and six to eight turns on an acme tool

• Rugged lug-type design engages the release sleeve

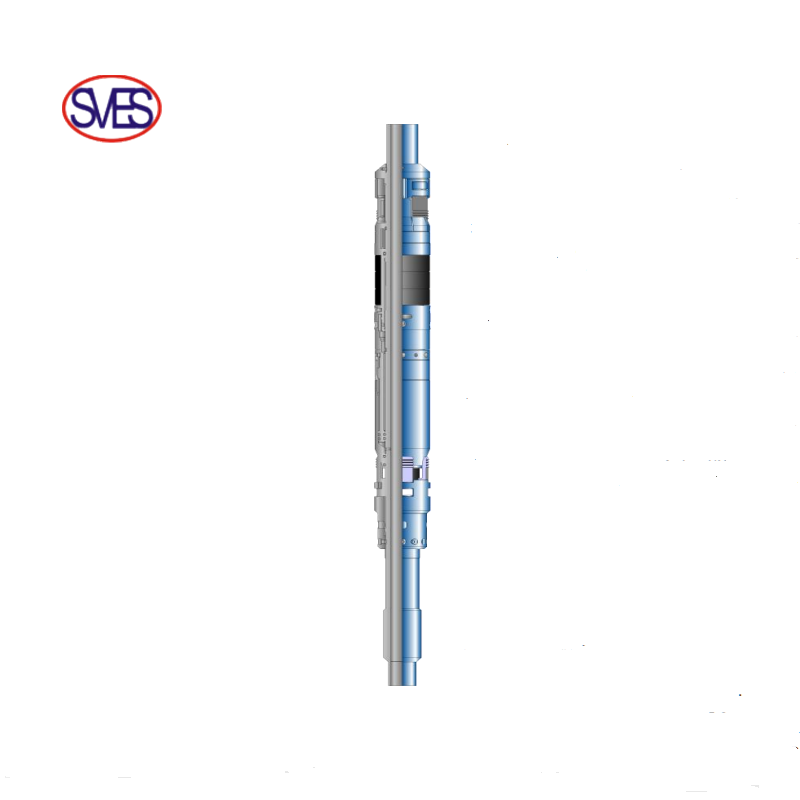

HPL Hydraulic-Set Retrievable Packer

HPL Hydraulic-Set Retrievable Packer is a single-string, hydraulic-set retrievable packer designed for Single or multi-packer production completions. The packer is made up to the tubing string and run into the well. At the desired setting depth, pressure is applied down the tubing string against a plugging device below the packer. When the full setting pressure is applied, the packer slips and elements should be fully engaged and held in the set position by internal spring loaded slips. The Packer design allows for no mandrel movement during the setting sequence.

The Packers can be run either in single packer or multiple packer completions. When used in multiple packer completions, the setting pressure can be adjusted to allow the packers to be set and tested individually.

To release the Packer, straight pull on the tubing is all that is required. Straight pull on the tubing shears a set of release pins which allows the packer mandrel to move upward moving the supports from beneath the slips. Further upward movement relaxes the elements and enables the packer to be retrieved.

Features & Benefits

• Field proved reliable

• High performance at low cost

• Small OD

• Hydraulically-set for safe, dependable operation in multiple packer applications

• Triple-seal multidurometer elements

• Shear screws allow operator to vary the setting pressure and release force

• No mandrel movement when setting

• Requires only a straight pull to release

• Multiple packers can be run and set in one trip

• Standard 7.5ksi rate

Applications

• Single or multi-packer production completions

• Production and injection wells.

• The lower packer in dual completions

• Act as a bridge plug with an on off tool.

• Multi-zone completions

Technical Data

Casing Size | Casing Weight | Max OD | Min ID | ||||

in | mm | lb/ft | Kg/m | in | mm | in | mm |

5 1/2 | 139.70 | 13-17 | 19.35-25.30 | 4.690 | 119.13 | 2.36 | 58.41 |

17-23 | 25.30-34.22 | 4.52 | 114.68 | 2.36 | 58.41 | ||

7 | 177.80 | 23-29 | 34.22-43.16 | 5.99 | 152.15 | 2.89 | 73.41 |

29-35 | 43.16-52.09 | 5.83 | 148.08 | 2.89 | 73.41 | ||

7 5/8 | 193.68 | 29.7-39 | 44.20-58.04 | 6.46 | 164.08 | 2.89 | 73.41 |

9 5/8 | 244.48 | 40-47 | 59.53-69.94 | 8.45 | 212.85 | 3.89 | 98.81 |

47-53.5 | 69.94-79.62 | 8.23 | 209.12 | 3.89 | 98.81 | ||

* Other casing sizes available depending on request.* Other ID available depending on tubing size selected.

SRH Hydraulic-Set Retrievable Packer

The SRH Hydraulic-Set Retrievable packer is a retrievable single-string packer which is designed to be set by plugging the tubing below the packer and applying internal pressure. The packer is retrieved by simply raising the tubing string to shear the release shear pins.

The packer does not require mandrel movement to establish a full set which makes it suitable for multi-packer installations. The packer is capable of hanging heavy tailpipe loads in the casing and is available with selective-set mechanisms.

The packer is suitable for production and injection installations. In addition, service applications such as stimulation and tubing-conveyed perforating operations may also be carried out using this packer taking special precautions to prevent premature shear of the release pins.

Features and Benefit

• Field proved reliable

• Designed for deep or deviated wells

• Production and Injection application

• Designed for high tensile loads

• Internal locking mechanism

• Protected from pre-setting when RIH

• hydraulic-actuated hold down slips above

• Standard slips below the elements to bite into the casing

• Lower setting pressure

• Prevents both upward and downward movement

• Straight pull to release

• Field adjustable the setting pressure and shear release

• Standard 7.5ksi rate

Applications

• Single or multi-packer production completions

• Production and injection wells

Frac and stimulation jobs

Technical Data

Casing Size | Casing Weight | Max OD | Min ID | ||||

in | mm | lb/ft | Kg/m | in | mm | in | mm |

5 1/2 | 139.70 | 13-17 | 19.35-25.30 | 4.62 | 117.35 | 1.93 | 49.02 |

17-23 | 25.30-34.22 | 4.51 | 114.55 | 1.93 | 49.02 | ||

7 | 177.80 | 17-23 | 25.30-34.22 | 6.19 | 157.23 | 2.90 | 73.66 |

23-29 | 34.22-43.16 | 6.01 | 152.65 | 2.90 | 73.66 | ||

29-35 | 43.16-52.09 | 5.83 | 148.08 | 2.90 | 73.66 | ||

7 5/8 | 193.68 | 24-29.7 | 35.72-44.20 | 6.63 | 168.40 | 2.90 | 73.66 |

33.7-39 | 50.15-59.04 | 6.39 | 162.31 | 2.90 | 73.66 | ||

9 5/8 | 244.48 | 36-40 | 53.57-59.53 | 8.63 | 219.20 | 2.90 | 73.66 |

40-47 | 59.53-69.94 | 8.37 | 212.85 | 4.80 | 121.92 | ||

47-53.5 | 69.94-79.62 | 8.32 | 211.33 | 4.80 | 121.92 | ||

* Other casing sizes available depending on request.* Other ID available depending on tubing size selected.

RHA Hydraulic-Set Retrievable Packer

The RHA packer is a hydraulic-set retrievable single-string packer which is design for high pressure, large ID or TCP applications. The packer allows multiple bores or control line feed -through.

Except straight-shear release features, the RHA packer can be set up cut to release which is use to high pressure or heavy tailpipe. The cage slip, which distributes the packer to casing loads more.

Features and Benefits

• Field proved reliable

• Production and Injection application

• Large ID

• Single piece mandrel

• No mandrel movement for multi zone stacked packer application

• Single trip capability

• Multiple bores or control line feed-through

• Straight pull to release or cut to release

• Used in high pressure, large ID or TCP well condition

• Field adjustable the setting pressure and shear release

• Upper tubing connection or Latch head

Applications

• Single or multi-packer production completions

• Production and injection wells

• TCP

• Production and injection wells

Technical Data

Casing Size | Casing Weight | Packer OD | Packer ID | ||||

in. | mm | lb/ft | kg/m | in. | mm | in. | mm |

5 1/2 | 139.70 | 13-17 | 19.34-25.30 | 4.71 | 119.63 | 2.89 | 73.41 |

20-23 | 29.76-34.22 | 4.47 | 113.54 | 2.89 | 73.41 | ||

7 | 177.80 | 26-29 | 38.69-43.16 | 5.95 | 151.13 | 3.92 | 99.57 |

32-35 | 47.62-52.09 | 5.83 | 148.08 | 3.92 | 99.57 | ||

7 5/8 | 193.68 | 29.7-39 | 44.20-58.03 | 6.43 | 163.32 | 3.92 | 99.57 |

9 5/8 | 244.48 | 40-47 | 59.53-69.94 | 8.48 | 215.39 | 4.88 | 123.95 |

43.5-53 | 64.74-78.86 | 8.29 | 210.57 | 4.88 | 123.95 | ||

* Other casing sizes available depending on request.* Other ID available depending on tubing size selected.

LSP Mechanical -Set Retrievable Packer

The LSP Mechanical-Set Retrievable packer is design for testing zone stimulation application. The packer run, set, released and reset in one trip. Internal J-Latch holds the packer set, and only 1/4 turn of tubing at packer to set and release. Second straight pull shear release available when the tubing rotating limited. The feature of fluid bypass areas through the packer allows high run in hole speed. The LSP packer can be use as tubing anchor or temporary bridge plug. Pressure can be up to 10K.

Features and Benefits

• Field proved reliable

• Testing and stimulation application

• Tubing anchor or temporary bridge plug application

• Internal J-Latch holds the packer set

• 1/4 turn of tubing at packer to set and release

• Reset and release packer in one trip

• Easy redress and reassemble

• High run speed when run in hole

• Shear release for option

• High pressure rating, Standard 10ksi

Applications

• Well testing

• Frac and stimulation

• Temporary bridge plug

• Tubing hanger

Technical Data

Casing Size | Casing Weight | Packer OD | Packer ID | ||||

in. | mm | lb/ft | Kg/m | in. | mm | in. | mm |

5 1/2 | 139.70 | 13-17 | 19.35-25.30 | 4.69 | 119.12 | 2.40 | 60.96 |

20-23 | 29.76-34.23 | 4.51 | 114.55 | 2.40 | 60.96 | ||

7 | 177.80 | 20-26 | 29.76-38.69 | 6.03 | 153.16 | 2.98 | 75.69 |

26-32 | 38.69-47.62 | 5.91 | 150.11 | 2.98 | 75.69 | ||

32-38 | 47.62-56.55 | 5.70 | 144.78 | 2.98 | 75.69 | ||

41-44 | 61.01-65.48 | 5.50 | 139.70 | 2.98 | 75.69 | ||

7 5/8 | 193.68 | 26.4-29.7 | 39.29-44.20 | 6.65 | 168.91 | 2.98 | 75.69 |

29.7-39 | 44.20-58.04 | 6.45 | 163.83 | 2.98 | 75.69 | ||

9 5/8 | 244.48 | 36-43.5 | 53.57-64.74 | 8.55 | 217.17 | 3.88 | 98.55 |

* Other casing sizes available depending on request.* Other ID available depending on tubing size selected.

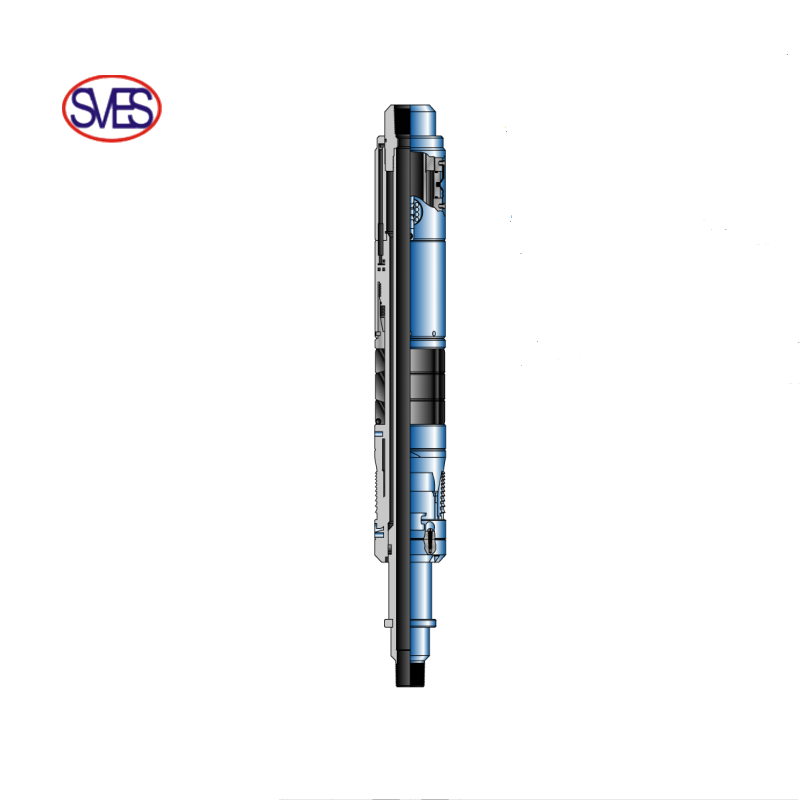

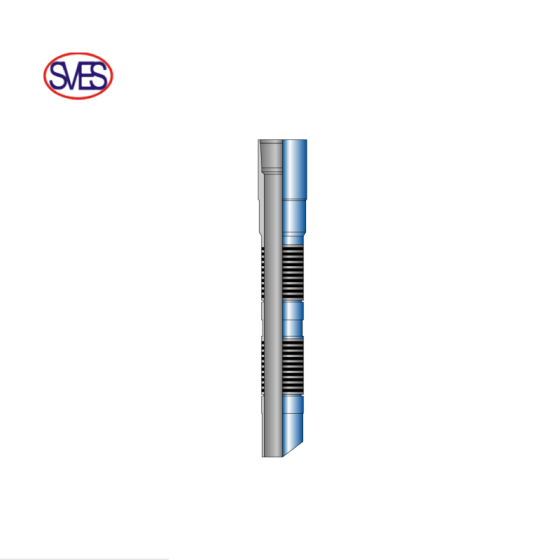

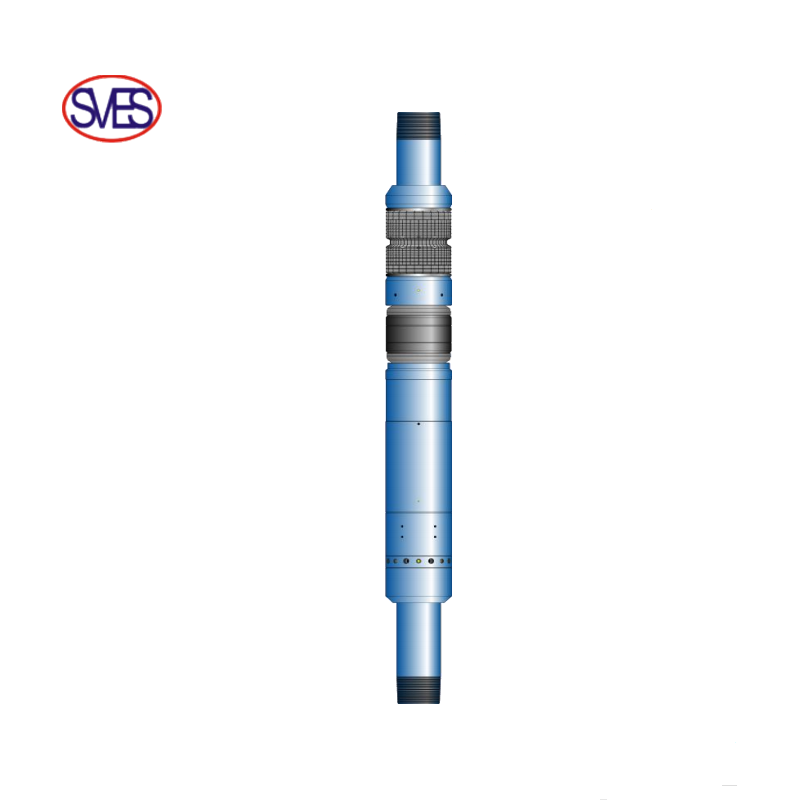

ESP Hydraulic-Set Retrievable Packers

ESP packer is designed to be run with Electric Submersible Pumps. The packer is a hydraulic-set, straight pull shear release, upper single-string, double-bore retrievable packer.

The packer with several additional optional ports allows venting of annular pressure, fluid injection through the packer, and/or instrument wire port bypass. The vent valve is designed to be threaded to the top of the packer. The valve is hydraulically operated and allows for gas bypass around the packer. The packer comes with a plug for when the vent valve is not used.

Features

• Hydro-test capability of feed through connection.

• A pack-off power cable feed-through system is provided with thread connections

• Additional bores for venting of annular pressure, chemical-injection lines, control lines, and well-monitoring devices through the packer

• Slip design offers exceptional hang weight capability

• Case carburized bi-directional slips anchor the packer against well pressure from above or below

Benefits

• Field redress is quick, easy, and cost effective

• Efficiently reduce the overall costs of submersible pump completions

• Performance is long-term and dependable

• No relative movement between tubing and cable

• Low pressure set

• Requires only straight pull to release

• Field adjusted the setting pressure and shear value

• Allows adjustment of pull-to-release in the field

Casing | Max.OD | Pressure Rating | Pressure Rating | |||||

Size | Weight | |||||||

in. | mm | lb | in. | mm | in. | mm | psi | MPa |

7 | 177.8 | 23-26 | 6.10 | 154.94 | 2.360 | 59.94 | 3000-5000 | 20.7-35 |

26-29 | 5.99 | 152.15 | ||||||

29-32 | 5.94 | 150.88 | ||||||

9 5/8 | 244.5 | 36-40 | 8.59 | 218.19 | 2.918 | 74.12 | 3000-5000 | 20.7-35 |

40-47 | 8.50 | 215.90 | ||||||

47-53.5 | 8.26 | 209.80 |