- Home

- >

- Products

- >

- Safety Valve

- >

Safety Valve

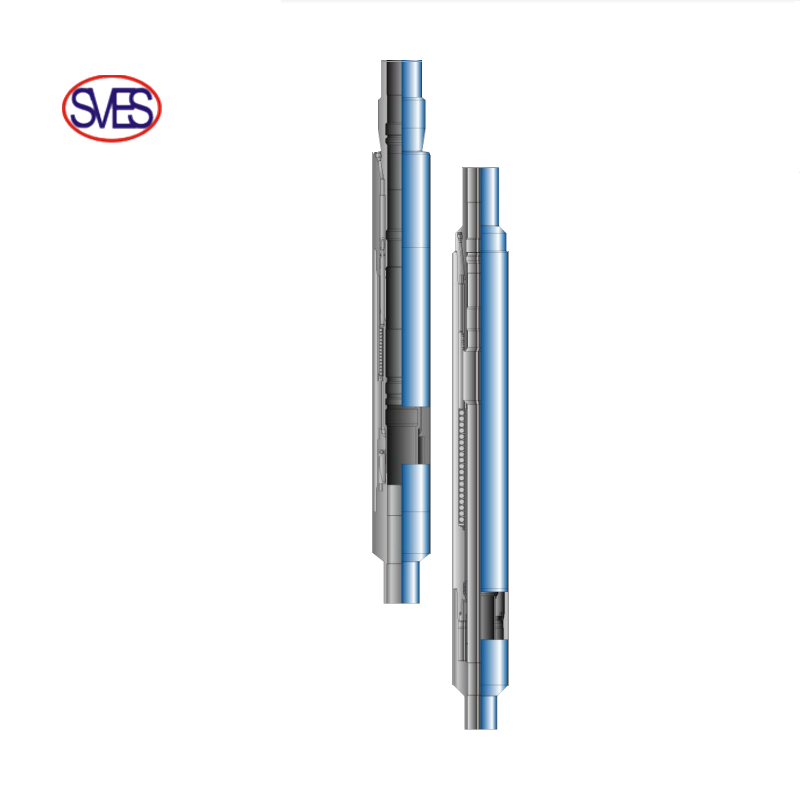

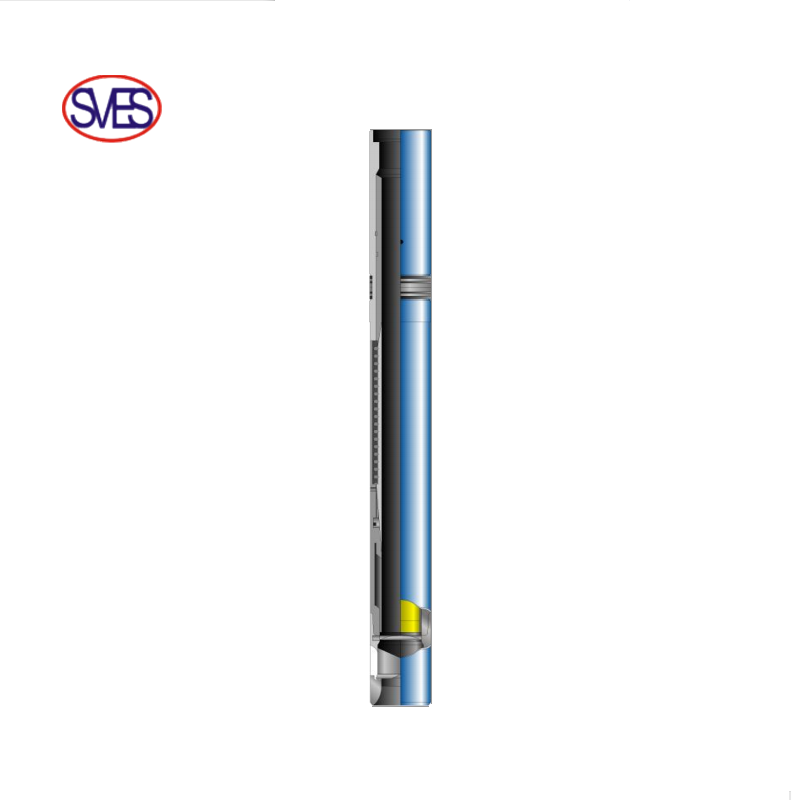

Tubing -Retrievable Safety Valves

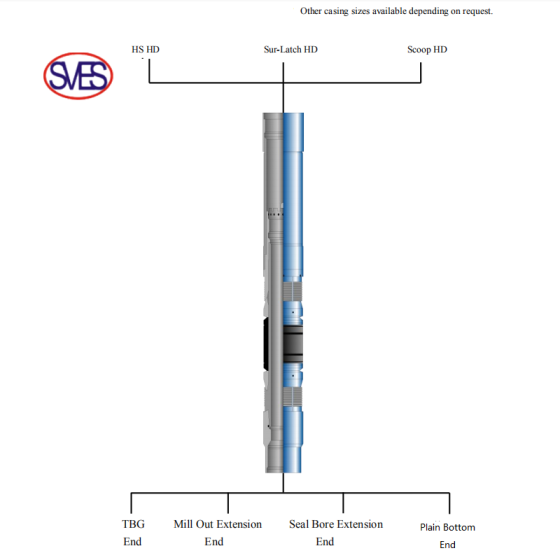

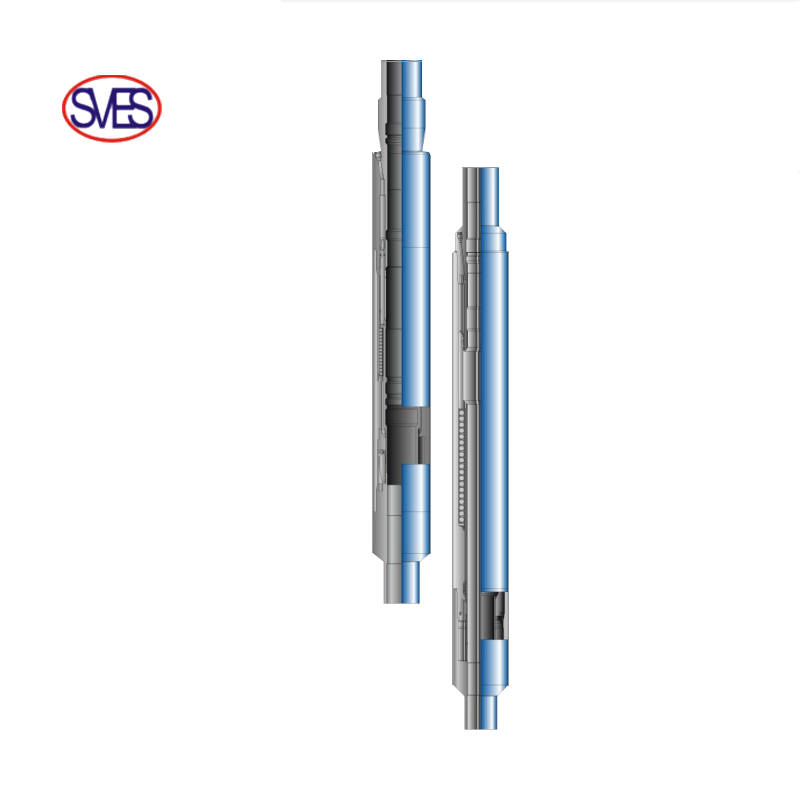

Tubing Retrievable Safety Valves are self-equalizing, flapper type safety valve designed to shut in a well at a point below the surface. The safety valve is a surface controlled, subsurface safety valve and is normally closed. The valve is held open by hydraulic control pressure and remains open until the control-line pressure is exhausted. The hydraulic control pressure is transmitted from a remote location through a control line to operate the valve. The valves are value engineered to provide long-lasting, safe, and reliable operation.

Rod Piston Safety Valves are designed and built for performance and reliability. The rugged hydraulic actuator of the safety valve provides durability and isolates the internal workings from well fluids through its unique construction. The metal-to-metal sealing integrity in the body joints and closure mechanism places it in a premium valve category while featuring an economical price. The simple, compact design enhances the valve's overall reliability and provides for trouble-free operation. Rod piston safety valves are available with working pressure rating to 10000psi.

Single Rod Piston Safety Valves are used a single rod piston with reliable spring-energized, no-elastomer dynamic seals; a stacic, full-closed, metal to metal seal. The valves are designed for general production with enhanced reliability and long life. The valves provide reduced OD, premium piston system, deep set design and many other optional features. Single Rod piston safety valves are available with working pressure rating to 10000psi and always be used in the wells with extreme down hole conditions.

Features and Benefits

• Simple, compact design

• Single Rod Piston type with Non-elastomer dynamic piston seals

• Rod Piston type with unique hydraulic actuation(single-piece piston/flow tube)

• Metal-to-metal seal in closed position

• Positive debris barrier at both ends of flow tube

• Flapper sealing verified to sand service (no resilient seal required)

• Minimized potential leak paths

•Optimum reliability

•Superior well containment and safety

• Critical component isolated from well environment

• Enhanced debris isolation and tolerance

Applications

• General production completion

• Hostile well environments in compatible with elastomer

Technical Data

Tubing Size | Max.OD | Internal Packing Bore | Pressure Rating | ||||

in. | mm | in. | mm | in. | mm | psi | MPa |

2 3/8 | 60.3 | 3.70 | 93.38 | 1.875 | 47.63 | 5,000 | 34.5 |

3.97 | 100.84 | 10,000 | 69.0 | ||||

2 7/8 | 73.0 | 4.65 | 118.11 | 2.125-2.312 | 53.98-58.72 | 5,000 | 34.5 |

4.74 | 120.24 | 10,000 | 69.0 | ||||

4.91 | 124.71 | 10,000 | 69.0 | ||||

3 1/2 | 88.9 | 5.20 | 132.08 | 2.562-2.812 | 65.07-71.42 | 5,000 | 34.5 |

5.37 | 136.40 | 10,000 | 69.0 | ||||

5.62 | 142.75 | 10,000 | 69.0 | ||||

4 1/2 | 114.3 | 6.73 | 170.94 | 3.750-3.812 | 95.25-96.82 | 5,000 | 34.5 |

6.97 | 177.04 | 7,500 | 51.7 | ||||

5 1/2 | 139.7 | 7.65-9.50 | 194.31-241.3 | 4.313-4.75 | 5000-10000 | 34.5-68.9 | |

7 | 177.8 | 8.375-10.50** | 212.7-266.7 | 5.75-6.00 | 5000-10000 | 34.5-68.9 | |

* Other profile and packing bore size available depending on tubing size selected and request.

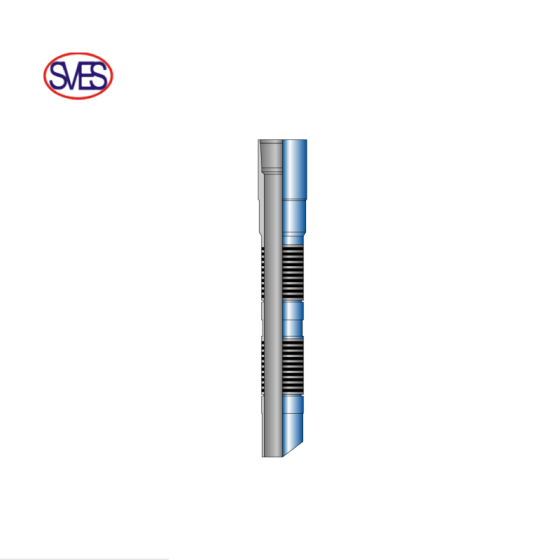

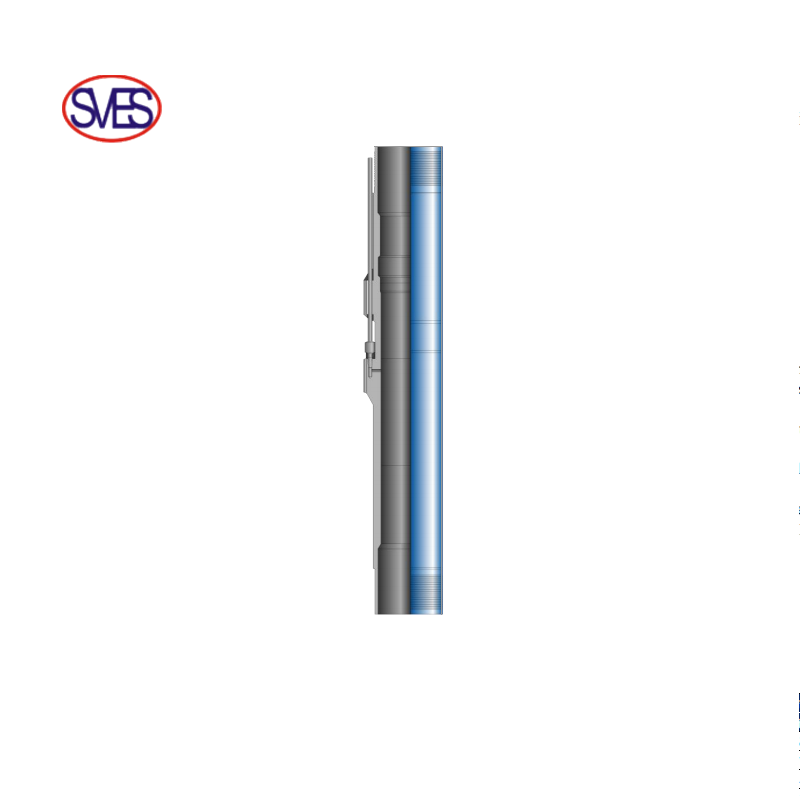

Safety Valve Landing Nipples are used to accommodate wireline retrievable sub surface safety valves. These nipples have a locking recess and a hydraulic communication port located between the two polished bores. This nipple features an integral control line connection port which operates Sub Surface Safety Valve. The nipple is a one-piece construction, manufactured from bar stock and contains the highly successful, field-proven lock profile.

Features and Benefit

• Large ID

• Offered in various combinations of lock profiles

• The lock profile enables completion optimization without restriction to standard seal bore sizes

• Manufactured from bar stock with an eccentric machine slug containing the control-line connection

• The nipple is constructed without welding, providing homogeneous material properties

• The 10,000-psi (68.9-MPa) working pressure with standard materials 9Cr or 13Cr, other materials available on request ensure application versatility

Applications

• Production and injection wells

Technical Data

Tubing Size | Tubing Weight | OD | Packing Bore | ||||

In. | mm | lb/ft | kg/m | in. | mm | in. | mm |

2 3/8 | 60.3 | 4.6 | 6.85 | 3.40 | 86.36 | 1.875 | 47.63 |

4.7 | 6.99 | 3.40 | 86.36 | ||||

2 7/8 | 73.0 | 6.4 | 9.52 | 4.22 | 107.19 | 2.312 | 58.72 |

6.5 | 9.67 | 4.22 | 107.19 | ||||

3 1/2 | 88.9 | 9.2 | 13.69 | 4.53 | 115.06 | 2.812 | 71.42 |

10.3 | 15.33 | 4.53 | 115.06 | 2.750 | 69.85 | ||

4 | 101.6 | 10.9 | 16.22 | 5.28 | 134.11 | 3.312 | 84.12 |

11 | 16.37 | 5.28 | 134.11 | ||||

4 1/2 | 114.3 | 12.6 | 18.75 | 5.56 | 141.22 | 3.812 | 96.82 |

12.75 | 18.97 | 5.56 | 141.22 | ||||

15.2 | 22.62 | 5.56 | 141.22 | 3.688 | 93.68 | ||

* Other profile and packing bore size available depending on tubing size selected and request.

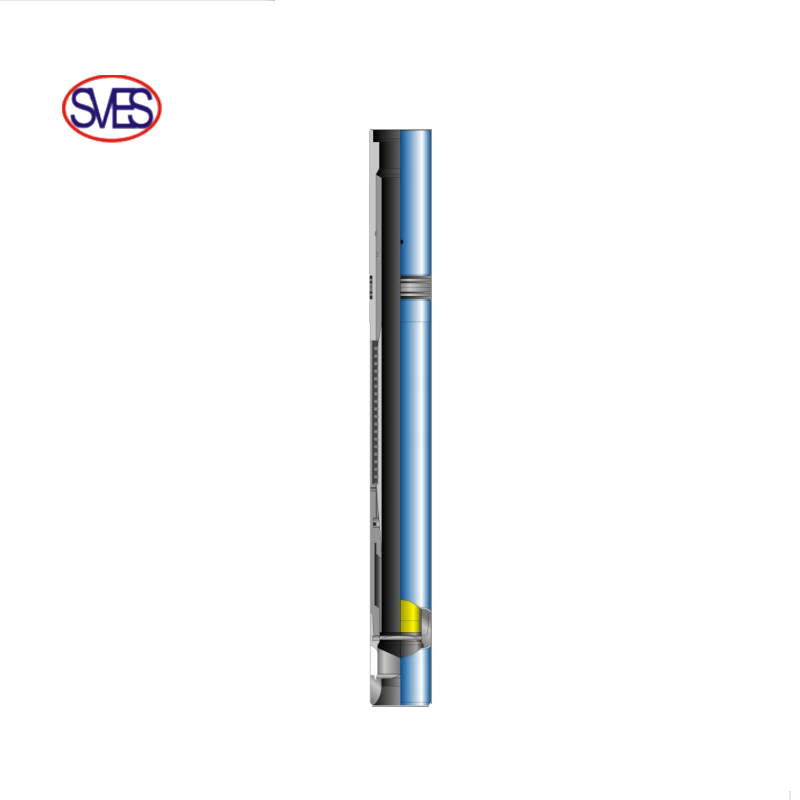

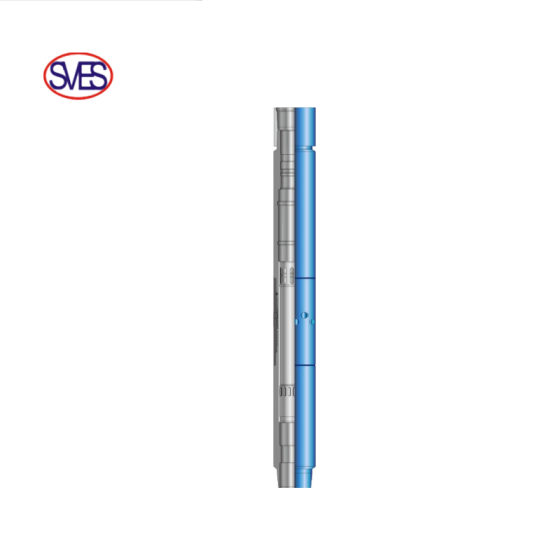

Wireline-Retrievable Safety Valves

Wireline-Retrievable Safety Valves offer premium features similar to a tubing retrievable safety valve and are landed in safety valve landing nipples that are equipped with a control line connected to the surface control system. This configuration enables the safety valve to be easily retrieved for repair or maintenance. When assembled to a wireline lock, the assembly can be installed in a safety valve nipple. Hydraulic control line connects the safety valve nipple to the surface emergency shut-down system. Loss of control line pressure will close the valve and shut-in the well. These wireline valves are premium valves due to the use of non-elastomeric seal material, metal-to-metal housing threads, high tensile strength metallurgy, and unique HP/HT packing and piston seal stacks when required by the application. These design features are imperative when considering applications for big bore, high temperature, high pressure, extremely corrosive, and hostile.

Features and Benefit

• Equalizing feature

• Large bore design

• Non-elastomeric dynamic seal assembly

• The lock profile enables completion optimization without restriction to standard sealbore sizes

• Easy field operation

• 10,000-psi working pressure

Applications

• Production and injection wells

Technical Data

Tubing Size | TUbing Weight | Valve ID | Nipple Seal Bore | ||||

In. | mm | lb/ft | kg/m | in. | mm | in. | mm |

2 3/8 | 60.3 | 4.6 | 6.85 | 0.75 | 19.05 | 1.875 | 47.63 |

4.7 | 6.99 | 0.75 | 19.05 | ||||

2 7/8 | 73.0 | 6.4 | 9.52 | 1.13 | 28.58 | 2.312 | 58.72 |

6.5 | 9.67 | 1.13 | 28.58 | ||||

3 1/2 | 88.9 | 9.2 | 13.69 | 1.52 | 38.61 | 2.812 | 71.42 |

10.3 | 15.33 | 1.52 | 38.61 | 2.750 | 69.85 | ||

4 | 101.6 | 10.9 | 16.22 | 1.75 | 44.45 | 3.312 | 84.12 |

11 | 16.37 | 1.75 | 44.45 | ||||

4 1/2 | 114.3 | 12.6 | 18.75 | 2.12 | 53.85 | 3.812 | 96.82 |

12.75 | 18.97 | 2.12 | 53.85 | ||||

15.2 | 22.62 | 1.89 | 48.00 | 3.688 | 93.68 | ||

5 1/2 | 139.7 | 17 | 25.30 | 2.56 | 65.02 | 4.562 | 115.87 |

23 | 34.23 | 2.25 | 57.15 | 4.437 | 112.70 | ||

7 | 177.8 | 35 | 52.09 | 3.38 | 85.85 | 5.875 | 149.22 |

* Other profile and seal bore size available depending on tubing size selected and request.