- Home

- >

- Products

- >

- Multi-stage Frac

- >

Multi-stage Frac

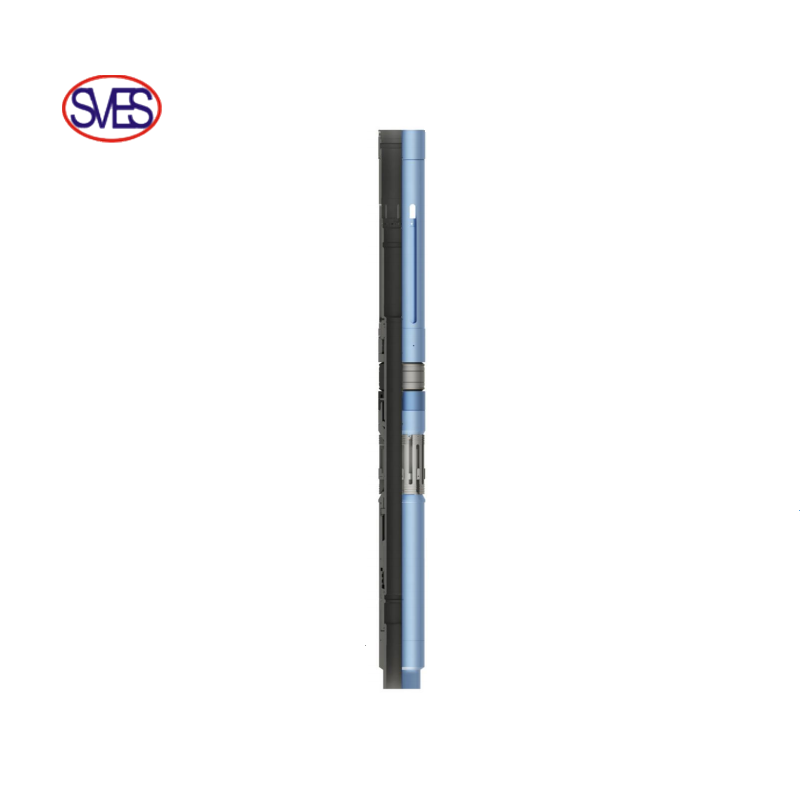

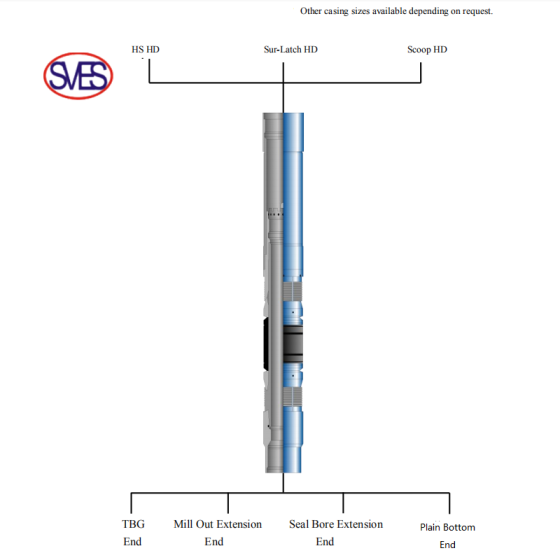

ABV Upper Seal Bore Retrievable Packer

ABV Upper Seal Bore Packer is a single string mechanical set production packer; it is designed for high pressure applications from above and below. The packer can be set by using a Hydraulic Setting Tool or in some cases an electric line tool with a setting adapter kit. To retrieve, the retrieving tool is stab in, pushed downward to latch on the packer, follow by straight pull to shear release the shear sleeve upward, this release the packer locking mechanism collapse the slips and continue upward pull will the packer out.

Features and Benefits

• Can be set to provide an anchor point in the well casing

• Polished upper bore function as a seal bore for a seal assembly

• Provides an upper connector for attachment to seal unit locators

• Diverts flow from the casing below the packer to the tubing above

• Provides a pressure isolation point in the casing

• Holds pressure from above and below once seals or a plug is installed

• Lower threaded connector to suspend tools or sand control screens

• Used with a range of other tools to achieve well completion objectives.

• Able to be milled if retrieval attempts fail.

• Full seal bore ID through the packer.

• Scoop Guide to guide tools and seals through the packer bore.

• Able to be logged on depth before setting.

Technical Data

Casing Size | Casing Weight | Max | O.D. | Mil | i I.D. | STD Connection | |||

in | mm | Lb/ft | Kg/m | mm | mm | in | mm | ||

7 | 177.8 | 23-29 | 34.23-43.16 | 6.00 | 152.4 | 38.4 | 98.55 | 4 1/2 LTC | 114.3 |

*Check with us with other size.

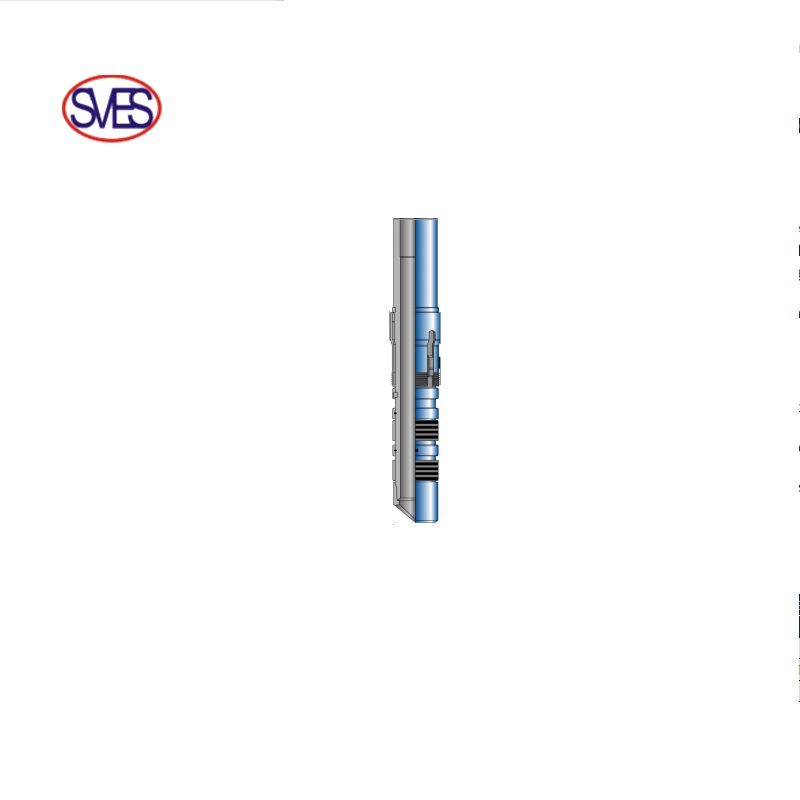

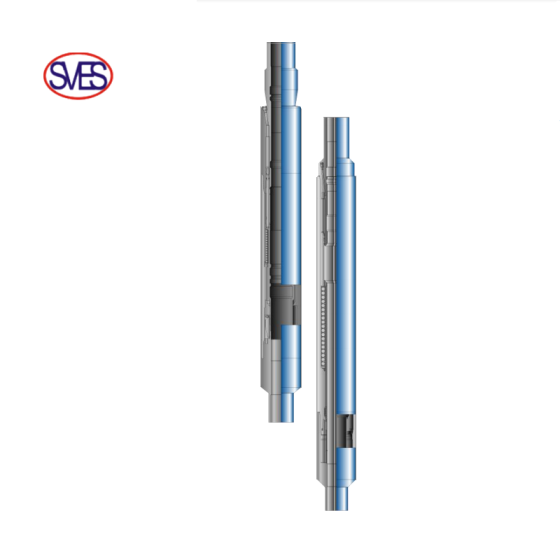

The Latch Seal Assembly is designed to be used with either the SLH, PRS or PPS Packer. The seal assembly incorporates heavy duty quadruple bonded seals and is run on the tubing after the packer has been set. The latch mechanism engages automatically with set down weight and disengages with right hand rotation while pulling tension.

Features and Benefits

• Prevents both upward and downward movement when latched

• Heavy duty bonded seals

• Available with premium elastomers

• Large bore ID

• Available in a wide range of materials and connections

• Standard 10ksi rate

Technical Data

Casing Size | Packer Bore | Max | O.D. | Min | LD. | STD Connection | |||

in | mm | in | mm | in | mm | mm | in | mm | |

7 | 177.8 | 3.88 | 98.55 | 4.545 | 115.44 | 2.97 | 75.44 | 3 1/2 EUE | 88.9 |

7 | 177.8 | 4.75 | 120.65 | 5.880 | 149.35 | 3.88 | 98.55 | 4 1/2 LTC | 114.3 |

9 5/8 | 244.5 | 6.00 | 152.4 | 8.220 | 208.79 | 4.25 | 107.95 | 5 1/2 LTC | 139.7 |

*Check with us with other size

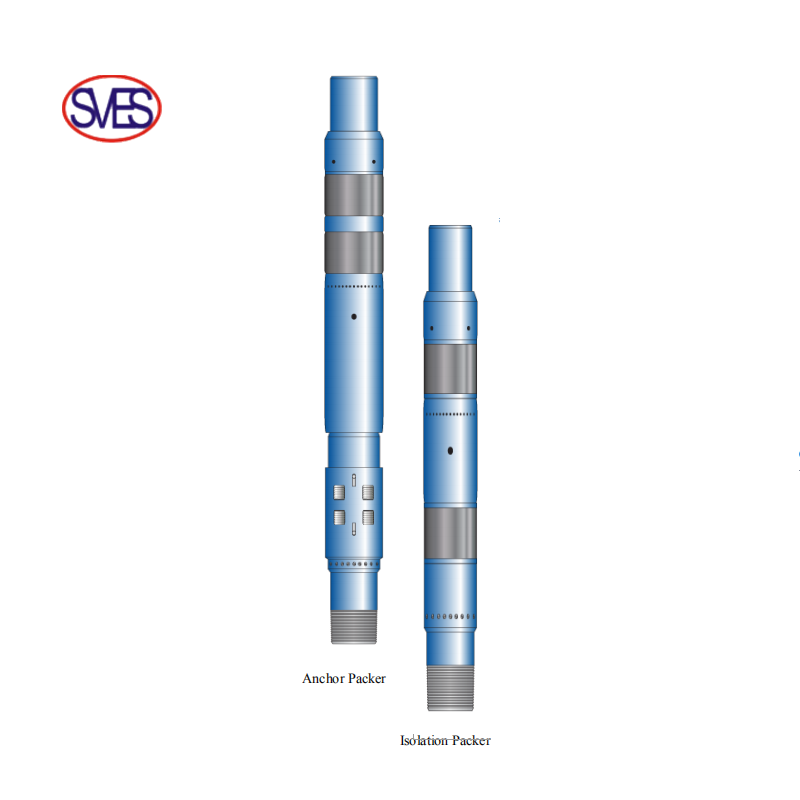

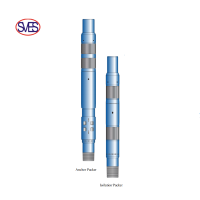

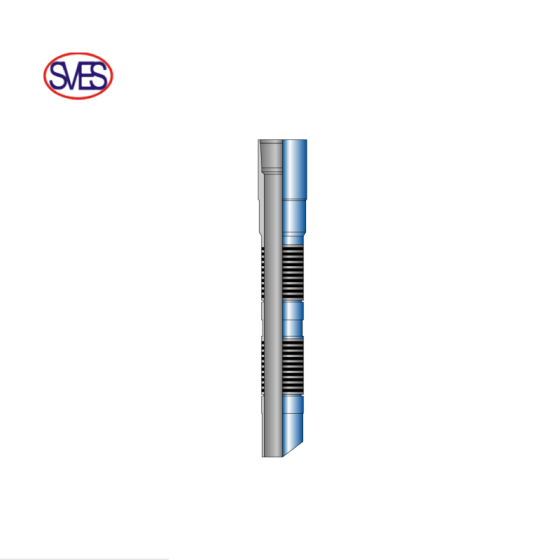

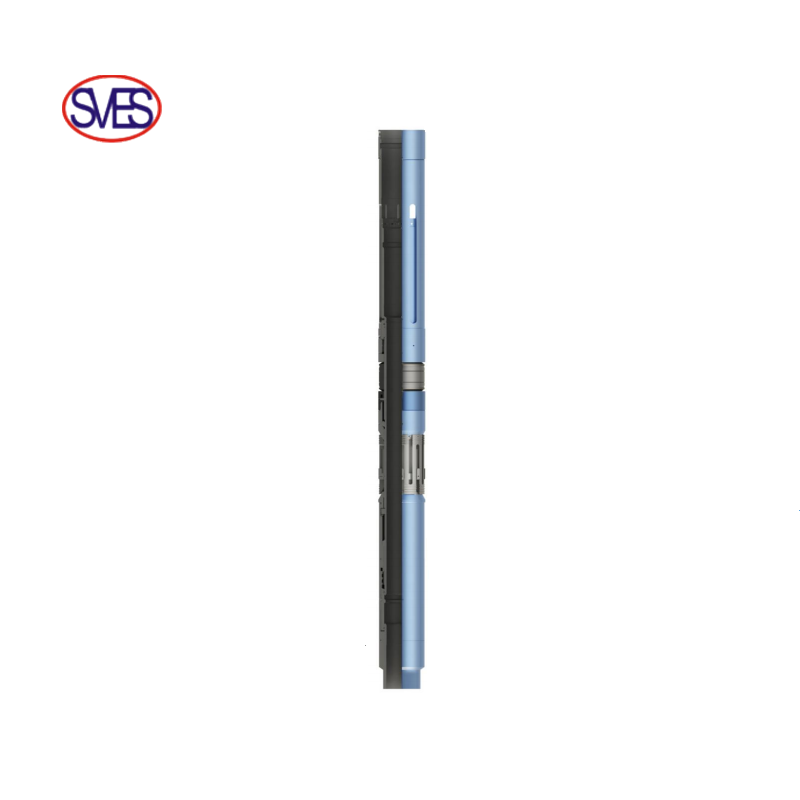

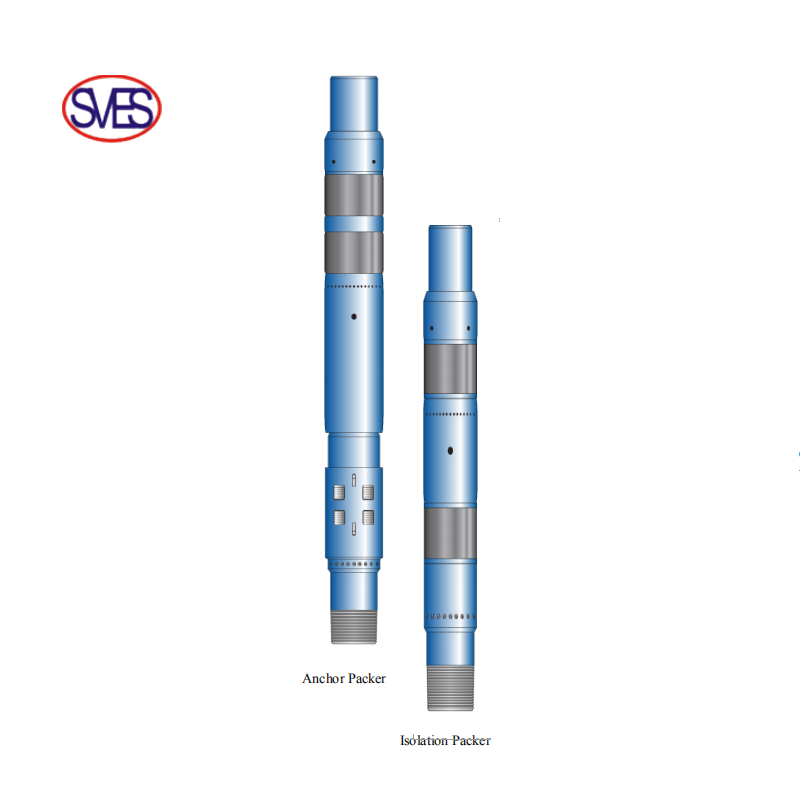

HPP Dual Element Open Hole Anchor /IPP Isolation Packer

The HPP open hole packer is designed to be run in either cased or open hole applications in vertical or horizontal wells for multi-stage frac application. The Anchor Packer incorporates a one piece bi-directional slip system in order to help prevent movement during higher pressure operations whereby the Isolation Packer is a non-anchoring packer. The Anchor can be ran as a single zone application packer or ran in conjunction with several packers in a multiple zone completion. Typically, on multiple zone horizontal open hole applications the Anchor packer would be used as the toe packer and/or makes the Packer and the excellent alternatives to using inflatable packers.

Features and Benefits

• Dual Element to Seal reliable

• Outer components locked to prevent pre-set

• Anchor packer incorporates a bi-directional slip system

• Field adjustable setting pressure

• Field adjustable shear release

• Designed for cased hole or open hole

• Available with carbide slips

• Available in a wide range of materials and connections

• Available with premium elastomers

Vertical/horizontal applications

• Standard 10ksi rate

• Field proved reliable Isolation Packer

Technical Data

Max O.D. | Min I.D. | STD Connection | |||

in | mm | in | mm | in | mm |

4.282 | 108.76 | 2.38 | 60.30 | 2 7/8 EUE | 73.0 |

5.690 | 144.53 | 3.00 | 76.20 | 3 1/2EUE | 88.9 |

5.690 | 144.53 | 3.85 | 97.79 | 4 1/2 LTC | 114.3 |

6.822 | 173.28 | 4.85 | 123.19 | 5 1/2 LTC | 139.7 |

*Check with us with other size.

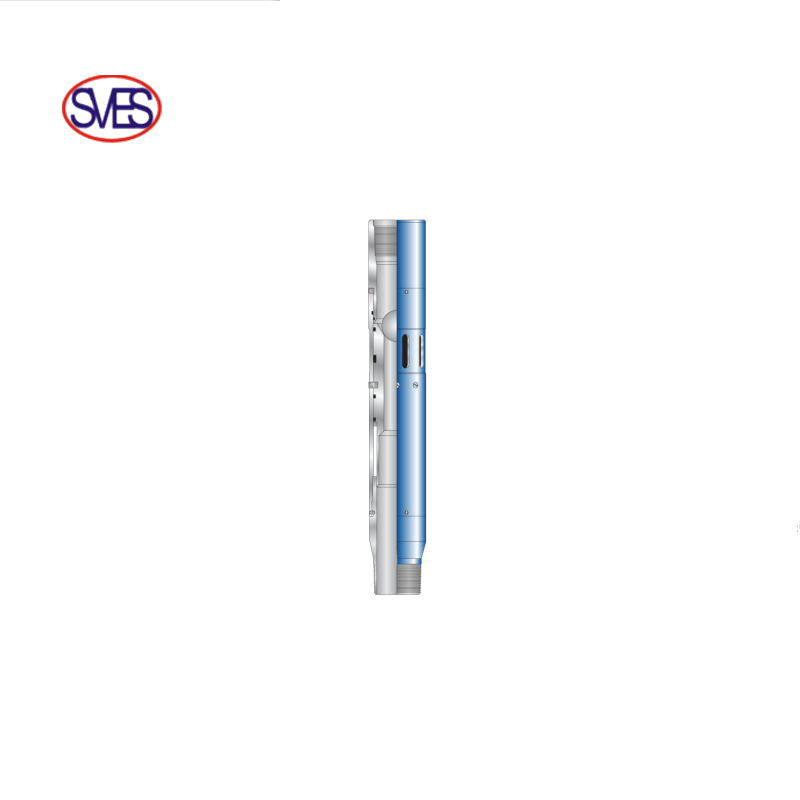

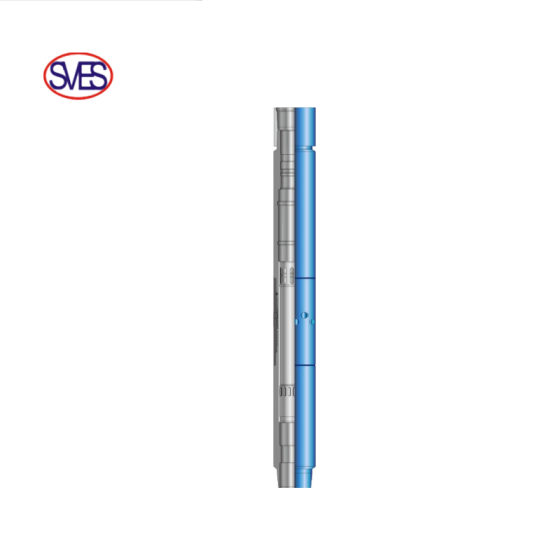

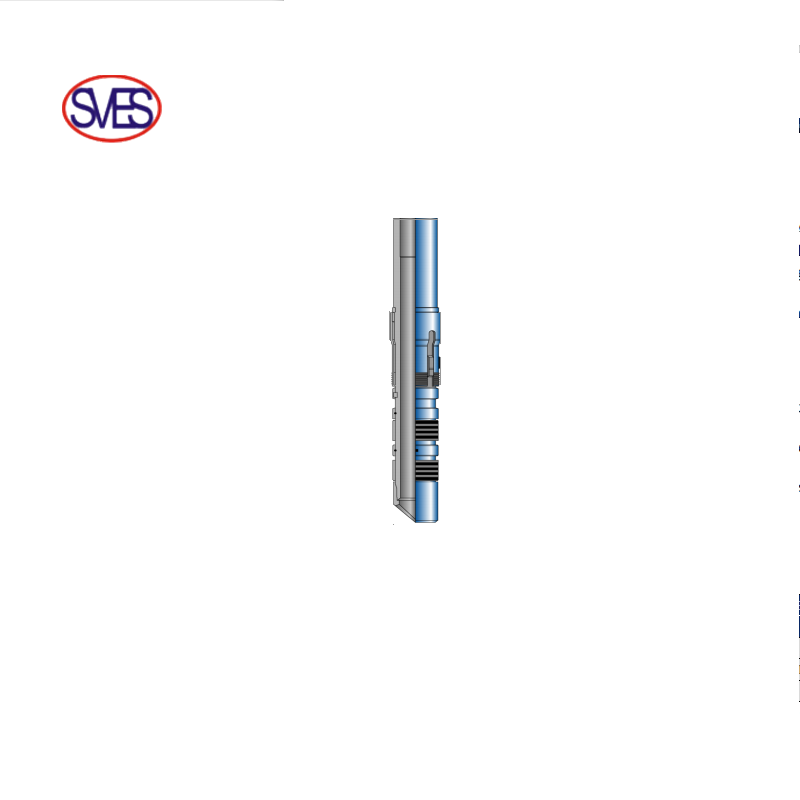

HFS Hydro-Activated Frac Sleeve

The HFS Hydro-Activated Frac Sleeve is designed for use when selectively stimulating multiple zones in either open or cased hole applications. The Hydro-Activated Frac Sleeve can be used in either horizontal or vertical wells and is usually the first valve ran in the well accompanied by multiple Frac Sleeve. The Hydro-Activated Frac Sleeve is hydraulically opened and an internal locking mechanism ensures the open position is securely maintained.

The Hydro-Activated Frac Sleeve is activated by field adjustable differential pressure from inside the sleeve across the actuation ports by a plugging device below, usually being the ball seat circulating sub.

The Hydro-Activated Frac Sleeve can be cemented in the hole and will reliably function as they have an isolated internal shifting mechanism. Once open, the sleeves have an internal locking mechanism to ensure the open position is securely maintained.

The Sleeve can be designed to has external fins across the frac ports to minimize the cement thickness between the sleeve and the formation.

Features and Benefits

• Internal locking mechanism

• Field adjustable opening pressure

• Suitable for high pressure applications

• Designed for both horizontal and vertical applications

• Designed for multiple zone applications

• Full bore ID

• Available in a wide range of materials and connections

• Standard 10ksi rate

Technical Data

Max O.D. | Min I.D. | STD Connection | |||

in | mm | in | mm | in | mm |

4.282 | 108.76 | 2.38 | 60.30 | 2 7/8 EUE | 73.0 |

5.690 | 144.53 | 3.00 | 76.20 | 3 1/2EUE | 88.9 |

5.690 | 144.53 | 3.85 | 97.79 | 4 1/2 LTC | 114.3 |

6.822 | 173.28 | 4.85 | 123.19 | 5 1/2 LTC | 139.7 |

*Check with us with other size。

PFS Ball-Activated Frac Sleeve

The PFS Ball-Activated Frac Sleeve is designed for selectively stimulating multiple zones in either open or cased hole applications. The Ball-Activated can be used in either vertical or horizontal wells usually in conjunction with the Hydro-Activated Frac Sleeve and HPP Packers. The Ball-Activated Frac Sleeve is activated by circulating a ball into a drillable seat inside the tool. Applied differential pressure from above the ball seat shifts the internal piston downward opening up the frac ports. The Ball-Activated sleeve has an internal locking mechanism keeping the piston locked securely in place after it has been shifted. The standard Ball-Activated piston is made out of an easily drillable material.

Features and Benefits

• Field adjustable opening pressure

• Internal locking mechanism

• Suitable for high pressure applications

• Designed for horizontal and vertical applications

• Designed for multiple zone applications

• Easily drillable ball seat

• Available in a wide range of materials and connections

Technical Data

Max O.D. | Min I.D. | STD Connection | |||

in | mm | in | mm | in | mm |

4.282 | 108.76 | 2.50 | 63.50 | 2 7/8 EUE | 73.0 |

5.690 | 144.53 | 3.00 | 76.20 | 3 1/2 EUE | 88.9 |

5.690 | 144.53 | 3.87 | 98.30 | 4 1/2 LTC | 114.3 |

6.822 | 173.28 | 5.00 | 127.00 | 5 1/2 LTC | 139.7 |

*Check with us with other size。

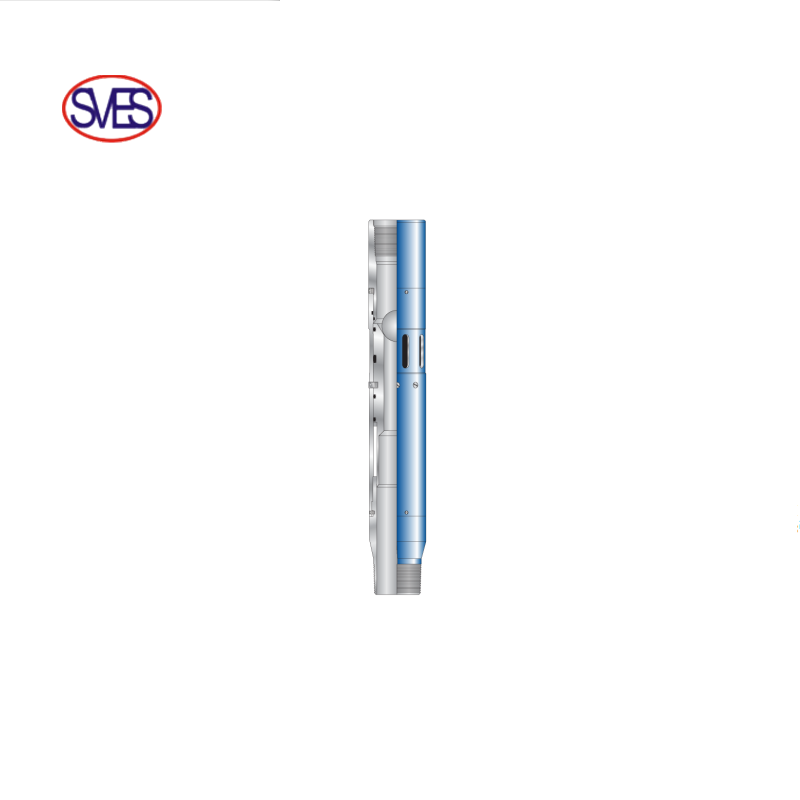

PFS-1Advanced Ball-Activated Frac Sleeve

The PFS-1 Advanced Ball-Activated Frac Sleeve has all the proven features of the conventional Ball-Activated Frac Sleeve with the additional benefit of selective zone isolation. The Advanced Frac Sleeve is ran as part of the conventional Multi-Stage Frac system and after the sleeve is opened utilizing ball drop technology, the piston can then be drilled out and the sleeve can be closed/opened using the activation tool on coil.

Features and Benefits

• Can be closed/opened with coil ran activation tool

• Field adjustable setting pressure

• Designed for multiple zone applications

• Internal locking mechanism

Technical Data

Max O.D. | Min I.D. | STD Connection | |||

in | mm | in | mm | in | mm |

5.69 | 144.53 | 3 | 76.2 | 3 1/2EUE | 88.9 |

5.69 | 144.53 | 3.76 | 95.5 | 4 1/2 LTC | 114.3 |

6.822 | 173.28 | 4 | 101.6 | 5 1/2 LTC | 139.7 |

*Check with us with other size。

In order to activate each sleeve, a properly sized ball is pumped along with a fracturing fluid inside the well. Each ball is smaller than the opening of all of the previous sleeves, but larger than the sleeve it is intended to open. Seating of the ball exerts pressure at the end of the sliding sleeve assembly, causing it to slide and open the frac ports. Once the port is opened, the fluid is diverted into the open hole space outside of the completion assembly, causing the formation to fracture.

At the completion of each fracturing stage, the next larger ball is injected into the well, which open the next sleeve, and so on, until all of the sleeves are opened and multiple fractures are created in the well. The main advantage of this completion technique is the speed of operation which also reduces costs.

Typically, ball sizes are staged in .250" or .125" increments. It is important to understand that this process is not without risk of failure and should only be undertaken after considerable research and consideration. Frac plugs are designed to seal from above the plug only. Each plug uses a plastic fracturing ball that seals on top of the mandrel. The fracturing ball is free to float off the mandrel with pressure or flow from below the plug. This allows immediate flow back of all zones following treatment.

Technical Data

Ball Seat ID | Ball Size |

in | in |

0.905 | 1.000 |

1.030 | 1.125 |

1.155 | 1.250 |

1.280 | 1.375 |

1.405 | 1.500 |

1.530 | 1.625 |

1.655 | 1.750 |

1.780 | 1.875 |

1.905 | 2.000 |

2.030 | 2.125 |

2.155 | 2.250 |

2.280 | 2.375 |

2.405 | 2.500 |

2.530 | 2.625 |

2.655 | 2.750 |

2.780 | 2.875 |

2.905 | 3.000 |

3.030 | 3.125 |

3.155 | 3.250 |

3.280 | 3.375 |

3.405 | 3.500 |

3.530 | 3.625 |

3.655 | 3.750 |

3.800 | 4.000 |

4.050 | 4.250 |

4.300 | 4.500 |

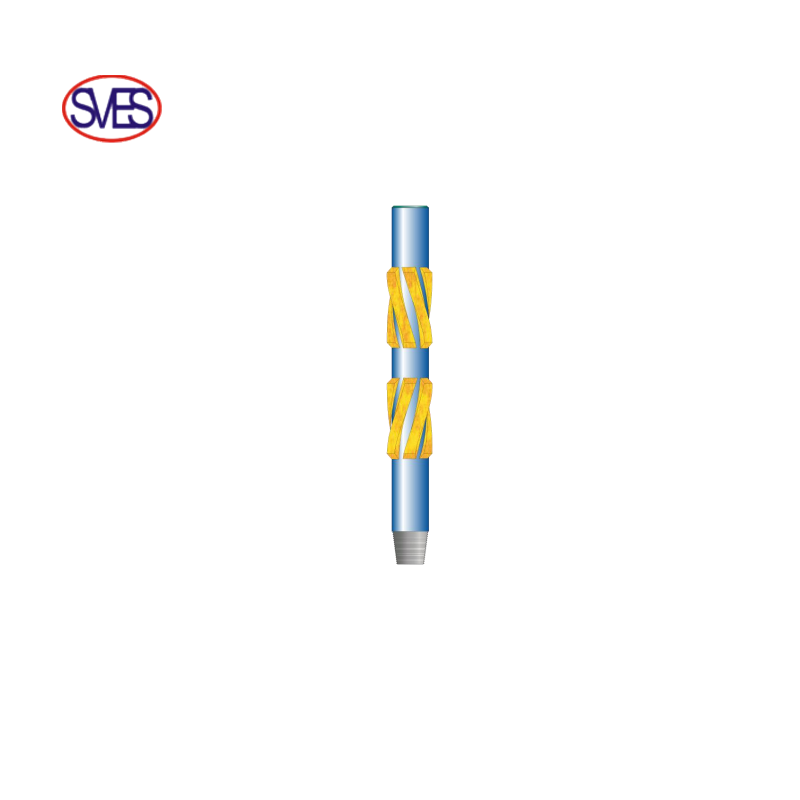

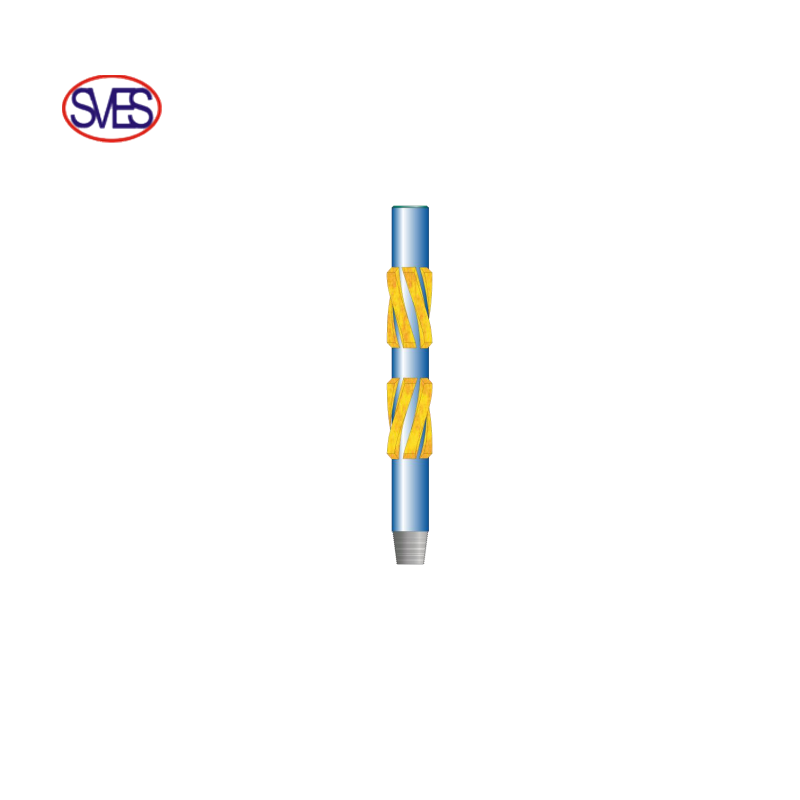

The Open Hole Reamer is generally ran in order to dress out the open hole before installing Multi-Stage Frac systems.

The Reamer is a rigid heavy duty one-piece tool with 2 sets of 12 opposing tungsten carbide capped spiraled blades with an OD close to hole tolerances in order to best prepare the well bore ID properly before running Multi-Stage Frac systems.

Features and Benefits

• Heavy duty one piece design

• 2 sets of 12 tungsten carbide blades

• Close O.D. to open hole tolerance

Technical Data

Max O.D. | Min I.D. | STD Connection | |||

in | mm | in | mm | in | mm |

4.650 | 118.11 | 1.50 | 38.1 | 2 7/8 IF | 73.03 |

5.950 | 151.13 | 2.00 | 50.8 | 3 1/2 IF | 88.90 |

6.000 | 152.40 | 2.00 | 50.8 | 3 1/2 IF | 88.90 |

7.700 | 195.58 | 2.00 | 50.8 | 3 1/2 IF | 88.90 |

8.500 | 215.90 | 3.00 | 76.2 | 4 IF | 101.60 |

*Check with us with other size.

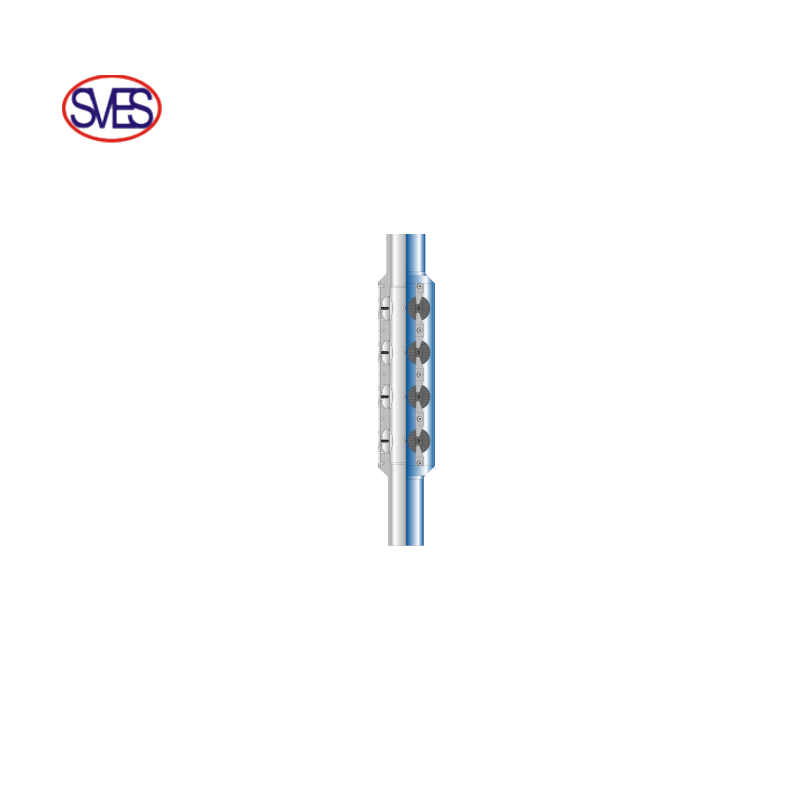

The Open Hole Centralizer is mainly used with Open Hole Packers, generally as part of the Multi-Stage Frac System. The Centralizer helps to protect the packers from damage during equipment installation in the open hole section of the well bore as well as helping to centralize the packers during the setting procedure. The Centralizer freely swivels to allow for rotation when running in the hole if required and has spiraled grooves to ensure good circulation.

Features and Benefits

• Helps prevent running damage

• Centralizes when setting

• Available in composite or steel

• Swivels to allow for tool string rotation

Technical Data

Open Hole Size | Max O.D. | STD Connection | |||

in | mm | in | mm | in | mm |

6 | 118.11 | 5.8 | 147.32 | 3 1/2 EUE | 88.9 |

6 1/8 | 155.58 | 5.812 | 147.62 | 3 1/2 EUE | 88.9 |

6 1/8 | 155.58 | 5.812 | 147.62 | 4 1/2 LTC | 114.3 |

6 1/4 | 195.58 | 5.93 | 150.62 | 3 1/2 EUE | 88.9 |

6 1/4 | 151.13 | 5.93 | 150.62 | 4 1/2 LTC | 114.3 |

7 7/8 | 200.03 | 7.5 | 190.5 | 5 1/2 LTC | 139.7 |

8 1/2 | 215.9 | 8.16 | 207.26 | 6 5/8 LTC | 168.3 |

*Check with us with other size.

The Tubing Anchor is a reliable, retrievable double grip anchor catcher which prevents tubing string from excessive movement in tension, compression, or rotation during pumping operation increasing pump efficiency and decreasing rod and tubing wear.

Features and Benefits

• Efficient and reliable anchor system

• Available for H2S and CO2 compatibility

• Easy to redress

Technical Data

Casing Size | Casing Weight | Max OD | Min ID | Connection | |||||

in | mm | lb/ft | Kg/m | in | mm | in | mm | in | mm |

5 1/2 | 139.7 | 13-17 | 19.3-25.3 | 4.63 | 117.60 | 2.44 | 61.98 | 2 7/8 EUE | 73.0 |

5 1/2 | 139.7 | 20-26 | 29.8-38.7 | 4.52 | 114.80 | 2.44 | 61.98 | 2 7/8 EUE | 73.0 |

7 | 177.8 | 17-20 | 25.3-29.76 | 6.26 | 159.00 | 2.98 | 75.69 | 3 1/2 EUE | 88.9 |

7 | 177.8 | 23-38 | 34.23-56.55 | 5.82 | 147.83 | 2.98 | 75.69 | 3 1/2 EUE | 88.9 |

*Check with us with other size.

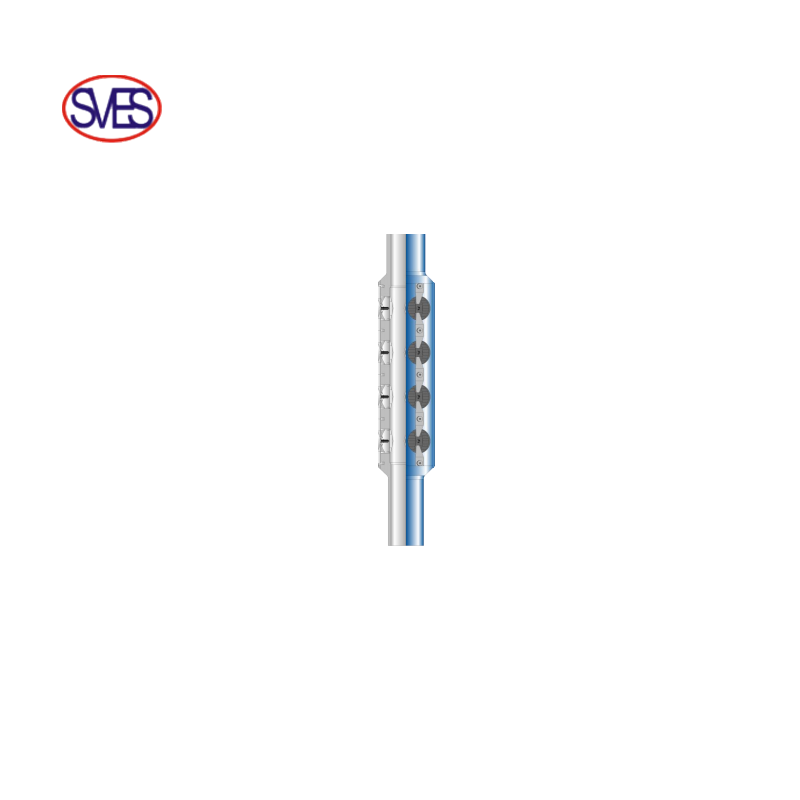

The Ball Seat Circulating Valve is designed to be a reliable closeable circulation port generally ran at the bottom of a tool string in either cased or open hole for vertical or horizontal well completions. Once the tool string is in place and the required circulation operation is complete a ball is circulated onto the seat, an adjustable pre-determined pressure is applied and an internal sleeve shifts downwards which closes the internal circulating ports. Once the sleeve has been shifted a positive locking mechanism ensures it is securely maintained in place.

Features and Benefits

• Internal secure locking mechanism

• Adjustable closing pressure

• Designed for both horizontal and vertical applications

• Designed for both cased and open hole applications

• Available in a wide range of materials and connections

Technical Data

Max O.D. | STD Connection | ||

in | mm | in | mm |

2.28 | 57.91 | 2 7/8 EUE | 73 |

5.42 | 137.67 | 3 1/2 EUE | 88.9 |

5.42 | 137.67 | 4 1/2 LTC | 114.3 |

6.51 | 165.35 | 5 1/2 LTC | 139.7 |

*Check with us with other size.

The Float Shoe attaches to the lowest end of the casing string and is used to guide the casing or line into the wellbore. The check-valve assembly within the float shoe prevents the flow of fluids into the liner during the running process or following the circulation operation. Customers can request any casing grade and premium thread by special order.

Features and Benefits

• Single or dual poppet valves

• All internal parts PDC drillable

• 50,000 psi through 125,000 psi yield strengths are standard

• API RP 10F category IIIC compliant

• Cement nose standard, bladed bottom available.

The King Frac System delivers unprecedented flexibility for multistage completions. There is no practical limit to the number or spacing of stages. It also isolates and stimulates multiple stages in a single trip on coiled tubing and is typically used in Cased hole. This Hydraulic Jet Frac System works in both horizontal and vertical wellbores. Tool string depth is correlated to desired perforation depth by using a mechanical casing coupling locator. Starting with the lowest stage, the Packer is set to isolate the zone from wellbore below the packer. Then the abrasive slurry is pumped down the coiled tubing string to the Hydraulic Jet Unit. The high-velocity jets cut through the casing and cement and into the formation. After perforating, a leading-edge fluid such acid can be circulated or injected down the coiled tubing/casing annulus. Then the frac is also pumped down the annulus. If screenout occurs, excess sand can be quickly reverse circulated out. Finally, a pull on the coiled tubing unsets the packer, which is then moved up to the next perforation point, where the sequence is repeated.

Features and Benefits

• Simple design and most efficient

• Unlimited stages and spacing

• Precise frac location

• Water and chemical reservation

• Unrestricted, production-ready wellbore after frac.

• When annular fracturing, the coiled tubing serves as a deadleg for monitoring actual pressure at the frac point to assist in adjusting pad size, sand concentration and ramp, fluid viscosity and pump pressure in real time

• When screenout occurs, excess sand can be quickly reverse-circulated out without tripping out of the hole

• Equalizing valve allows movement without flowing the well

• Hydraulic disconnect unit enables emergency release

• Less hydraulic horsepower needed

• 5 minutes between Fracs. The simple operation of the Multistage Unlimited system cuts the time between fracs to as little as 5 minutes.

• Less equipment, less exhaust, smaller footprint. Environmentally friendly fracturing.