- Home

- >

- Products

- >

- Packer Accesories

- >

Packer Accesories

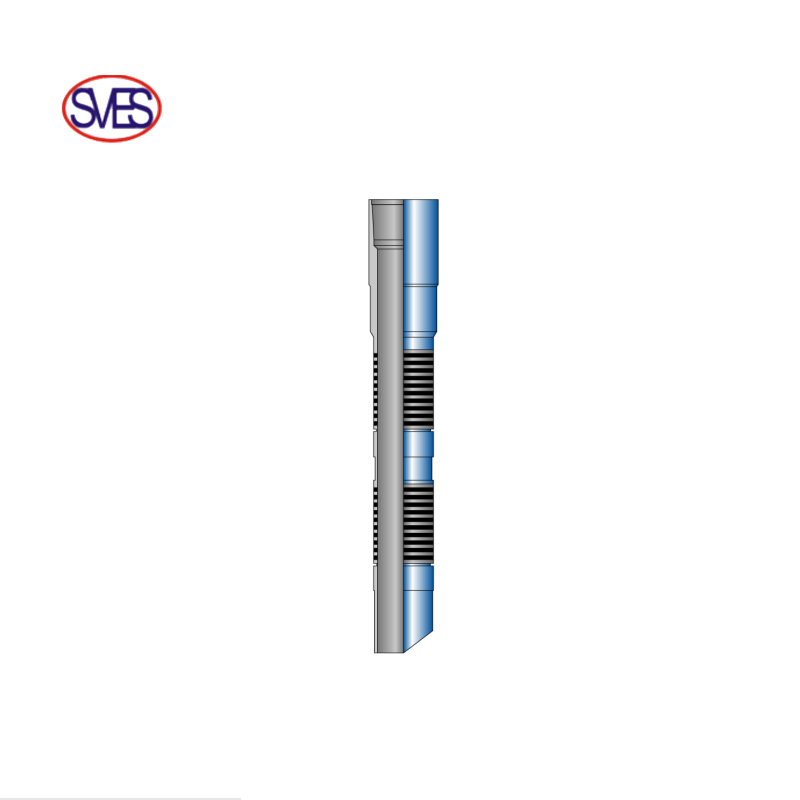

The Locator Seal Assembly is used when it is not desirable to anchor the seals into the packer. The Locator Seal Assembly allows movement of the seals in response to pressure and temperature changes on the tubing string. Force changes tending to elongate the tubing string are transferred through the locator into the packer and casing. Seals are dynamic and must be designed to accommodate sliding or reciprocation, in addition to temperature and wellbore fluids. The Locator Seal Assembly is retrieved by straight pick-up.

Anchor Seal Assemblies lock, or anchor, into the packer top and seal in the bore of the packer or seal bore extension below the packer. The anchor seal assembly transfers tubing forces through the anchor into the packer; the seals are static and are only subjected to pressure differentials.

The anchor seal assembly consists of the seal mandrel, seal units as required, a re-entry guide bottom and a latch mechanism and locator. In some cases, a spacer tube is used to properly position the seals within the seal bore. The anchor seal assembly is released by right-hand rotation.

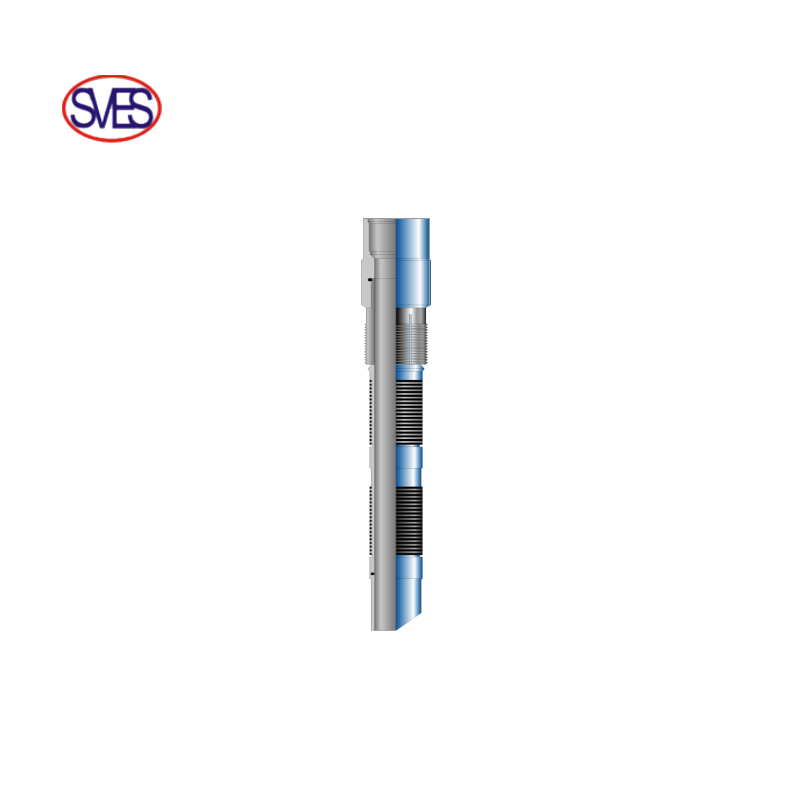

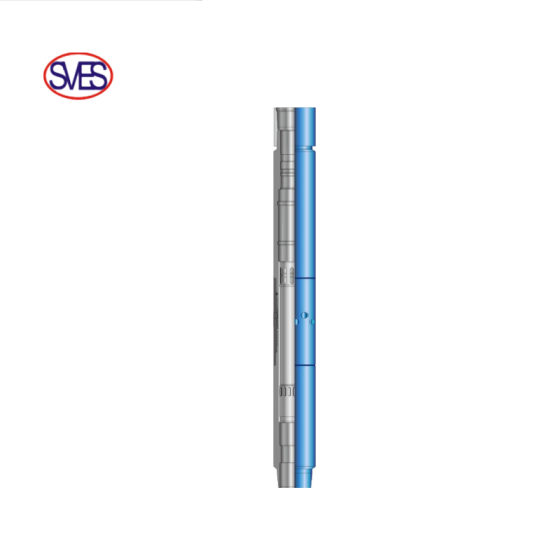

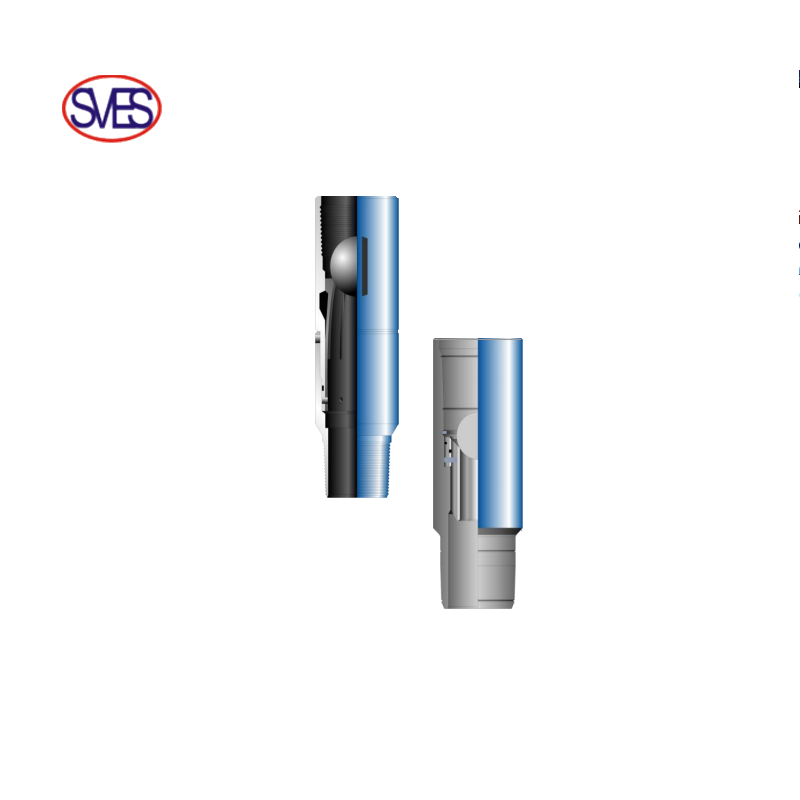

Sur-Latch Shear Release Seal Unit Assembly

The Sur-Latch Shear Release Seal Unit Assembly is used with Seal Bore Packers. The seal unit provides a tubing-to-packer seal, a positive locking condition, for tubing left hand rotational release or straight pull shear release. The seal unit assembly is made up to the lower most part of the tubing string at the surface if a wireline-set packer is used. If a hydraulic packer is used, the seal unit assembly may be installed into the packer at the surface and RIH. The seal unit packing contacts the mating hone bore in the packer to form a seal. The floating latch moves up enough to allow its collet-type ends to flex inward. This allows the mating left-hand threads engaged in the packer. To release, a straight pull above the predetermined force will shear the shear pins, allow the latch to move downward and collapsed inward, disengaged from the packer head. Alternatively, by right hand rotational method with a tensile force 1,000 to 1,500 lb force.

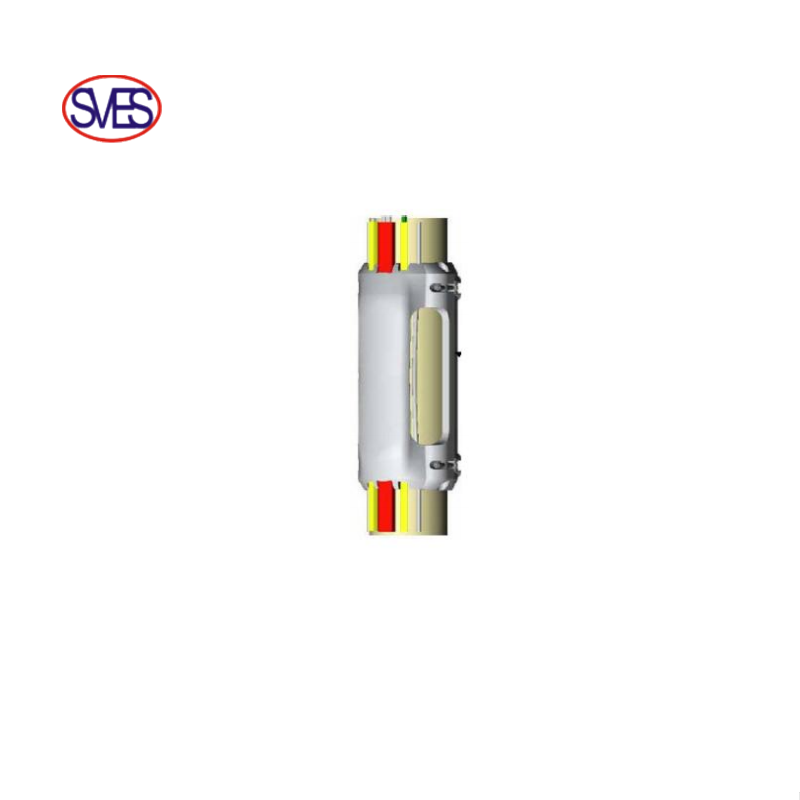

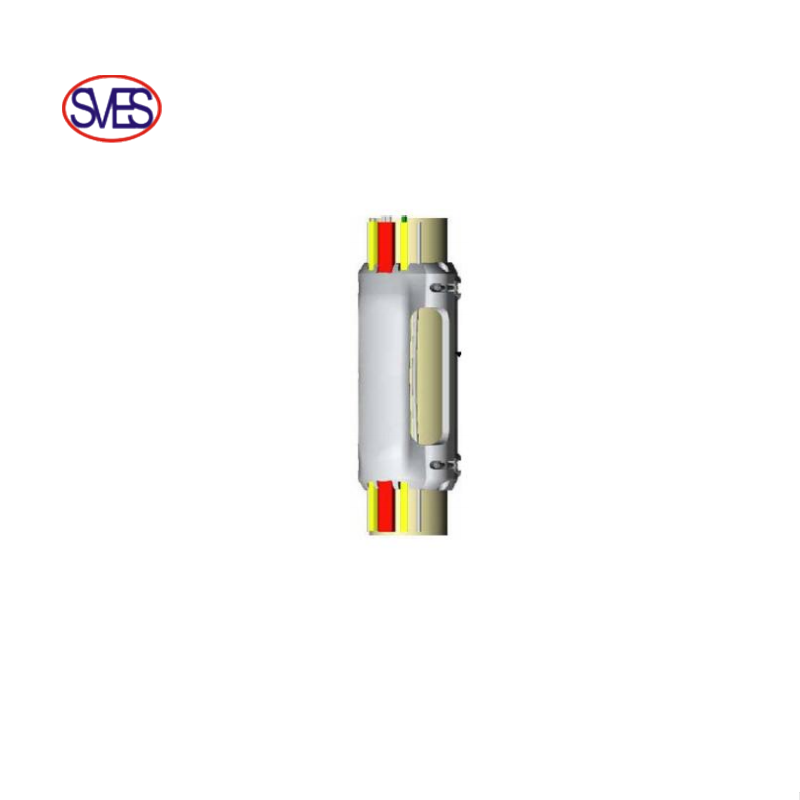

The Gas Vent Valve is designed to be threaded onto ESP packer and vent the gas to maintain optimum fluid levels for the ESP. It is a control line actuated valve from surface. The valve is opened by applying hydraulic control pressure, and closes when the pressure is released.

Features and Benefits

• Controlled by hydraulic control-line pressure

• Sealing reliable and long service life

• Large flow area

• Two sizes: 1” and 1 1/2”,c/w 1/4” NPT connection

• 5000psi working pressure rating

The Cable Pack-Off provides an effective seal for an electrical submersible pump (ESP) cable when used with a multistring packer. To achieve a seal, the metal shield on the cable is removed from a short section, and the cable is installed through the secondary side of the ESP packer. The tool isolates pressure below from pressure above the packer by sealing on the rubber jacket of the cable.

Features and Benefits

• Compression energized elastomeric seals

• Without splicing or using expensive penetrators when running cable through the packer

• Seals on cable OD, designs available for round and flat cables

• Simple tighten of a nut to compress the elastomers

• Standard 3000psi working pressure rating

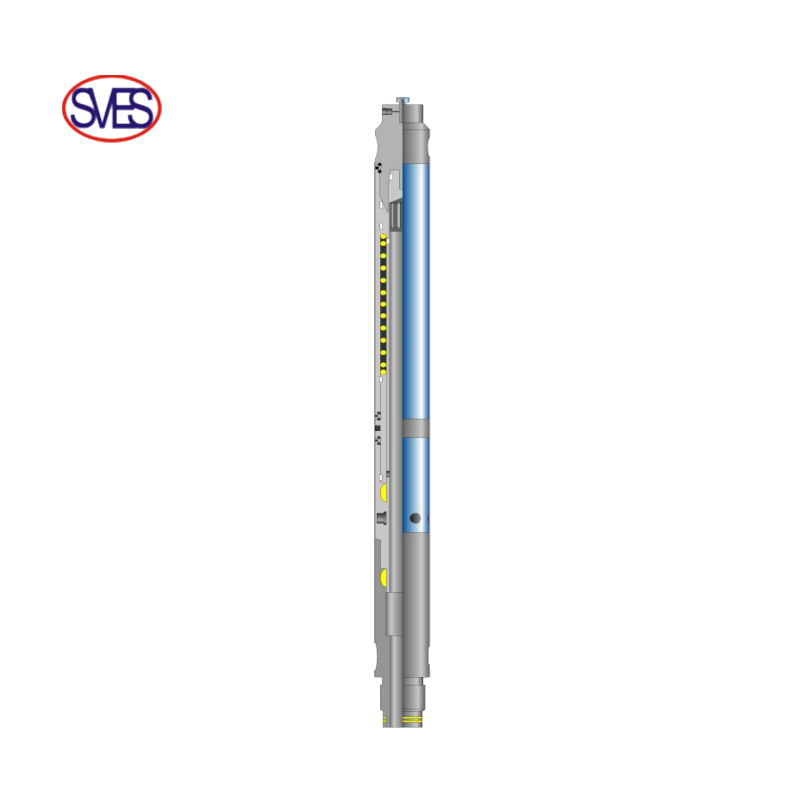

The Y-Tool is designed to be run with ESP below ESP packer. As the produced fluid leaves the ESP it flows through a pump sub and then joins the main production string through the Y-Tool profile that has been carefully designed to minimize flow erosion. The Y-Tool offsets the ESP in the well to provide a straight line conduit for wireline or coiled tubing tools to bypass the ESP. The Y-Tool has an upper connection for the production tubing and two lower connections, one for the ESP and the other for the bypass. A blanking plug is located in the bypass side in a special nipple to prevent recirculation of the pumped fluid. The blanking plug is removed prior to and after intervention. For logging operations, the blanking plug is replaced by a logging plug which allows real time or memory logging to be conducted whilst the pump is operating.

Features and Benefits

• Large flow area

• Minimize flow erosion

• Simple design

• Standard 2 3/8”, 2 7/8” and 3 1/2” sizes

Control line and Cable Protectors

The Control Line and Cable Protectors fix the cable on tubing, and it protects the cable. The tubing supports the control line and cable and ensures they not be destroyed while running the string. Consequently, the control line and cable could be used again and the cost is reduced. Negative effects would occur if the cable were not protected while running the string. Such as attrition, changing pump and well repair work. Especially the big diameter cables are more easily damaged at the coupling.

Features and Benefits

• Different size for tubing

• Anticorrosion material capable

• Special tools for right installation

• Record the torque and position

• Guard against falling objects

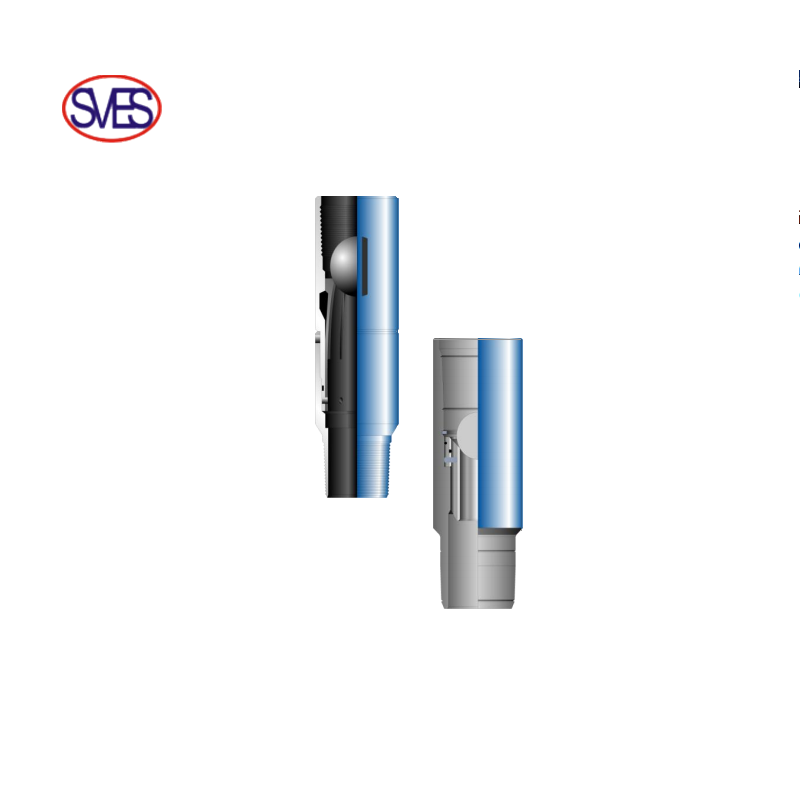

The Model Hydro Trip Pressure Sub is a pressure actuated device installed in tubing string below a hydrostatically actuated tool such as a Hydraulic set packer. It provides a method of applying pressure to activate and set the packer and then through continued pressure, activate the Hydro Trip Sub. Packer is set by circulating a ball through packer down to ball seat in the Hydro Trip Sub.

After packer is set, a continued increase in pressure is applied to shear the shear screws in the shear ring, allowing the ball seat collet to move down into the collet relief area and allowing the ball to pass down the Hydro Trip Sub through the tubing, leaving a “full open” Sub with no restrictions to production. The Collet Catcher Sub is used when any restrictions are installed below, ball and solid bar are available.

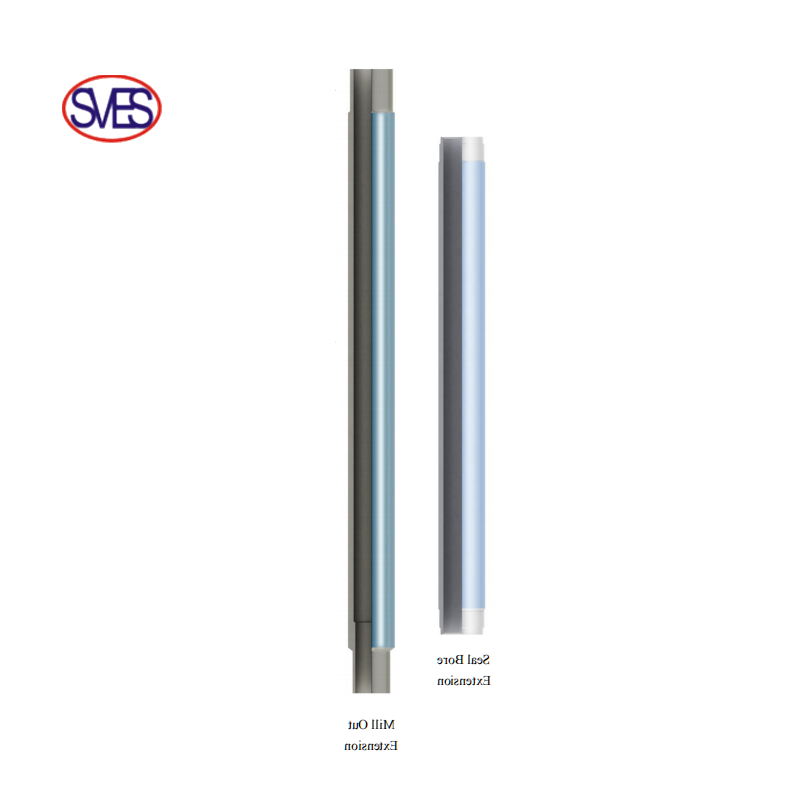

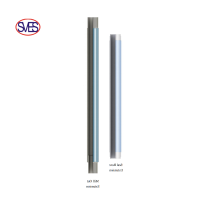

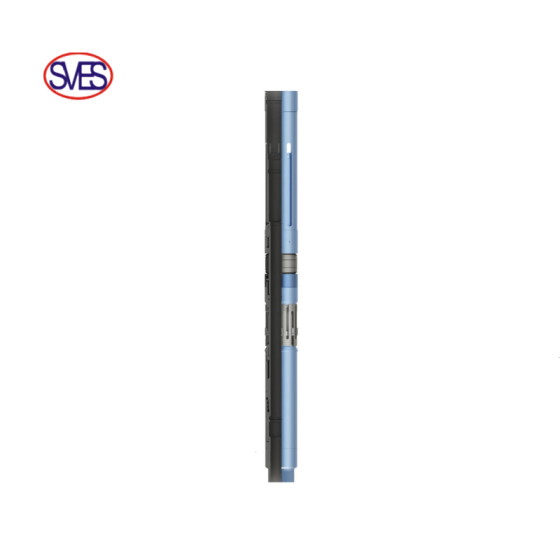

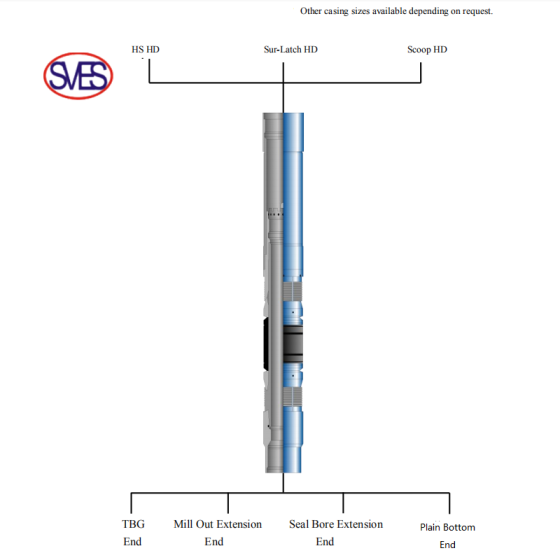

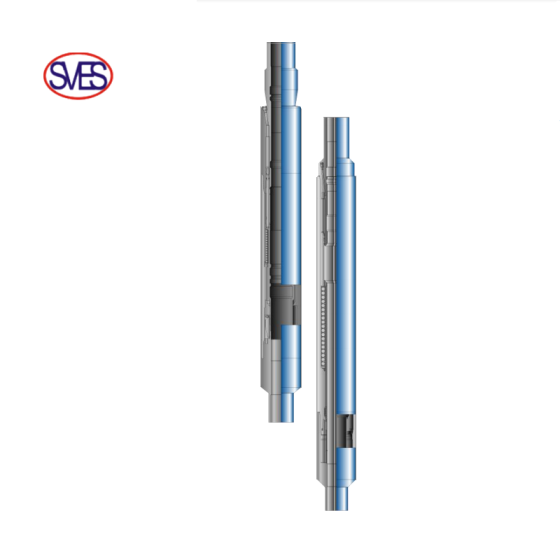

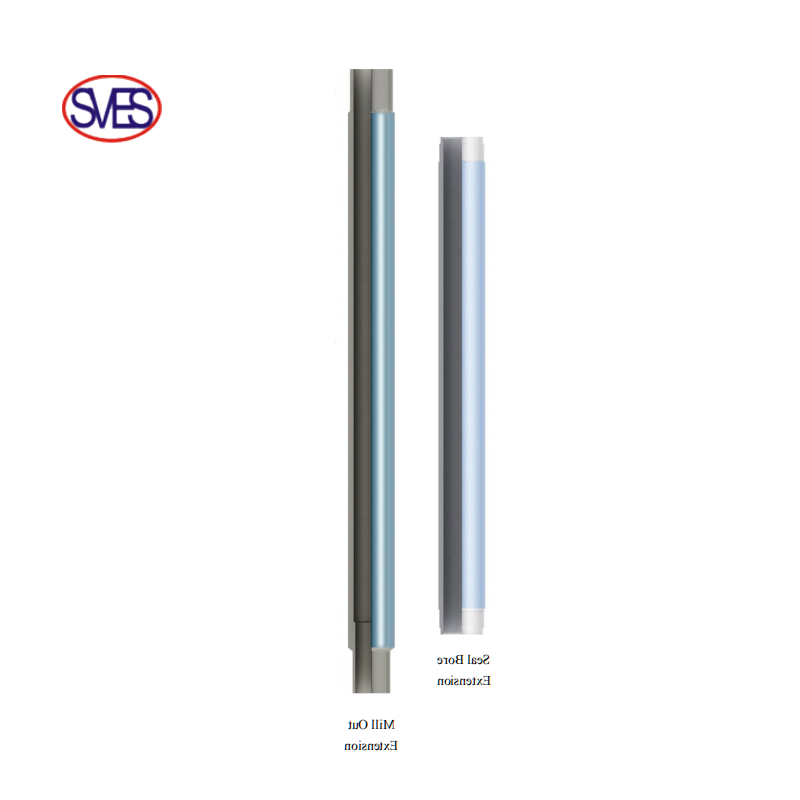

Seal Bore Extension & Mill Out Extension

The Seal Bore Extension are generally used in installations where floating s「' required due to excessive tubing contraction. The Seal Bore Extensions have tl sealing bore ID as the corresponding packer to allows a continuous seal bore for the lower most seals of a long seal assembly. The Seal Bore Extensions are available in a variety of lengths.

The Mill Out Extension are designed for use with seal bore packers in installations where a larger inside diameter is required to accommodate the latching mechanism of packer retrieval tools. The mill out extension has a slightly larger ID than the corresponding packer to allow the packer retrieval tool to latch. Mill out extension are available in a variety of lengths and materials.

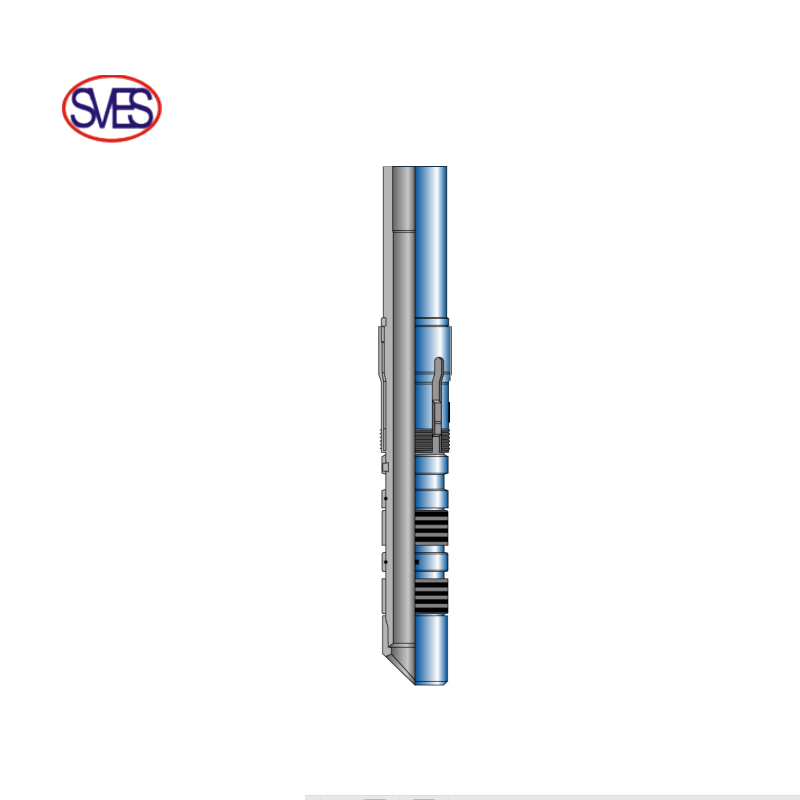

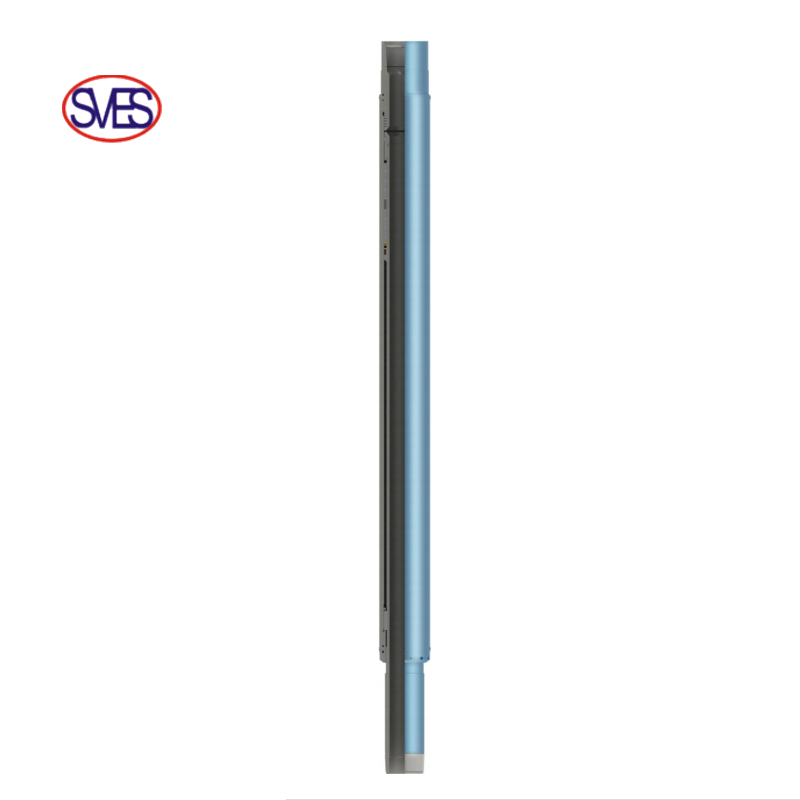

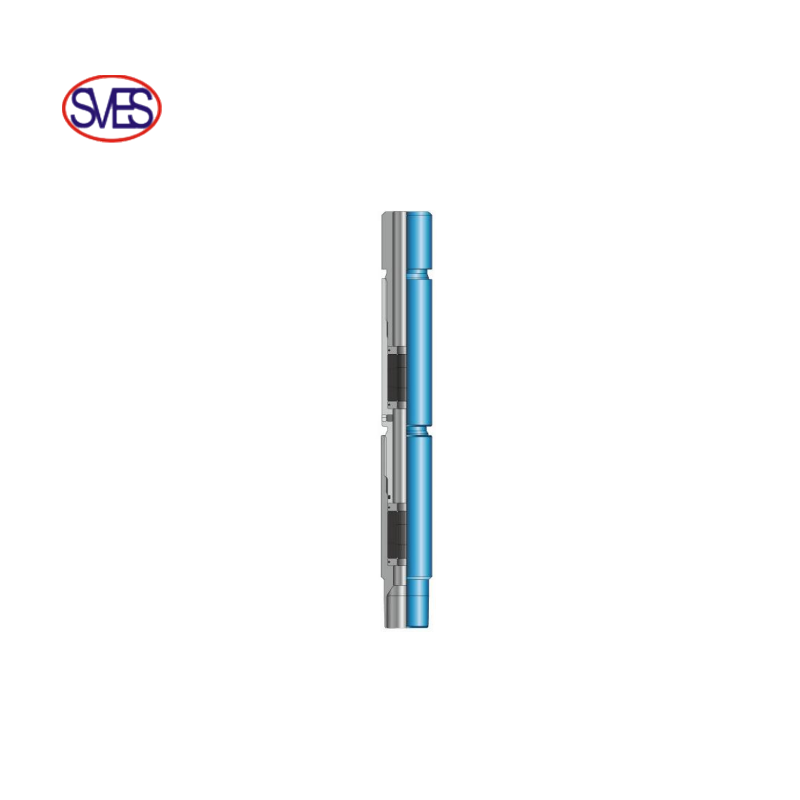

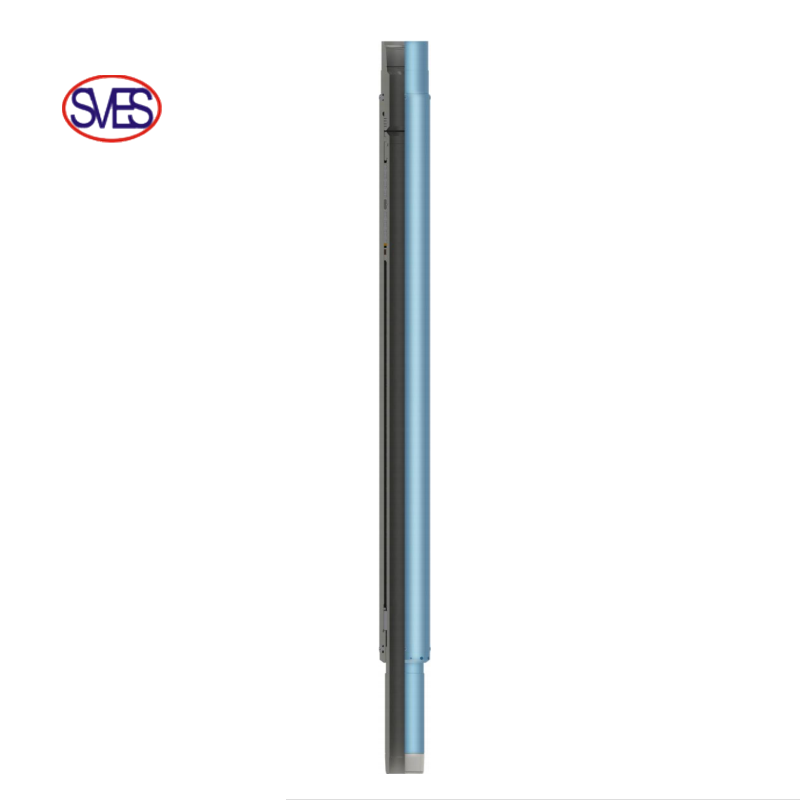

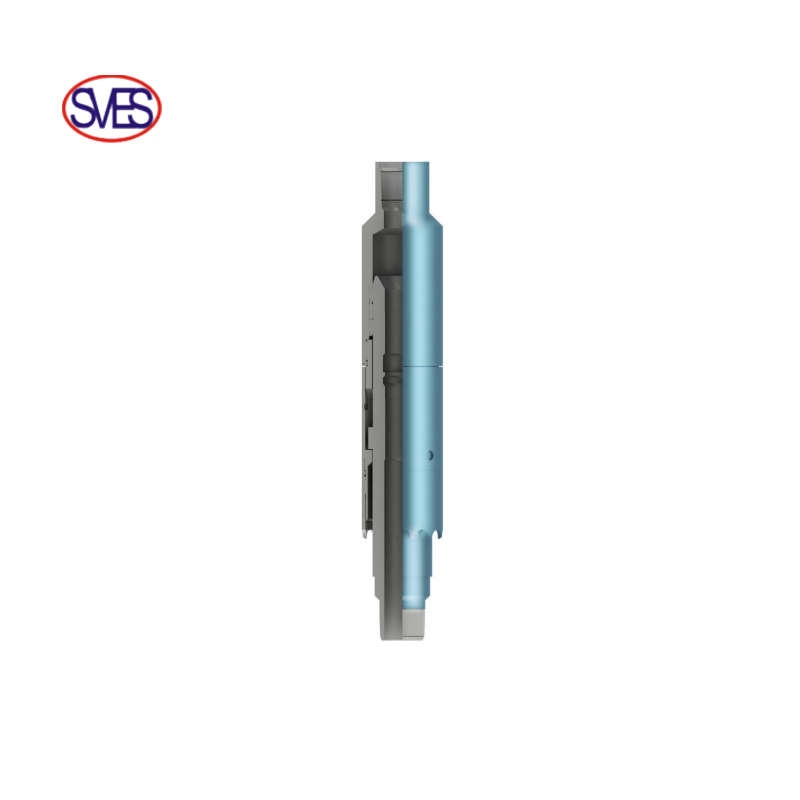

Travel Joints are made up in the tubing string and run into the well with packers and other down hole flow control equipments, and provide alternate methods of compensating for tubing contraction and elongation in producing, inj ection, and disposal wells. The travel joint are pinned in the closed, mid, or extended position before running. They also are keyed to prevent future rotation. The joints without keys are used when tubing torque below the joint is not required.

These travel joints can be pinned at any point in the stroke. The release value can be varied by the number of shear screws and can be sheared by tension or compression.

Features and Benefits

• Compensating tubing moving in various conditions

• Adjusted shear value

• Can be locked in open, mid-stroke, or closed positions

• ID of the tool is compatible with tubing ID

• Rotation is available by keyed type

Technical Data

Size | OD | ID | Stroke | ||||

In. | mm | In. | mm | In. | mm | ft | m |

2 7/8 | 73.03 | 4.28 | 108.71 | 2.42 | 61.47 | 10 | 3.05 |

20 | 6.10 | ||||||

3 1/2 | 88.90 | 4.78 | 121.41 | 2.90 | 73.66 | 10 | 3.05 |

20 | 6.10 | ||||||

4 1/2 | 114.30 | 5.80 | 147.32 | 3.88 | 98.55 | 10 | 3.05 |

20 | 6.10 | ||||||

* Other sizes available depending on tubing size selected and request.

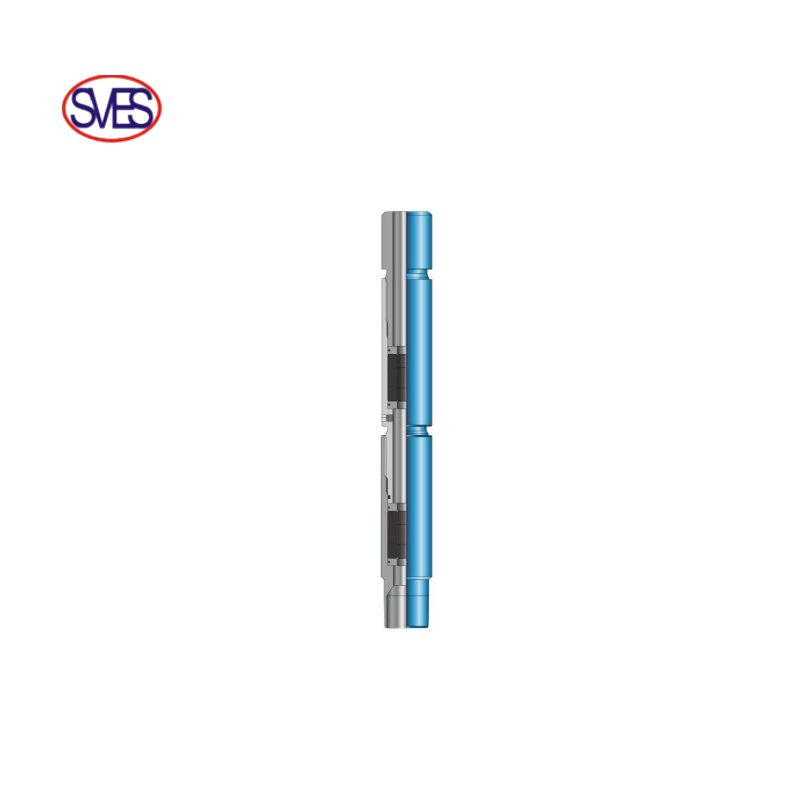

Star,s on-off tool enables the tubing string above packer be disconnected for lower zone isolation, tubing retrieval, and temporary zone abandonment. The tool,s stringer or seal receptacle contains an internal “SX or "SR” lock profile for landing the wire line blanking plug for zone isolation below the packer.

The tool consist of two major components: the Overshot mounted below tubing string and the stinger/receptacle mounted on the top of packer. The Overshot is disengaged by the Left or Right hand J-slot release. The mill bottom allows cuts through debris for easy engagement the stinger. Moulded seals are installed in the overshot, enable easy redress on surface for the re-run.

Features and Benefits

• Enables the packer used as bridge plug for lower zone isolation, or removal of upper string for redress, temporary abandonment or shut down lower zones, or kill the well.

• Bonded seals enable reliable multiple disconnections without costly retrieval replacement.

• The rugged, dependable design enables easy “right or Left Hand” rotational retrieval without disturbing the packer.

• Automatic 1/4 turn set down and tension for jay engage or jar out.

The Tie-Back Packer is a liner top packer that is most frequently run on drill pipe to repair a liner lap leak or for a mono-bore liner top completion, using a mechanical setting tool and a liner setting sleeve. Upon running into the existing liner polished bore extension, the integral seal stem at the bottom is inserted until seated and pressure tested down the work string. Additional slack off weight trips the collect lock nose and actuates the upper annular seal element, forming a pressure tight seal between the annulus of the casing and the liner.

The seal and slips used on the Tie-Back Packer is ideal for “Mono-bore” type applications, while the straight slack off weight setting mechanism eliminates pipe rotation, hydraulic setting ports and/or temporary plugging devices to set the packer.

Features and Benefits

• Full Bore single mandrel provides an unrestricted ID to the liner top once in place.

• Innovative patented seal offers unsurpassed pressure and temperature ratings and rugged dependability. The bonded elastomer/metal seal element is highly resistant to swab-off and mechanical damage while running in the hole.

• Proprietary seals on the seal stem ensure high-pressure integrity even after repeated hot stabling into the liner polished bore extension. Due to its rugged design, the Seal is less susceptible to damage while stabbing and un-stabling under pressure versus the conventional V-type packing.

• Patented Dual-Set Slips provide maximum bold down and up capabilities without damaging casing or packer mandrel.

• Useful as a liner top packer when running scab or tieback liners to surface.

• Collect lock nose feature prevents pre-setting while running in the hole.

• Positive set is held by internal body lock ring.

• Withstands high pressures and temperatures.

• Ideal for Monobore type liner top completions.

• Unique dual slip design eliminates tubing forces from being transferred into the packer element.

The HRS Liner setting tools provide the physical attachment between the running string and the liner. The setting tool is run in conjunction with a liner setting sleeve or liner top packer with the corresponding setting tool profile.

Features and Benefits

• Rotational or hydraulic releasing mechanisms are field-proven and available to fit a wide variety of applications

• Rugged designs result in high tensile load and torque capacities

• Torque fingers on certain tools permit liner to be rotated, helping to work liner to bottom or allowing rotation during cementing for improved placement of slurry