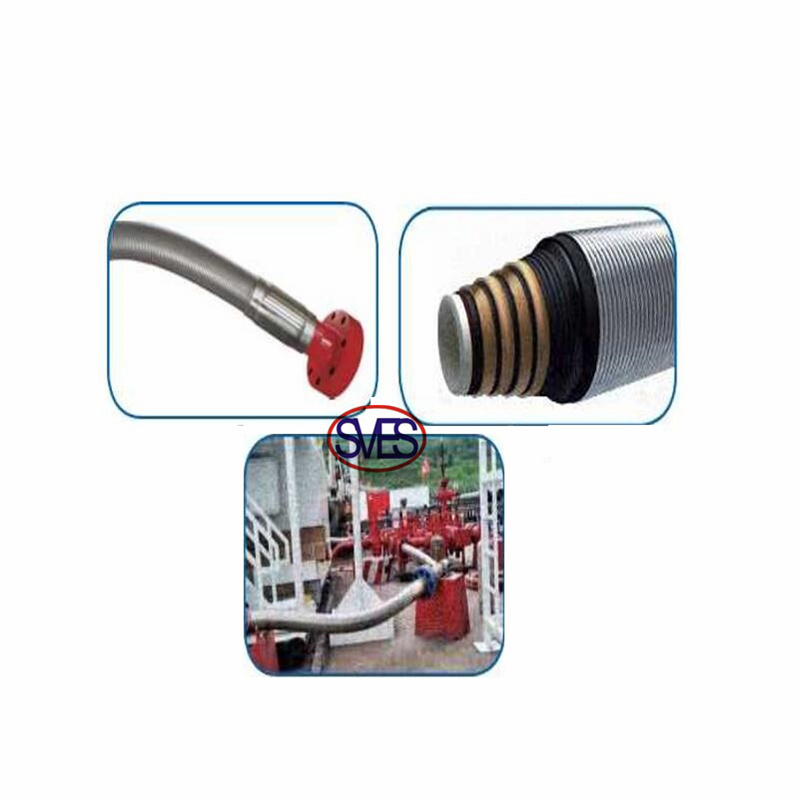

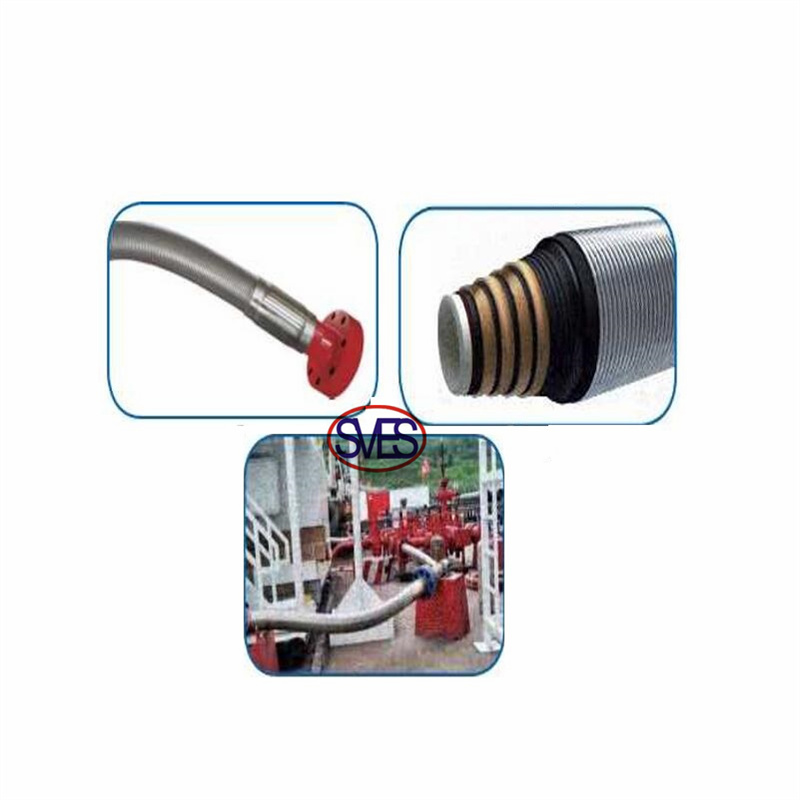

High Pressure Mud And Cement Hose

High Pressure Mud And Cement Hose

Rotary Drilling & Vibrator Hoses

Liner material HNBR /NBR / PA

Operating temperature -29°C to +121C (-20 T to 250 °F )

Flexible Specification Level FSLO to FSL3

Hose feature Resist abrasion, corrosion, oil, drilling muds, methane & H2S Standard: API Spec 7K

Couplings: Hammer unions / Thread / Flange

Options: Safety clamps / Hose lift eyes / Stainless steel armor

Flexible Choke & Kill Lines

Liner material HNBR / NBR / PA

Operating temperature -29°C to +121°C (-20 °F to 250 °F)

Survival temperature 177°C (350 °F ) for at least 1 hour Flexible Specification Level FSLO to FSL3

Hose feature Resist abrasion, corrosion, oil, drilling muds, methane & H2S

Standard: API Spec 16C

Couplings: Flange / Hammer union / Thread

Options: Safety clamps / Hose lift eyes / Stainless steel armor

High pressure Hydraulic Hoses

Liner material Black NBR Rubber

Reinforcement 4 or 6 Wire Spirals

Cover Flame retardant CR/Stainless steel armor

Operating temperature -40°C to +100°C (-104 T to212 °F )

Survival temperature 800 degree(1472 °F ) for 5 minutes

Hose feature Oil resistant/High temperature resistant/Ageing resistant

Standard: API Spec 16D

Couplings: NPT thread

Options: Quick coupling/Self - sealing union/Swivel elbow

Flexible Metal Hose Series

Stainless steel metal hose used for conveying all kinds of medium is a kind of flexible element made up of stainless steel ripple hose consisting of outer braided layer, one or multilayer wire or steel belt net. with joints or flanges at both ends. Its characteristic is: corrosion-resistance, high temperature resistance, low temperature resistance(-196 °C to+420 °C ), light weight, small volume, and good flexibility. It is widely used in aviation, spaceflight, oil, chemical industry, metallurgy, power, papermaking, wood, textile, building, medicine, food, tobacco, traffic and etc。

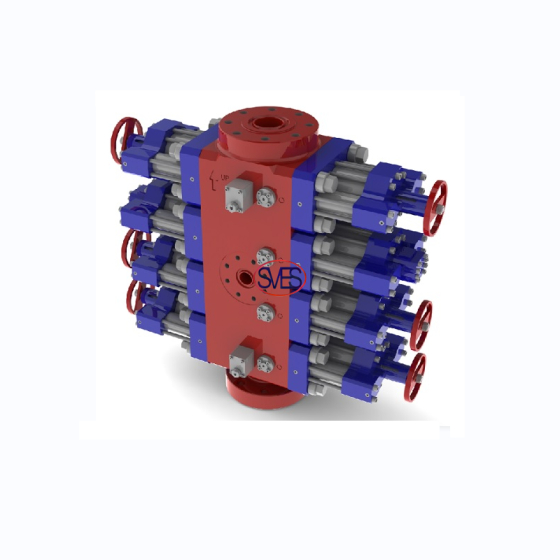

Compensator Series

The function of compensator is to compensate the size change of pipeline, catheter and container due to heat expansion and cold contraction, or to compensate the axial, transverse and angular displacement of pipeline, catheter and container. It can also be used to reduce noise and vibration.In the heating system, in order to prevent the deformation or damage of the pipe caused by thermal elongation or thermal stress when the heating pipe is heating, a compensator should be set on the pipe to compensate the thermal elongation of the pipe, so as to reduce the stress on the pipe wall and the acting force on the valve or bracket structure.Compensator is widely used in chemical industry, metallurgy, thermal power generation, urban heating and other industries.