Inside Blowout Control Tools

Inside BOP Valve is a large pressure drop check valve, the tapered plug of valve, reduce the cutting action of the mud on the seat to ensure the closed position. Inside BOP Valve connected with drill string can protect swivel, hose and standing pipe. It can also be used as a releasing tool to make the valve opening , and allows the back flow through.This optional release tool is installed in the float valve and the whole assembly is kept ready on the platform for quick installation at the frist thing when drill pipe is pulled out of the well

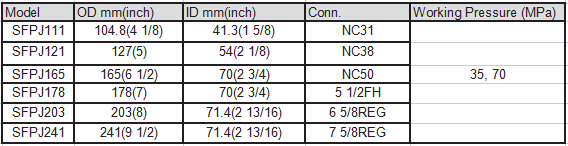

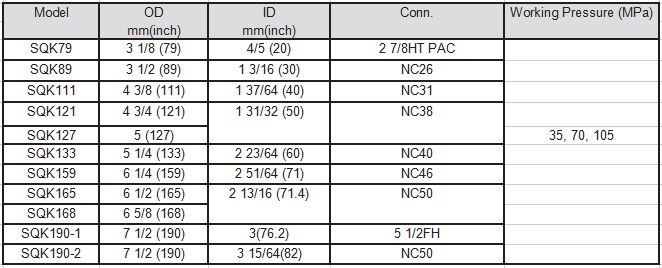

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

Float valve is one of necessary tool for oil drilling,it consists of float valve sub and float valve, The main function are to prevent drill cuttings come into mud when connecting each joint and the bit bore block caused by back flow of silt.When the well blowout or kick,the valve cover of float valve turn off the bore automatically,it will prevent well blowout accident.The working pressure of float valve is supposed to be 5000psi or 10000psi.

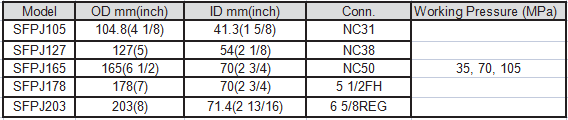

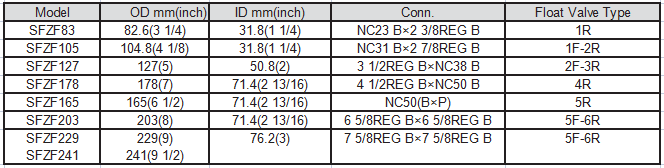

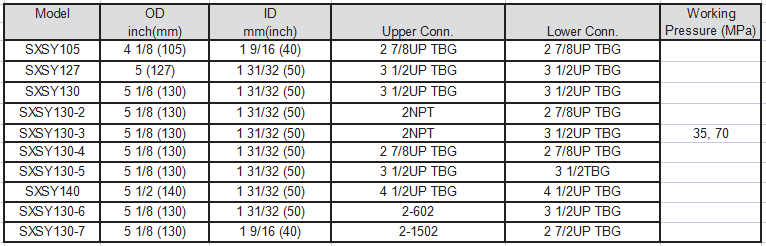

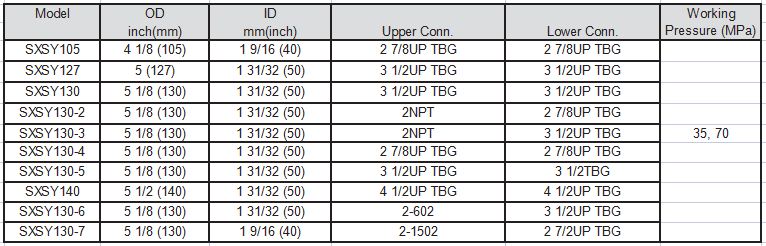

Float Valve Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

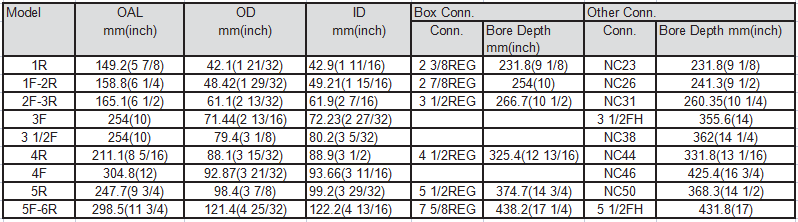

Float Valve Sub Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

Full opening safety valve is one of the effective tools to prevent blowout as well as it is a hand control valve in drill string circulating system, and it is one of the effective tools to prevent blowout. In the drilling operation, in order to avoid accidents, full opening safety valve shall be connected between drill pipes in drilling process. The special wrench of full opening safety valve may rotate 90 °according instruction to switch on and off. In well repair operation, whether need to lift the drill pipe or not, it is best to install opening safety valve as prevention.

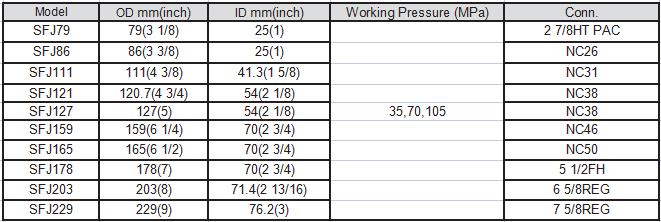

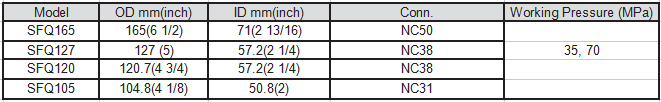

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

Tubing valve is called as tubing cock, the drilling fluid can flow through the vale without pressure drop. This valve is used as the tubing valves and install above tubing to control blowout or to prevent drilling fluid loss when unload the tubing.

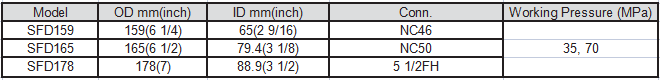

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

Kelly valve is divided into Upper Kelly Valve and Lower Kelly Valve. Upper Kelly Valve is connected between swivel sub and Kelly. Lower Kelly valve is connected between lower end of Kelly and top of drill pipe or lower end of Kelly save sub. Kelly valve also called Kelly cock or drill pipe safety valve. It is a hand control valve in drill string circulating system and it is one of the effective tools to prevent blowout.

Rotating the wrench of full opening safety valve 90° to realize on and off. In the drilling operation, in order to avoid malignant accidents, Kelly valves should be connected to both end of Kell to prevent loss of diilling fluid and blowout.

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

When we say drilling string Check Valve that including the following type of Valves: Arrow Type Check Valve, Ball Check Valve, Drop-in Check Valve, Retrievable Drop-in Check Valve,Plate Check Valve.

Arrow Type Check Valve

Arrow type check valve (drill check valve) is a kind of important inside blowout tool, usually used in the oil and gas drilling and workover. It works with the drilling tool into the well, in the process of drilling and workover in case of overflow, kick, or positive cycle to stop, the arrow type check valve will shut down rapidly under the action of reverse circulation pressure inside drill tools and spring force, cutting the channel within drilling tools, thus play a blowout purpose within drill tools.

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

In order to realize safety control in drilling operation.Ball Check Valve can effectively solve the overflow, Put it into the well with drill stem and control the mud back flow pressure automatically.So Ball check valve is a wellhead inside blowout tool.

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

Compared with other structure standing by pressure valve.Plate check valve is an important blowout control tool,it has high strength,large flow area, high temperature resistant to high pressure,drilling fluid corrosion resistance and easy maintenance,etc

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.

4. Retrievable Drop-In Check Valve, Drop-In Check Vavle

4.1 Retrievable drop-in check valve is a drill string inside BOP valve. It has a landing sub and connected to the right position of drill string, then put into the well, to help the check valve assembly into place. Retrievable drop-in check valve is one kind of one way check valve to prevent backflow when well kick. It allows fluid down to return well.This valve can comtrol pressure in the drilling process and improve the well control obviously. As long as drop in, it can be into place on the land sub automatically, easy operate, so that achieve the purpose of the blowout control. In addition, compared with other previous drop- in check valve, the disassembly of this check valve can save a lot of manpower and material resources.

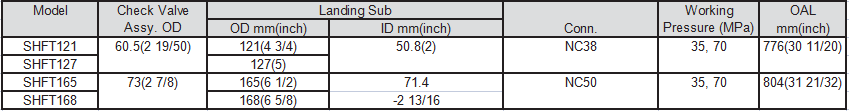

Specification:

4.2 Drop-In Check Valve has a landing sub, which connect to the need position of drill string then put into the well, help check valve into place, drop-in check valve is a kind of single flow check valve, stored on the platform, when found blowout happened, drop it into drill pipe bore, just droping the Drop-In Valve, that can be set into place on the land sub automatically, when high pressure flow of downhole, the check valve could cut off high pressure flow of upward jet in the drill string.

Drop-in check valve is a drill string inside BOP valve. It also can be used for blocking off drill pipe on all kinds of offshore drilling floating equipment. Only after blocking off bore hole and the annular space outside the drill string, that can be complete tasks to prevent blowout accident, as long as blocking off high pressure flow in the bore of drilling string, the well blowout is easy to control which occurred between bore hole and the annular space outside the drill string.

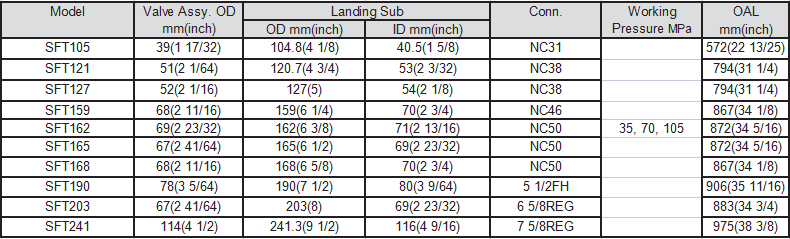

Specification:

Enquiry from client should including the following: Sizes, working pressure, connections; Please specify special requirements if any.